Nickel-based boron-free brazing material and preparation thereof

A brazing material, nickel-based technology, applied in welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of complex manufacturing process, high cost, application limitations, etc., and achieve low cost, short cycle, preparation simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

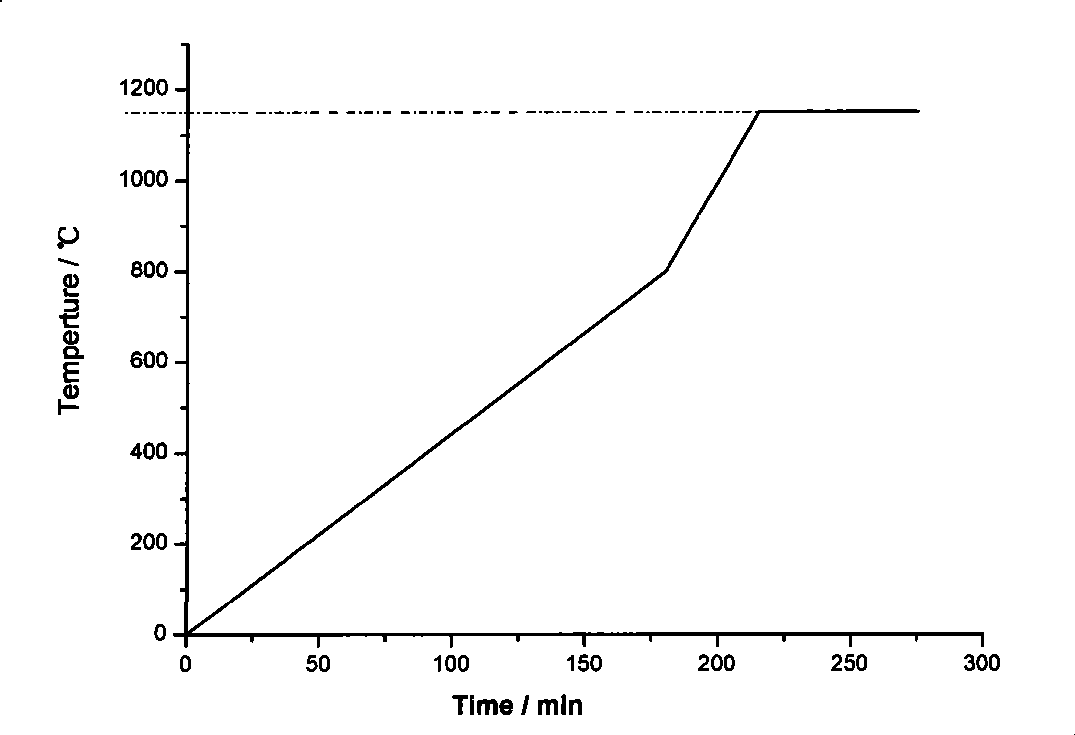

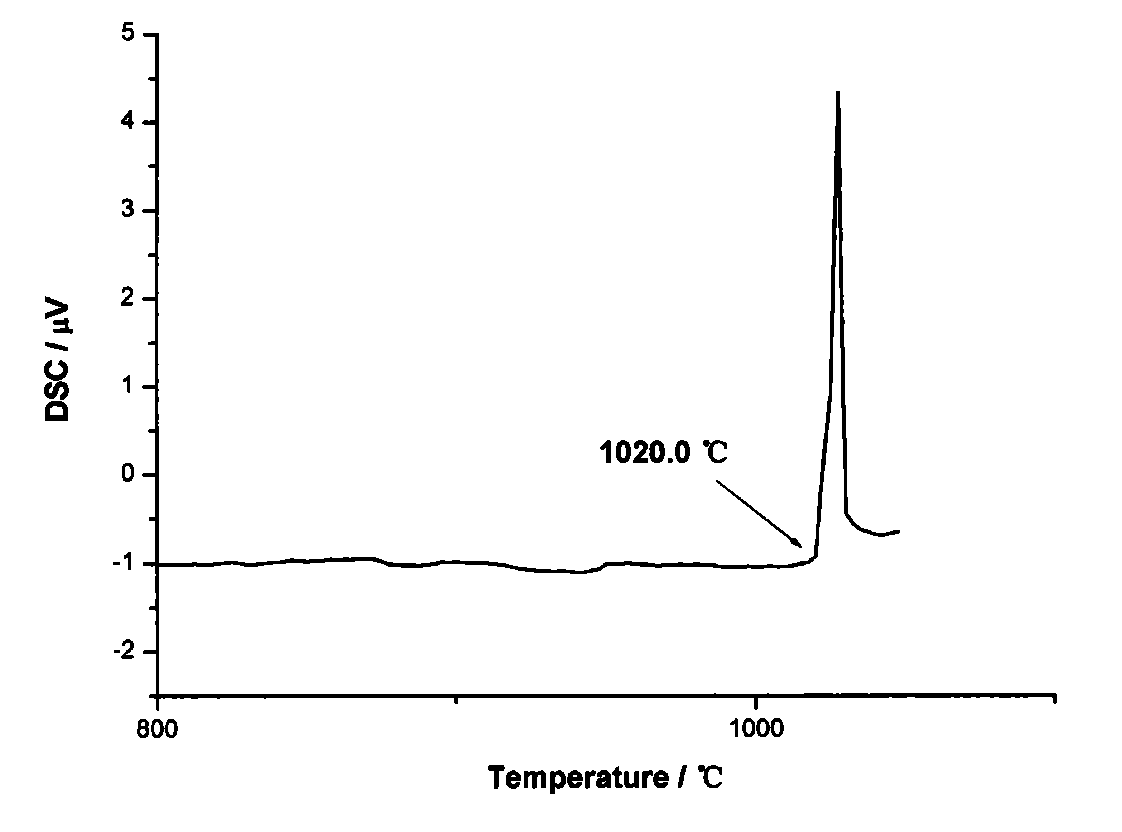

[0022] Embodiment 1: Preparation of Ni54.9Cr3Si2Zr14.4Sn25.6 solder alloy

[0023] Weigh 54.9% nickel with a purity of 99.9%, 3% chromium with a purity of 99.9%, 2% silicon with a purity of 99.9%, 14.4% zirconium with a purity of 99.9%, and 25.6% tin with a purity of 99.9%. After cleaning and weighing the above-mentioned chromium, silicon, zirconium, tin and nickel raw materials, they are alloyed by arc melting method under an inert gas protective atmosphere. The obtained button-shaped sample is preliminarily cut into strips and packed into a quartz tube to ensure that the vacuum in the quartz tube is below 1Pa, and then filled with high-purity argon to (0.7-0.8)×10 5 Pa. The packaged sample is put into a reaction furnace for stress relief annealing heat treatment at a temperature of 800° C. for 7 days to obtain the nickel-based boron-free medium-temperature solder alloy. After taking out the above-mentioned heat-treated nickel-based solder alloy, it is quickly quenched in i...

Embodiment 2

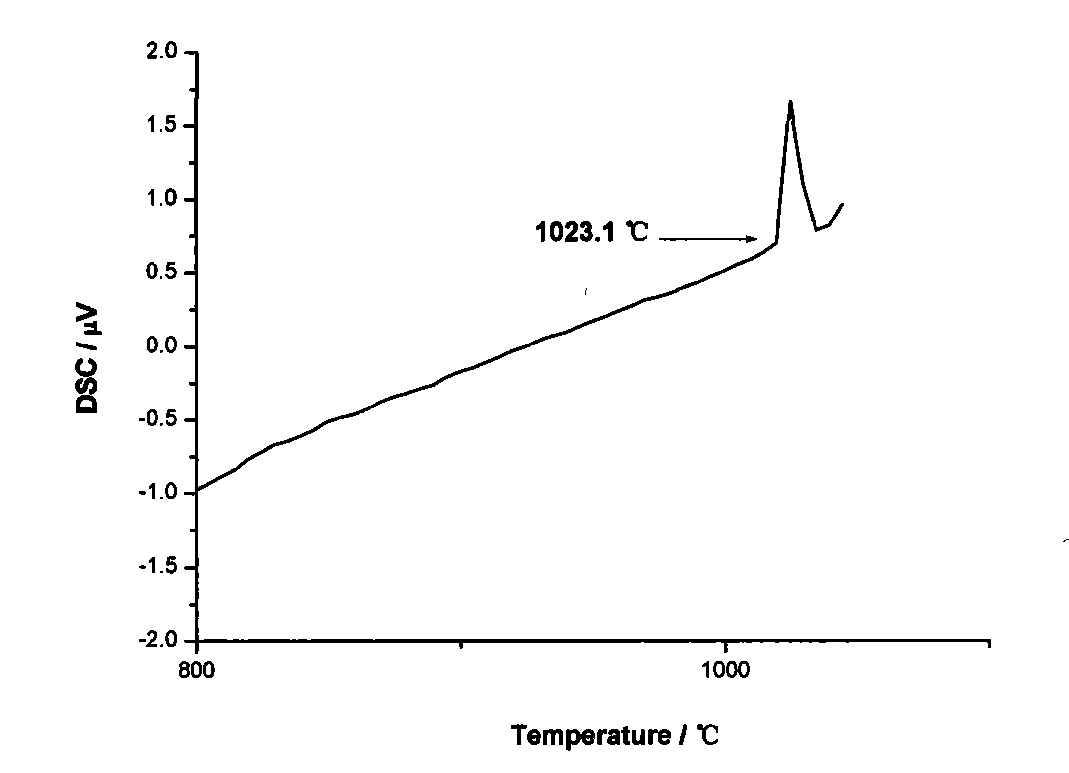

[0027] Embodiment 2: Preparation of Ni51.1Cr3Si2Zr14.1Sn30 solder alloy

[0028] Weigh 51.1% nickel with a purity of 99.9%, 3% chromium with a purity of 99.9%, 2% silicon with a purity of 99.9%, 14.1% zirconium with a purity of 99.9%, and 30% tin with a purity of 99.9%. After cleaning and weighing the above-mentioned chromium, silicon, zirconium, tin and nickel raw materials, they are alloyed by arc melting method under an inert gas protective atmosphere. The obtained button-shaped sample is preliminarily cut into strips and packed into a quartz tube to ensure that the vacuum in the quartz tube is below 1Pa, and then filled with high-purity argon to (0.7-0.8)×10 5Pa. The packaged sample is put into a reaction furnace for stress relief annealing heat treatment at a temperature of 750° C. for 7 days to obtain the nickel-based boron-free medium-temperature solder alloy. After taking out the above-mentioned heat-treated nickel-based solder alloy, it is quickly quenched in ice wa...

Embodiment 3

[0033] Embodiment 3: Preparation of Ni58Si2.8Zr13.2Sn25.9 solder alloy

[0034] 58% of nickel with a purity of 99.9%, 2.8% of silicon with a purity of 99.9%, 13.2% of zirconium with a purity of 99.9%, and 25.9% of tin with a purity of 99.9% were weighed. After cleaning and weighing the above-mentioned chromium, silicon, zirconium, tin and nickel raw materials, they are alloyed by arc melting method under an inert gas protective atmosphere. The obtained button-shaped sample is preliminarily cut into strips and packed into a quartz tube to ensure that the vacuum in the quartz tube is below 1Pa, and then filled with high-purity argon to (0.7-0.8)×10 5 Pa. The packaged sample is put into a reaction furnace for stress relief annealing heat treatment at a temperature of 900° C. for 5 days to obtain the nickel-based boron-free medium-temperature solder alloy. After taking out the above-mentioned heat-treated nickel-based solder alloy, it is quickly quenched in ice water, cut into c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com