Austenitic stainless steel having improved hydrogen embrittlement resistance, and high-pressure hydrogen gas container comprising same

An austenitic system and high-pressure hydrogen technology, which is applied in the direction of pressure vessels, outer walls of vessel structures, fluid treatment, etc., can solve the problems of corrosion resistance and mechanical performance degradation, achieve excellent resistance to hydrogen embrittlement, reduce manufacturing costs, reduce Effect of Ni content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

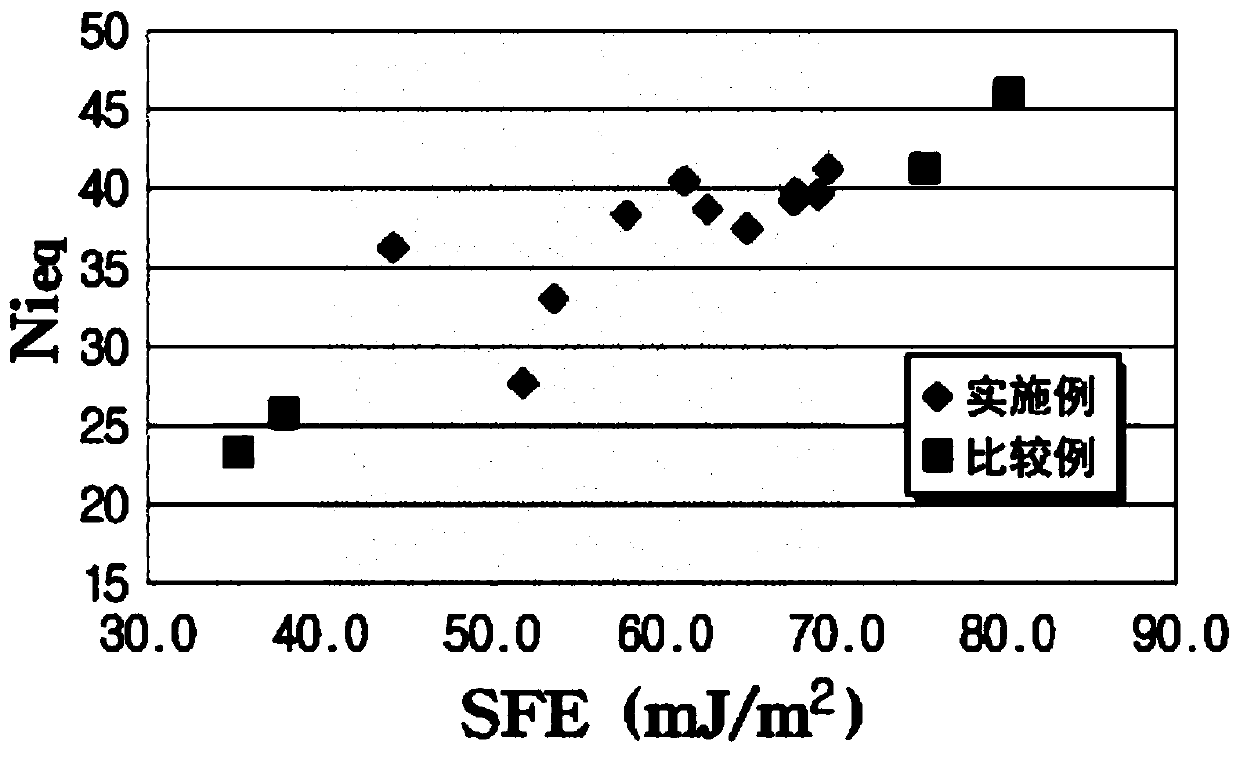

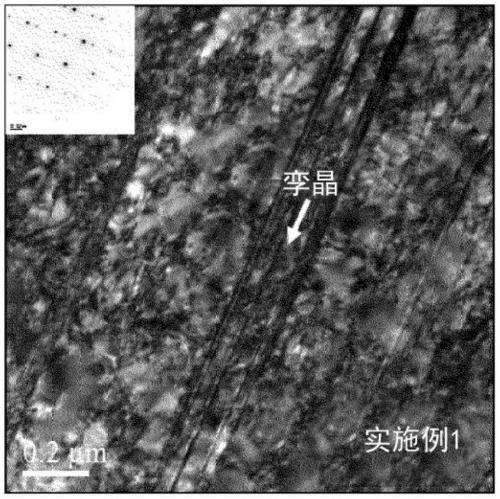

[0095] The SFE of embodiment 1 is 57.8mJ / m 2 , belongs to 40~70mJ / m 2 In the range of , so as to produce twins (Twin) in the strain, the SFE of comparative example 4 is 75.2mJ / m 2 , exceeding 40~70mJ / m 2 range, resulting in HDDW rather than twinning in strain.

[0096] From the results of Example 11, it can be seen that when Nb is added, crystal grains are refined, and the tensile strength shows a high value of 840 MPa or more.

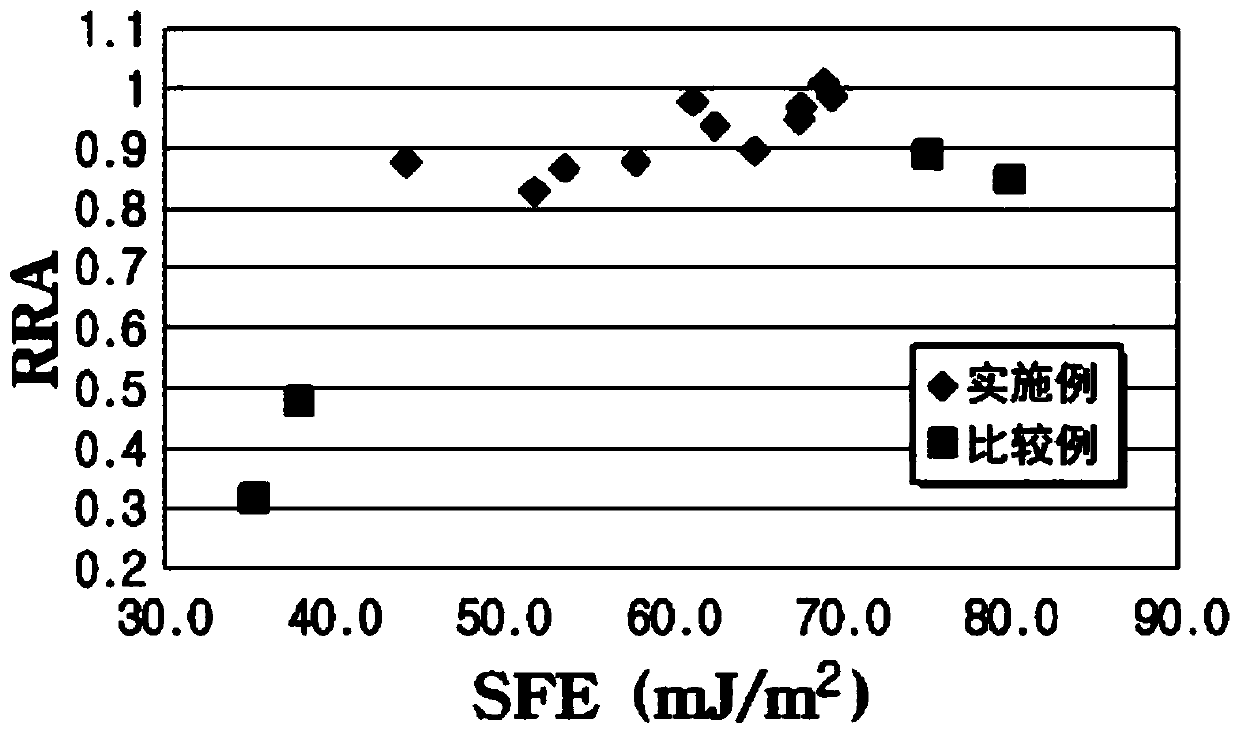

[0097] From the results of Example 6, it can be seen that by adjusting the austenite stabilizing elements, the Ni of 27 or more required in the present invention can be obtained eq , so that a low strain-induced martensite fraction of less than 1% can be obtained even in a high-pressure hydrogen environment, and excellent hydrogen embrittlement resistance with an RRA of 0.8 or more can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com