Method for preparing inorganic thin-film transistor by complete solution treatment process

An inorganic thin film and triode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as good TFT performance, and achieve the effects of reducing production costs, simple process, and speeding up production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

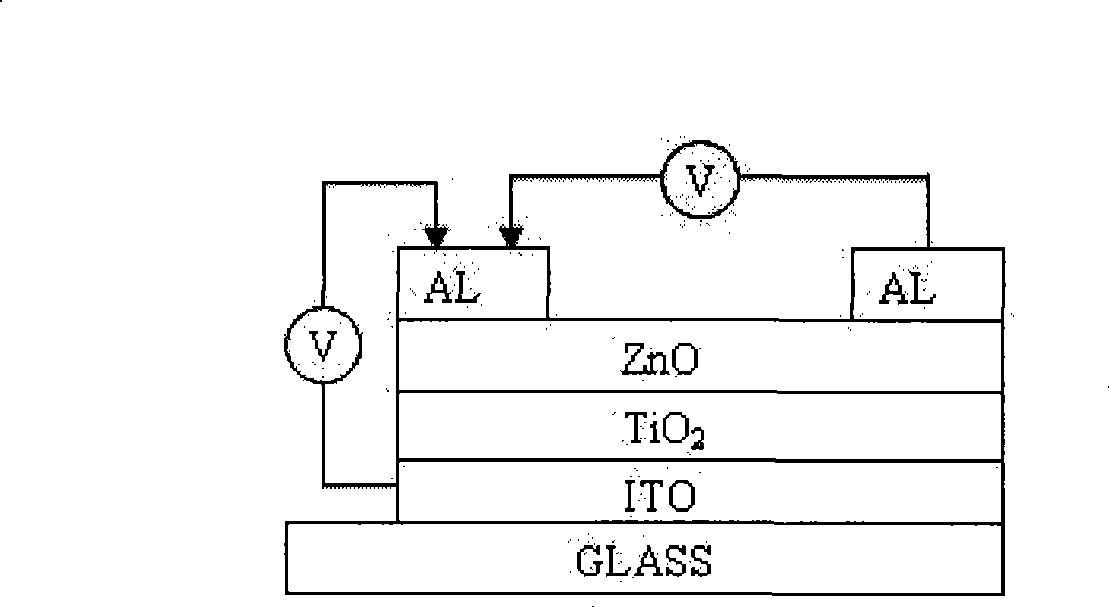

[0016] Embodiment 1: the preparation of a thin film triode with a bottom gate structure using ITO as the gate (gate), see figure 1 :

[0017] 1. TiO 2 Solution preparation: ①Use a pipette to measure 400ul of hydrochloric acid and dissolve in 200ml of ethanol; ②Add 55ml of tetrabutyl titanate and 200ml of ethanol to dissolve; ③Continue to add 5ml of acetylacetone and 11ml of deionized water. The above solutions are uniformly stirred while adding, the solvent is added completely, and the stirring is finished. TiO with a concentration of 0.33 was obtained 2 solution.

[0018] 2. Preparation of ZnO solution: ①Weigh 0.628g of Zn(CH 3 COO) 2· 2H 2 O was dissolved in 250ml of ethanol, heated to reflux with an electric furnace until boiling. After 30 minutes, when the solution does not boil, transfer it into the Erlenmeyer flask; ② Add a certain amount of LiOH.H 2 O solid, shaken in an ultrasonic bath for 20 minutes to produce a colloid. A ZnO solution with a concentration of...

Embodiment 2

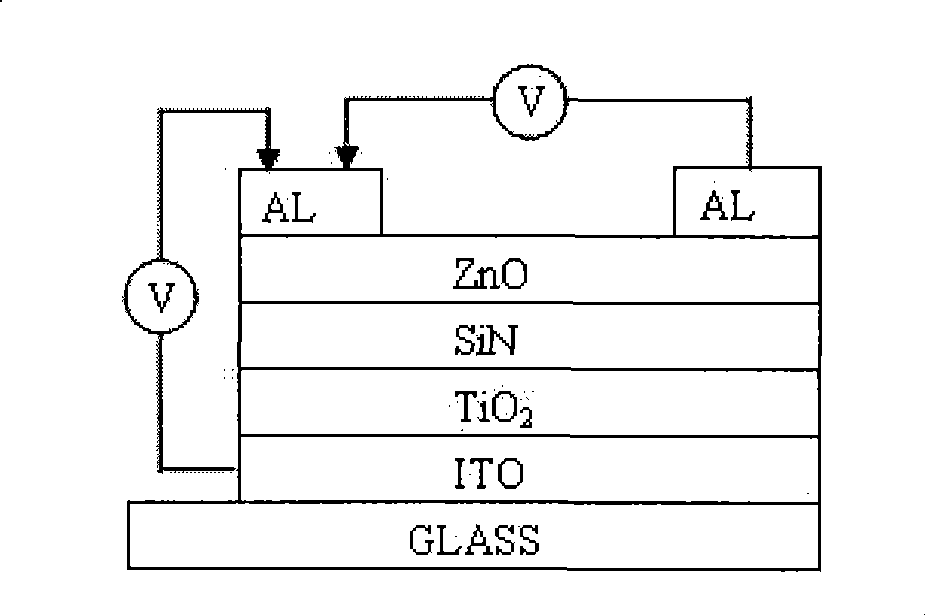

[0021] Embodiment two: use ITO as the preparation of the thin-film transistor of the bottom gate structure of gate (gate), see figure 2 , the specific steps are:

[0022] 1. TiO 2 Solution preparation: ①Use a pipette to measure 400ul of hydrochloric acid and dissolve in 200ml of ethanol; ②Add 27.5ml of tetrabutyl titanate and 200ml of ethanol to dissolve; ③Continue to add 5ml of acetylacetone and 11ml of deionized water. The above solutions are uniformly stirred while adding, the solvent is added completely, and the stirring is finished. TiO with a concentration of 0.165mol / L was obtained 2 solution.

[0023] 2. Preparation of ZnO solution: ①Weigh 0.319g of Zn(CH 3 COO) 2· 2H 2 O was dissolved in 250ml of ethanol, heated to reflux with an electric furnace until boiling. After 30 minutes, the solution was cooled to room temperature and transferred into the Erlenmeyer flask; ② At the same time, a certain amount of LiOH.H 2 O was added to another Erlenmeyer flask, then p...

Embodiment 3

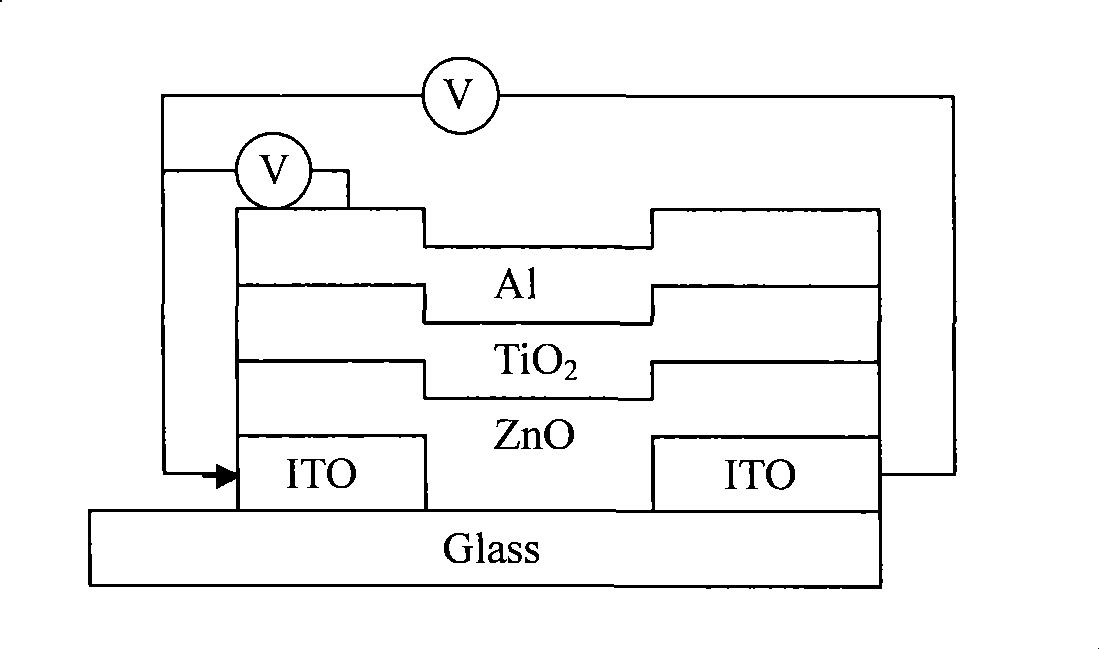

[0025] Example 3: Preparation of top gate structure thin film triode, see image 3 , the specific steps are:

[0026] 1. TiO 2 Solution preparation: ①Use a pipette to measure 400ul of hydrochloric acid and dissolve in 200ml of ethanol; ②Add 18.3ml of tetrabutyl titanate and 200ml of ethanol to dissolve; ③Continue to add 5ml of acetylacetone and 11ml of deionized water. The above solutions are uniformly stirred while adding, the solvent is added completely, and the stirring is finished. A TiO2 solution with a concentration of 0.11 mol / L was obtained.

[0027] 2. Preparation of ZnO solution: ①Weigh 0.511g of Zn(CH 3 COO) 2· 2H 2 O is dissolved in sufficient isopropanol. ② Add ethanolamine which is equimolar to zinc acetate, and under the action of catalyst glacial acetic acid, fully stir in a water bath at 60°C to obtain a colloid. A ZnO solution with a concentration of 0.04mol / L was obtained.

[0028] 3. Use ITO as the source and drain, and metal as the gate. Its channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com