Process for producing rubber vulcanization accelerant penta-methylene thiuram tetrasulfide

A technology of double-penta-tetrasulfide and rubber vulcanization, used in organic chemistry and other directions, can solve problems such as non-compliance with national environmental protection policies and energy-saving production requirements, products that are difficult to meet high-end requirements, and difficult to clean and green" production, and achieve excellent vulcanization performance. , The effect of reducing the pollution of the three wastes and shortening the vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

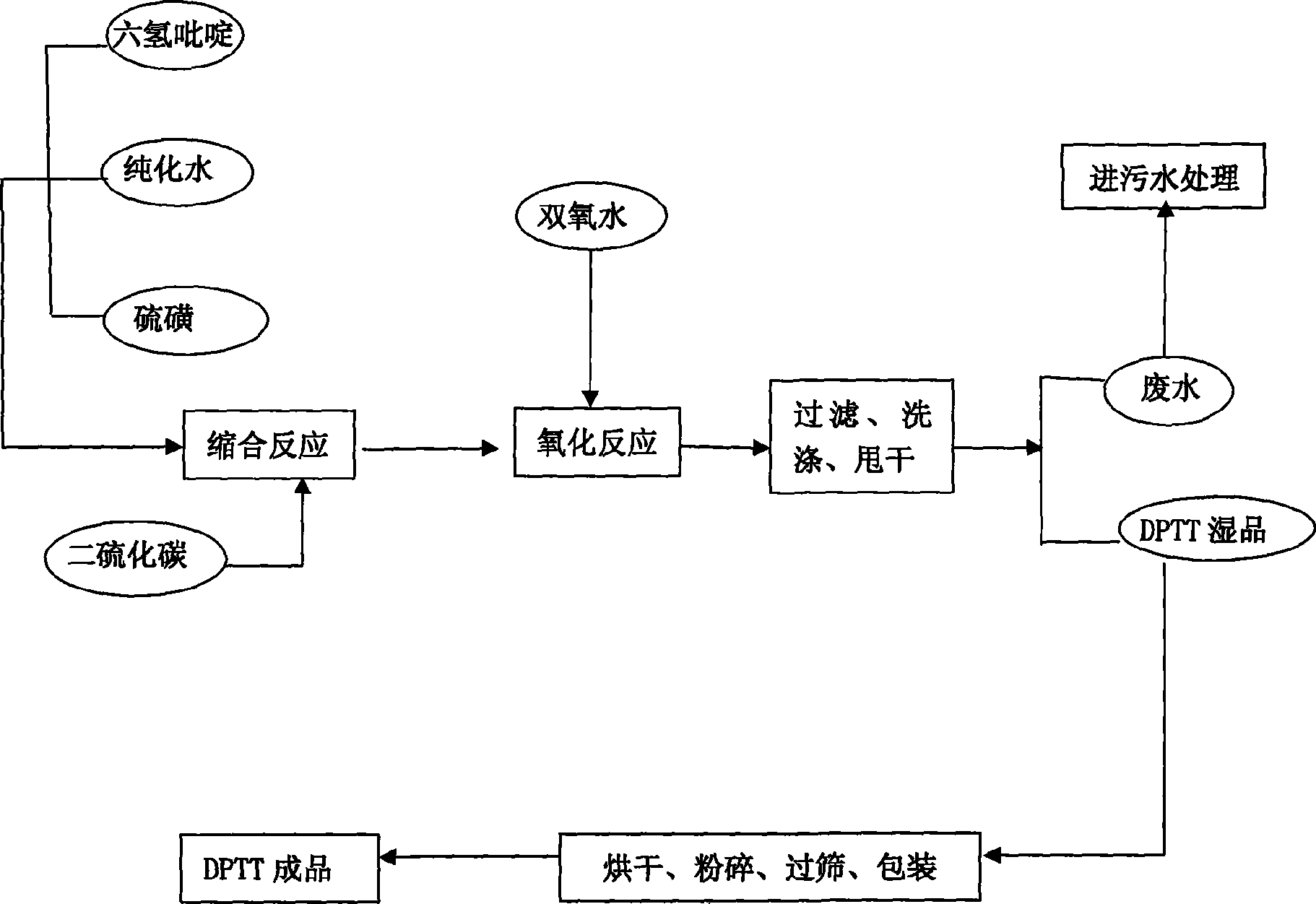

Image

Examples

Embodiment 1

[0029] The raw materials used in the preparation method of the rubber vulcanization accelerator of the present embodiment dipentamethylene thiuram tetrasulfide (DPTT) and their mol ratio are:

[0030] Hexahydropyridine: carbon disulfide: sulfur: hydrogen peroxide = 1: 1.1: 2.0: 0.5;

[0031] The specific process is: under normal pressure, add hexahydropyridine and sulfur to the reaction kettle filled with water in a stirring state, after the addition is completed, control the temperature to 23 ° C, then add carbon disulfide liquid dropwise, and control the dropwise addition After 2 hours, measure the pH value of the reaction solution after the dropwise addition. After the pH value of the reaction solution is stabilized to 6.8, control the temperature of the reaction solution to 30°C, and start to add hydrogen peroxide to carry out the oxidation reaction. The oxidation reaction time is 3 hours ; After the oxidation reaction is finished, heat the reaction for 1 hour, then separa...

Embodiment 2

[0033] The raw materials used in the preparation method of the rubber vulcanization accelerator of the present embodiment dipentamethylene thiuram tetrasulfide (DPTT) and their mol ratio are:

[0034] Hexahydropyridine: carbon disulfide: sulfur: hydrogen peroxide = 1: 1.2: 2.3: 0.6;

[0035] The specific process is as follows: under normal pressure, add hexahydropyridine and sulfur into the reaction kettle filled with water in a stirring state, control the temperature at 25°C after the addition, and then add carbon disulfide liquid dropwise, and control the dropwise addition The time is 2.6 hours. After the dropwise addition, measure the pH value of the reaction solution. After the pH value of the reaction solution is stabilized to 7.0, control the temperature of the reaction solution to 35°C, and start to add hydrogen peroxide to carry out the oxidation reaction. The oxidation reaction time is 3.5 hours ; After the oxidation reaction is finished, heat the reaction for 1 hour,...

Embodiment 3

[0037] The raw materials used in the preparation method of the rubber vulcanization accelerator of the present embodiment dipentamethylene thiuram tetrasulfide (DPTT) and their mol ratio are:

[0038] Hexahydropyridine: carbon disulfide: sulfur: hydrogen peroxide = 1: 1.3: 2.5: 0.6;

[0039]The specific process is: under normal pressure, add hexahydropyridine and sulfur to the reaction kettle filled with water in a stirring state, after the addition is completed, control the temperature at 28°C, then add carbon disulfide liquid dropwise, and control the dropwise addition The time is 2.8 hours. After the dropwise addition, measure the pH value of the reaction solution. After the pH value of the reaction solution is stabilized to 7.3, control the temperature of the reaction solution to 40°C, and start to add hydrogen peroxide to carry out the oxidation reaction. The oxidation reaction time is 4 hours. ; After the oxidation reaction is finished, heat the reaction for 1 hour, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com