Process for preparing Si base Bi4 Ti3 O12 ferroelectric film

A ferroelectric thin film, thin film technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

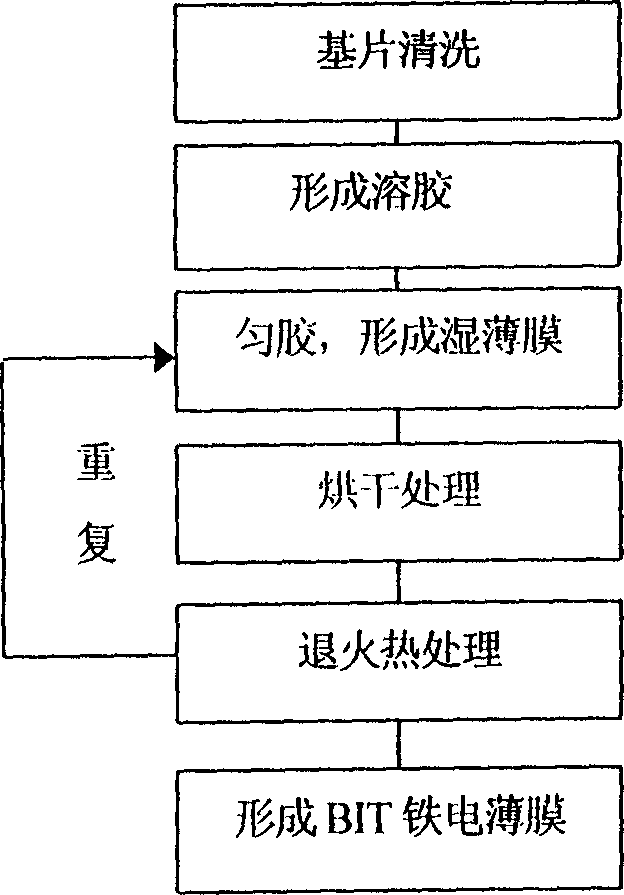

Method used

Image

Examples

Embodiment 1

[0041] (1) Select a p-type single crystal Si substrate with a resistivity of 3Ω cm and a (100) crystal orientation as the substrate, and perform surface treatment and cleaning according to the requirements of the semiconductor plane process;

[0042] (2) adopt the following raw materials (its purity is analytically pure 99.9%) to prepare Bi 4 Ti 3 o 12 Sol:

[0043] Butyl titanate (C 16 h 36 o 4 Ti) 5.11ml

[0044] Glacial acetic acid (CH 3 COOH) 6.00ml

[0045] Bismuth nitrate (Bi(NO3) 3 ·5H 2 O) 10.67g

[0046] Acetylacetone (C 16 h 36 o 4 Ti) 38.00ml

[0047] The specific method is:

[0048] (2.1) Put the weighed bismuth nitrate into the beaker;

[0049] (2.2) adding glacial acetic acid;

[0050] (2.3) Stir with a magnetic stirrer to make it react evenly and fully until the bismuth nitrate is completely dissolved;

[0051] (2.4) Butyl titanate (C 16 h 36 o 4 Ti) put into another beaker;

[0052] (2.5) Add an appropriate amount of acetylacetone to make ...

Embodiment 2

[0063] Embodiment 2: (the purity of each raw material is required to be more than 99.9% of analytical purity)

[0064] 1) Select a p-type single crystal Si substrate with a resistivity of 5Ω cm and (100) crystal orientation as the substrate, and perform surface treatment and cleaning according to the requirements of the semiconductor planar process;

[0065] (3) adopt the following raw materials (its purity is analytically pure 99.9%) to prepare Bi 4 Ti 3 o 12 Sol:

[0066] Butyl titanate (C 16 h 36 o 4 Ti) 5.11ml

[0067] Glacial acetic acid (CH 3 COOH) 15.00ml

[0068] Bismuth nitrate (Bi(NO3) 3 ·5H 2 O) 10.40g

[0069] Acetylacetone (C 16 h 36 o 4 Ti) 32.00ml

[0070] The specific method is:

[0071] (2.1) Put the weighed bismuth nitrate into the beaker;

[0072] (2.2) adding glacial acetic acid;

[0073] (2.3) Stir with a magnetic stirrer to make it react evenly and fully until the bismuth nitrate is completely dissolved;

[0074] (2.4) Butyl titanate (C...

Embodiment 3

[0084] Embodiment 3: (the purity of each raw material is required to be more than 99.9% of analytical purity)

[0085] 1) Select a p-type single crystal Si substrate with a resistivity of 10Ω cm and (100) crystal orientation as the substrate, and perform surface treatment and cleaning according to the requirements of the semiconductor planar process;

[0086] (4) adopt the following raw materials (its purity is analytically pure 99.9%) to prepare Bi 4 Ti 3 o 12 Sol:

[0087] Butyl titanate (C 16 h 36 o 4 Ti) 5.11ml

[0088] Glacial acetic acid (CH 3 COOH) 30.00ml

[0089] Bismuth nitrate (Bi(NO3) 3 ·5H 2 O) 10.50g

[0090] Acetylacetone (C 16 h 36 o 4 Ti) 12.00ml

[0091] The specific method is:

[0092] (2.1) Put the weighed bismuth nitrate into the beaker;

[0093] (2.2) adding glacial acetic acid;

[0094] (2.3) Stir with a magnetic stirrer to make it react evenly and fully until the bismuth nitrate is completely dissolved;

[0095] (2.4) Butyl titanate (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com