A-site Pr doping BTO film material and preparation thereof

A kind of thin film material and thin film technology, which is applied in the field of preparation of A-site Pr-doped BTO thin film by radio frequency magnetron sputtering process, can solve the problems that the preparation method has not been published by the prior art, and achieve the purpose of suppressing component segregation and compensating for volatilization Loss, the effect of preventing warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

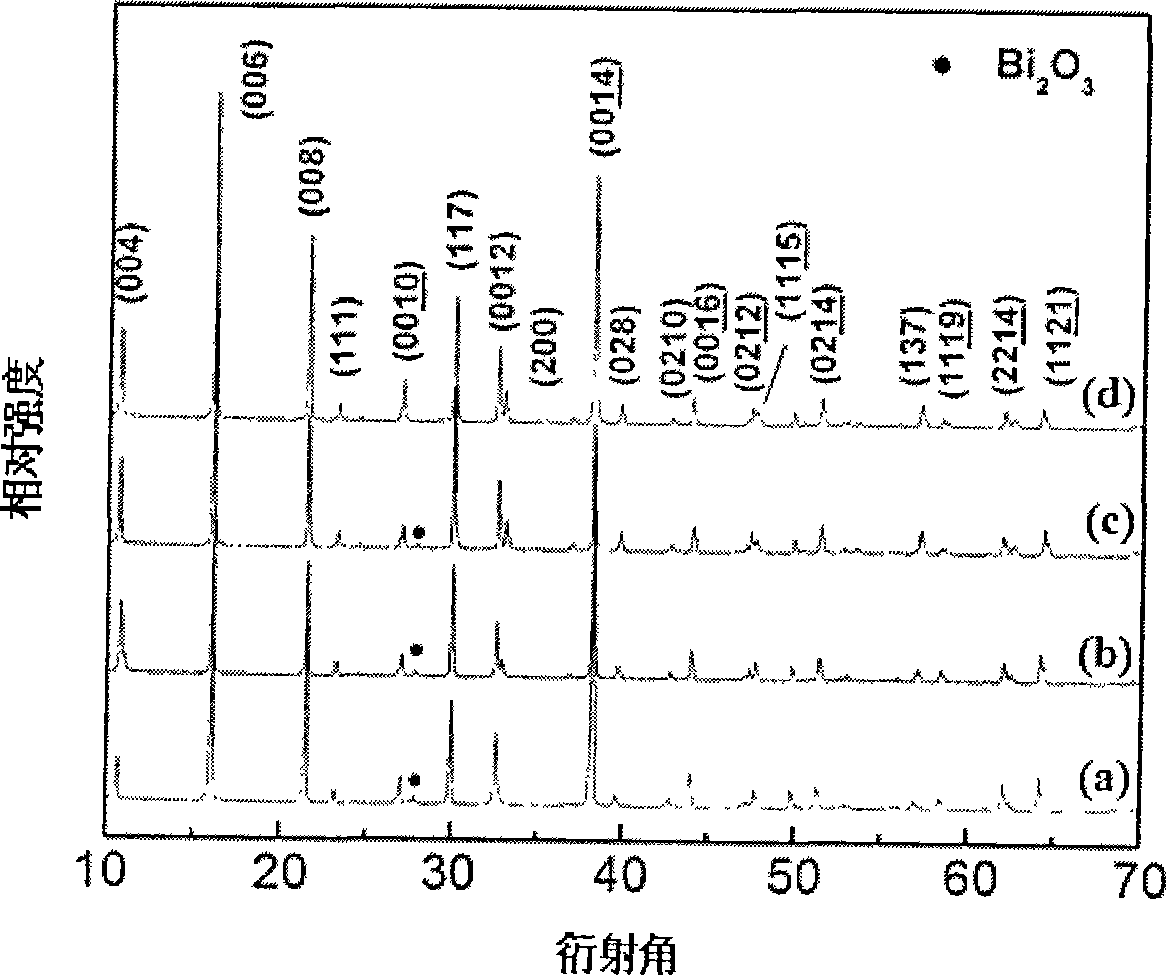

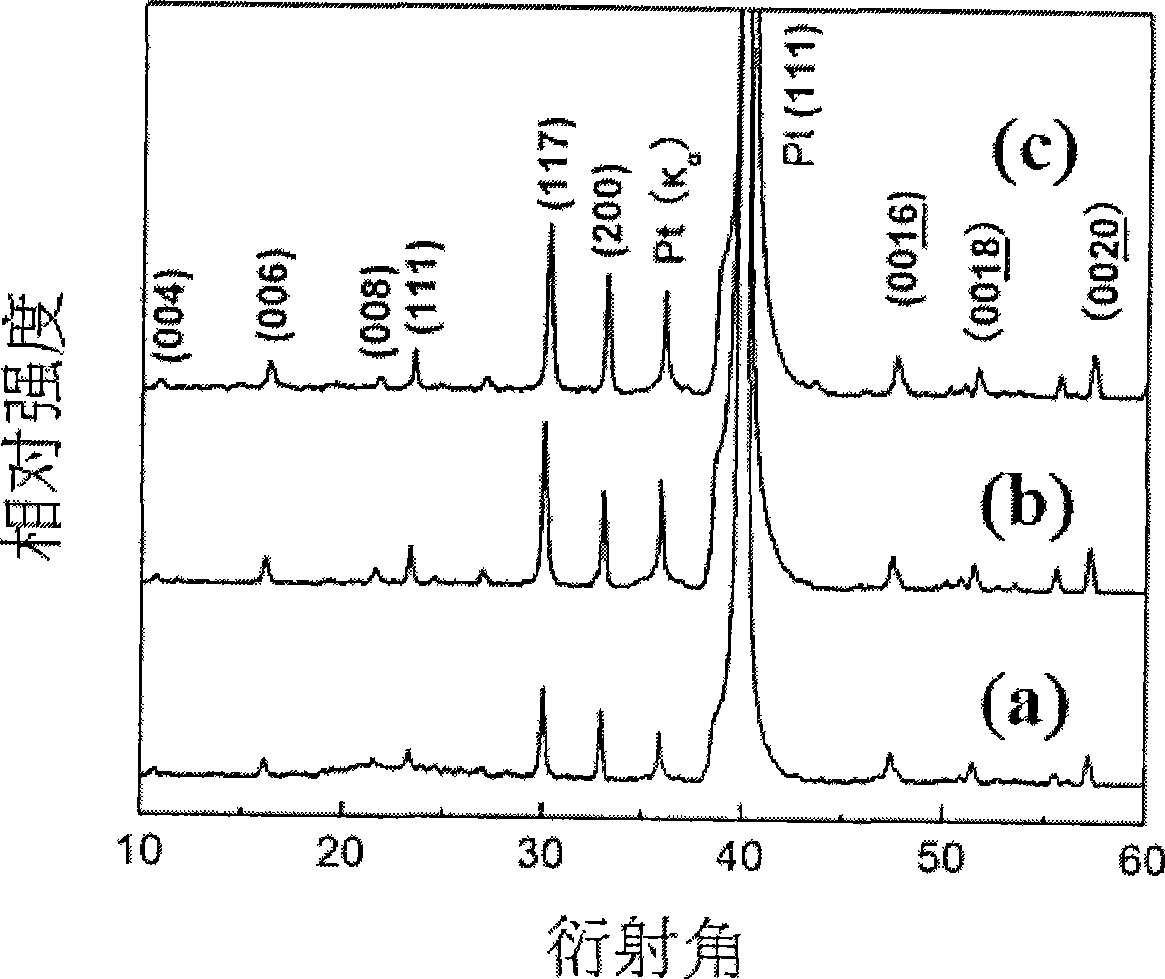

[0033] Example 1 Preparation of pure Bi under the first parameter 2.9 PR 0.9 Ti 3 o 12 (x=0.9) target and film

[0034] (1) adopt following raw material (its purity is analytically pure, more than 99.9% of purity), use solid phase reaction method to prepare pure Bi for radio frequency magnetron sputtering 2.9 PR 0.9 Ti 3 o 12 target;

[0035] Considering that Bi is volatile at high temperature, the Bi 2.9 PR 0.9 Ti 3 o 12 On the basis of the ideal chemical composition ratio, the composition formula with an excess of 5% Bi is used to compensate for the volatilization loss of Bi.

[0036] bismuth trioxide Bi 2 o3 : Oxidation spectrum Pr 6 o 11 : Titanium dioxide TiO 2 =1.552:0.15:3

[0037] The specific method is:

[0038] 1.1) The weighed Bi 2 o 3 、TiO 2 and Pr 6 o 11 Mix the powder evenly, put it into an agate mortar, and grind it until the powder is uniform khaki; considering Bi 2 o 3 、TiO 2 and Pr 6 o 11 Due to the huge (several times) difference i...

Embodiment 2

[0059] Example 2 Preparation of pure Bi under the second parameter 3.6 PR 0.3 Ti 3 o 12 (x=0.3) target and film methods

[0060] (1) adopt following raw material (its purity is analytically pure, more than 99.9% of purity), use solid phase reaction method to prepare pure Bi for radio frequency magnetron sputtering 3.6 PR 0.3 Ti 3 o 12 target;

[0061] Considering that Bi is volatile at high temperature, the Bi 3.6 PR 0.3 Ti 3 o 12 On the basis of the ideal chemical composition ratio, the composition formula with an excess of 6% Bi is used to compensate for the volatilization loss of Bi.

[0062] bismuth trioxide Bi 2 o 3 : Oxidation spectrum Pr 6 o 11 : Titanium dioxide TiO 2 =1.908:0.05:3

[0063] The specific method is:

[0064] 1.1) The weighed Bi 2 o 3 、TiO 2 and Pr 6 o 11 Mix the powder evenly, put it into an agate mortar, and grind it until the powder is uniform khaki;

[0065] 1.2) Add 35ml of acetone, use a planetary ball mill for 12 hours, cont...

Embodiment 3

[0085] Example 3 Preparation of pure Bi under the third parameter 3.4 PR 0.5 Ti3 o 12 (x=0.5) Target and film methods, including:

[0086] (1) adopt following raw material (its purity is analytically pure, more than 99.9% of purity), use solid phase reaction method to prepare pure Bi for radio frequency magnetron sputtering 3.4 PR 0.5 Ti 3 o 12 target;

[0087] Considering that Bi is volatile at high temperature, the Bi 3.4 PR 0.5 Ti 3 o 12 On the basis of the ideal chemical composition ratio, the composition formula with an excess of 7.5% Bi is used to compensate for the volatilization loss of Bi.

[0088] bismuth trioxide Bi 2 o 3 : Titanium dioxide TiO 2 : Oxidation spectrum Pr 6 o 1 1=1.828:0.083:3

[0089] The specific method is:

[0090] 1.1) The weighed Bi 2 o 3 、TiO 2 and Pr 6 o 11 Mix the powder evenly, put it into an agate mortar, and grind it until the powder is uniform khaki;

[0091] 1.2) Add 35ml of acetone, and use a planetary ball mill to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com