Silver copper composite oxide film material for photoelectric semiconductor

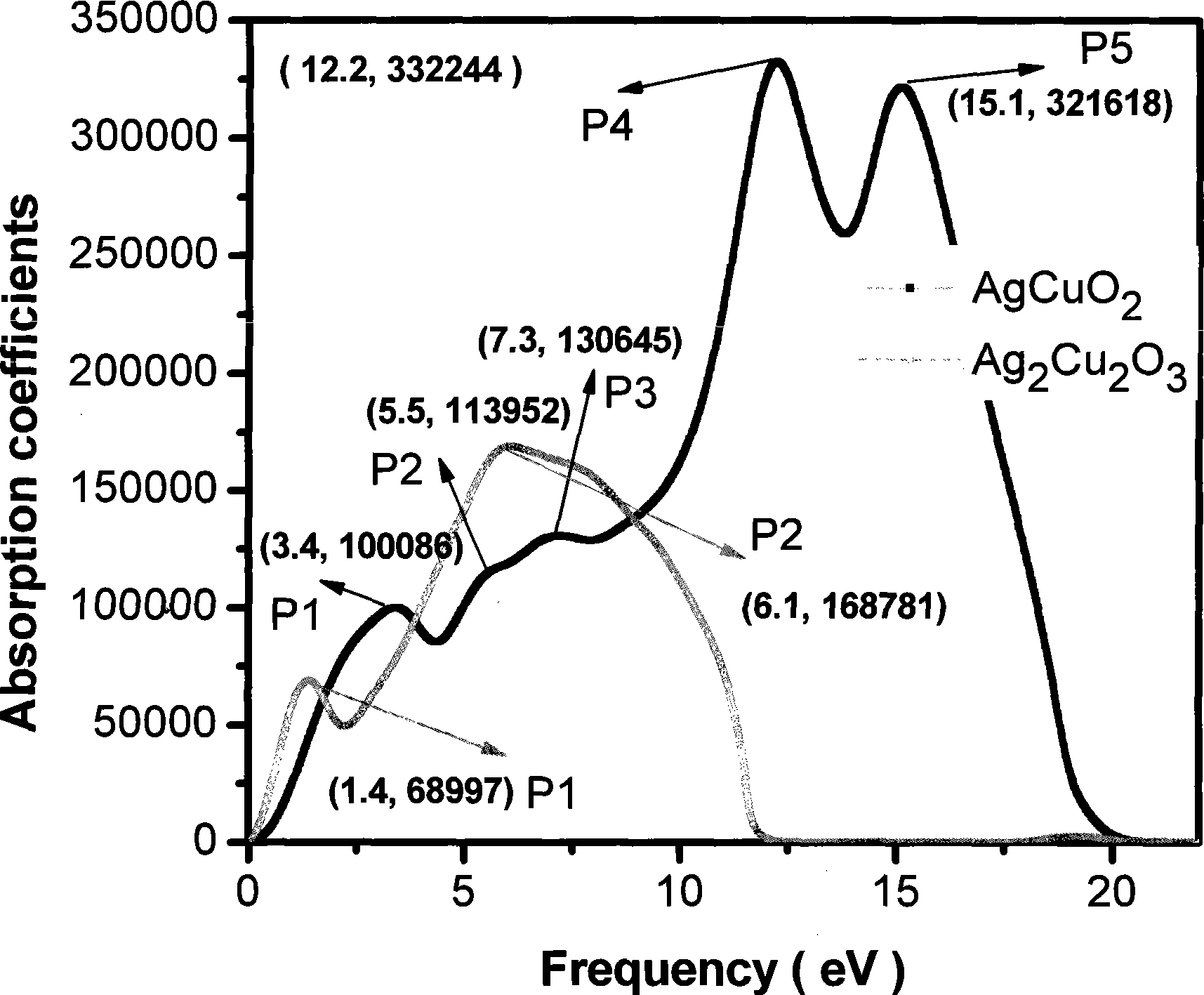

A composite oxide and optoelectronic semiconductor technology, which is applied in the direction of silver compounds, silver compounds, semiconductor devices, etc., can solve the problems of inability to absorb solar photons, low light absorption coefficient, low energy utilization rate, etc., and achieve good comprehensive performance and excellent preparation process Simplicity, the effect of reducing the use of scarce elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

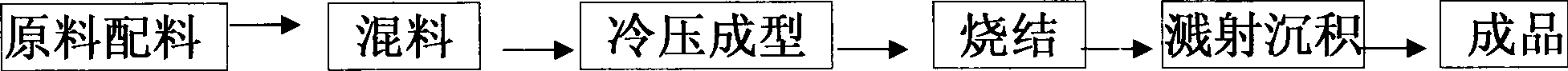

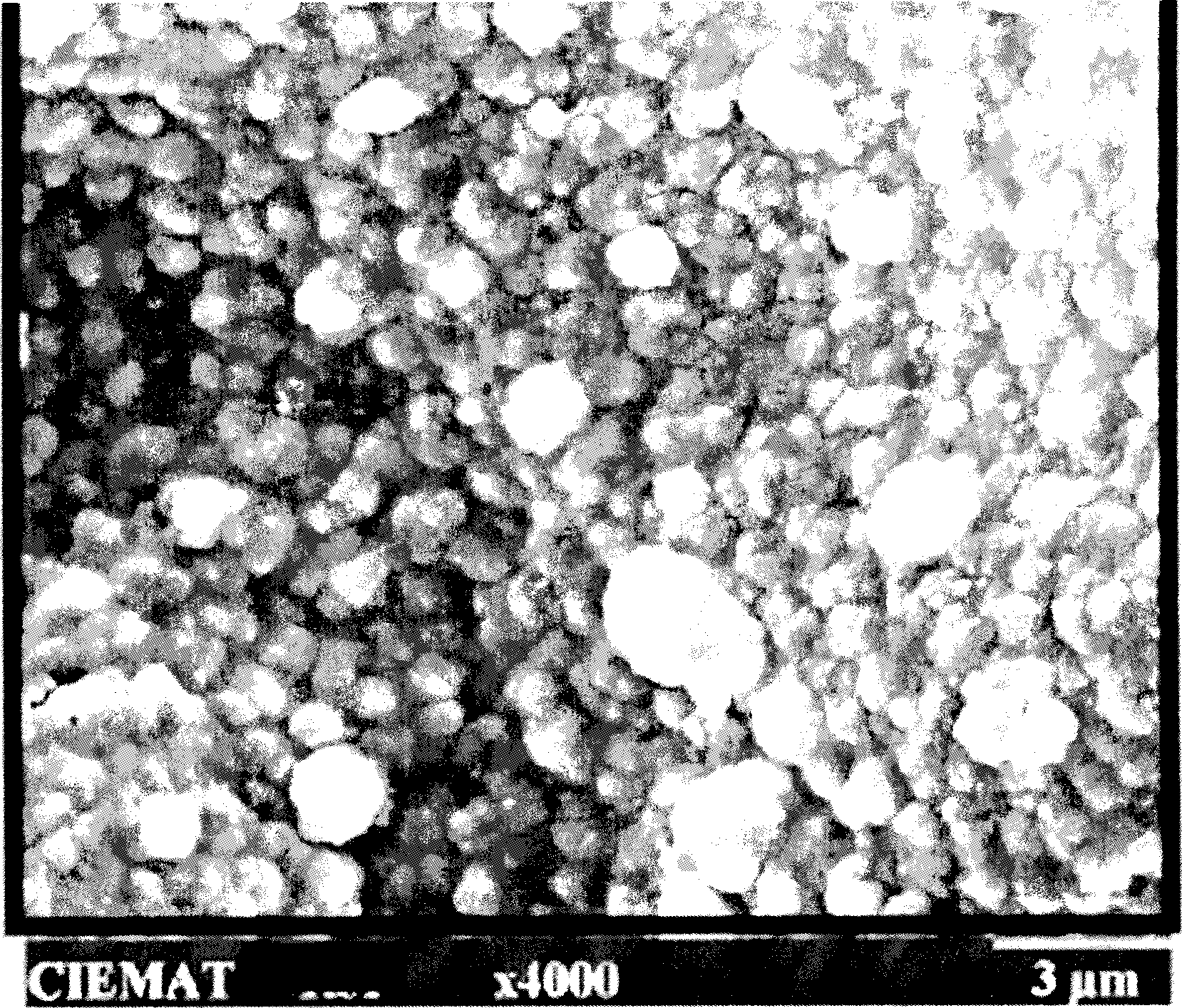

[0045] Press 38% copper powder (percentage by weight), 62% silver powder (percentage by weight), after mixing for 4 hours, bidirectionally press in a steel mold to form a biscuit, and the molding pressure of the biscuit is 650MPa; The ingot was sintered in an oxygen-containing atmosphere for 3 hours; the ingot was sputtered and deposited on a glass substrate for about 30 minutes, and further oxidized to obtain a silver-copper composite oxide (AgCuO 2 and a small amount of AgCuO 3 )film.

Embodiment 2

[0047] Prepare raw materials according to the ratio of 39% copper powder (weight percentage), 60.2% silver powder (weight percentage), cobalt powder (Co) 0.8% (weight percentage), after mixing for 6 hours, two-way pressing in the steel mold becomes plain Blank, the forming pressure of the blank is 450MPa; the blank is further pressed by 300MPa cold isostatic pressing, and the blank is sintered at 700°C for 4 hours in an oxygen-containing atmosphere to form an ingot, and the ingot is deposited on a glass substrate by sputtering, and the time is about 50 minutes, and through further oxidation treatment, obtain the cobalt-doped silver-copper composite oxide (AgCuO 2 and a small amount of AgCuO 3 )film.

Embodiment 3

[0049] According to 98.6% of the silver-copper alloy powder (wherein the weight percent content of copper is 37% of the silver-copper alloy powder), 0.7% Zn (zinc), 0.5% Mn (manganese) and 0.4% In (indium) of the alloy powder weight are added Add elements, prepare raw materials in proportion, after 8 hours of mixing, cold isostatic pressing is formed into a green body, the green body forming pressure is 250MPa; Sputtering deposition on the bottom, the time is about 60 minutes, and after further oxidation treatment, a zinc-manganese-indium-doped silver-copper composite oxide (AgCuO 2 and a small amount of AgCuO 3 )film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com