Economical long service life material for mechanical press forging die and manufacturing method thereof

A manufacturing method and long-life technology, applied in the direction of manufacturing tools, furnace types, heat treatment process control, etc., can solve the problems of affecting the service life, increasing the use temperature of molds, and low forging time and output of small steel ingots. Hardness, increased heating speed, and the effect of saving valuable elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

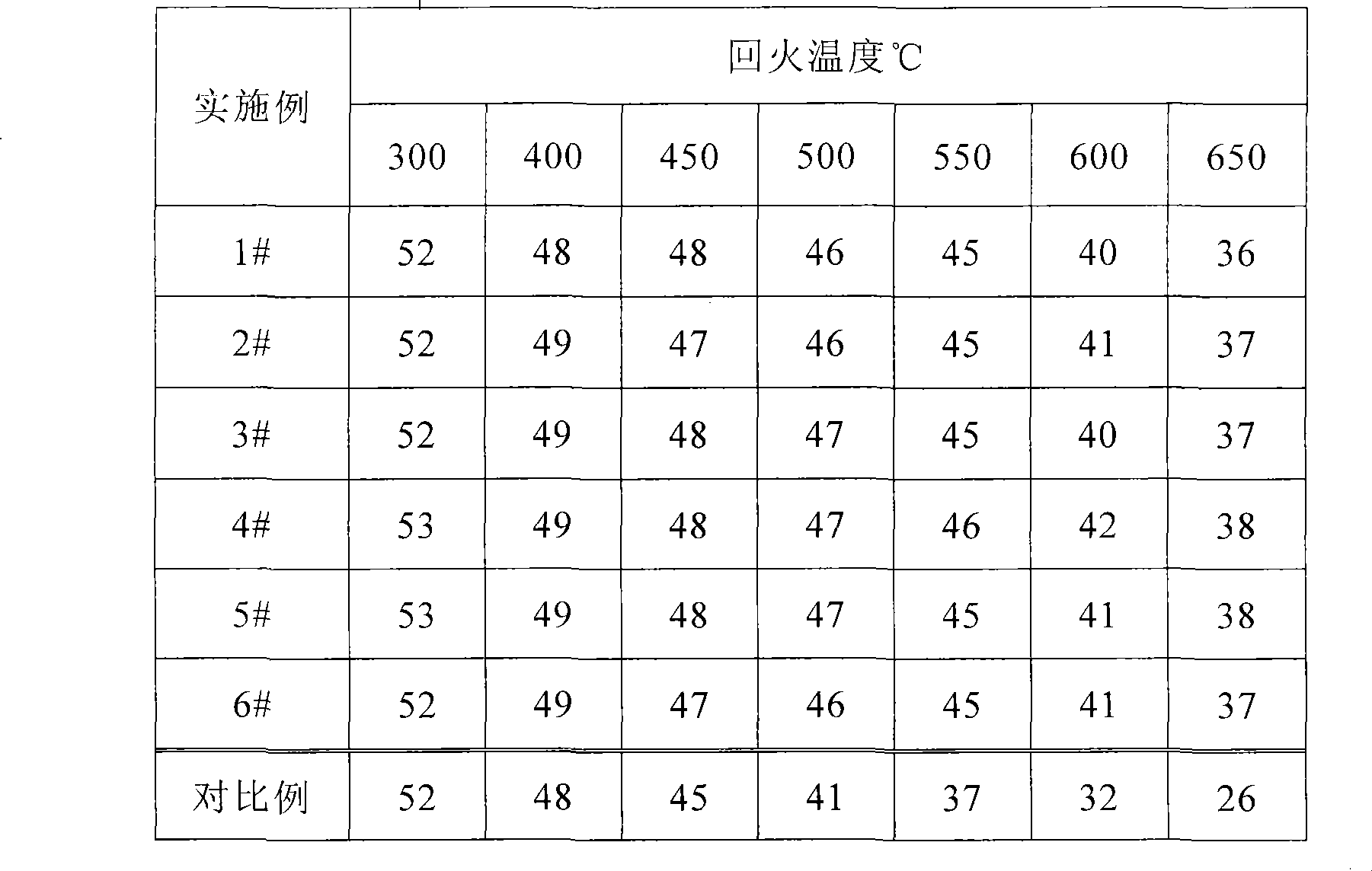

Examples

Embodiment 1

[0065] The chemical composition weight percent of steel is C 0.42, Si 0.24, Mn 0.85, Cr 1.95, V 0.19, Mo 0.47, Ni 0.35, Cu 0.12, Ti 0.03, Al 0.028, P 0.010, S 0.005, N 0.0085, and Fe.

[0066] After electric furnace smelting, out-of-furnace refining and vacuum degassing treatment, 13.5 tons of steel ingots are cast. The steel ingots are heated in the heating furnace of the fast forging machine. The temperature of the steel ingots entering the furnace is 750 ° C. After heating to 1230°C, heat preservation for 5 hours;

[0067] Forging process:

[0068] Upsetting operation, upsetting to 1 / 2 of the original height of the ingot, starting forging temperature is 1170°C, final forging temperature is 1060°C; drawing operation, forging to finished product size, starting forging temperature is 1030°C, final forging temperature is 870°C , forging ratio 5.3.

[0069] The concrete chemical composition (wt%) of embodiment 2~6 is shown in table 1, and process parameter control is according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com