Method for preparing microencapsulated ammonium polyphosphate

An ammonium polyphosphate and microcapsule technology is applied in the field of preparation of ammonium polyphosphate encapsulated by microcapsules. The effect of particle size averaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

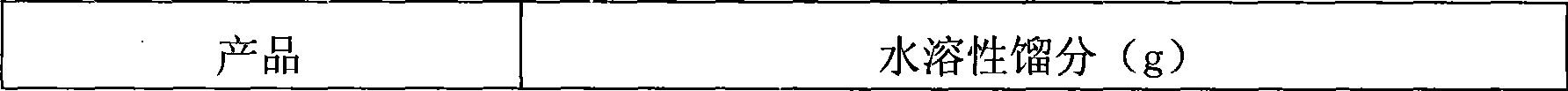

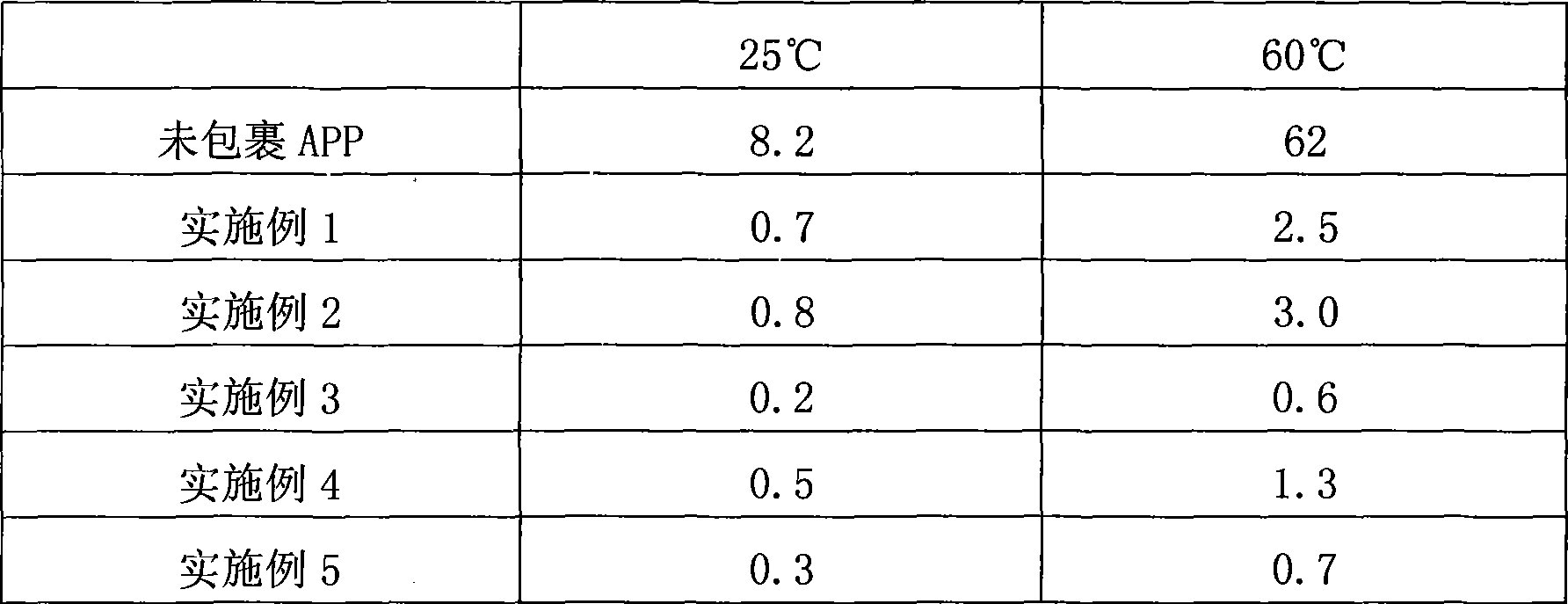

Embodiment 1

[0027] In a 2L reaction kettle with a stirring and reflux device, add 200g of APP and suspend it in 350ml of absolute ethanol, then add 8g of bisphenol A epoxy resin E51 dropwise, heat the suspension to a slight boil, continue stirring to disperse APP and E51 for 30min , add dropwise the alcohol solution of 2.45g polyetheramine (2.45g polyetheramine is dissolved in 50ml dehydrated alcohol) in 30min, under the microboiling condition of dehydrated alcohol, stir, react 3 hours, make epoxy resin solidify, Then filter, and further solidify and dry the filtered product at 100° C. under a nitrogen atmosphere to obtain 206.34 g of encapsulated APP with excellent morphology and fluidity.

Embodiment 2

[0029] In a 1L reaction kettle with a stirring and reflux device, add 100g of APP and suspend it in 300ml of anhydrous acetone, then add 5g of bisphenol A epoxy resin E44 dropwise, heat the suspension to a slight boil, continue stirring to disperse APP and E44 for 30min 1.15g polyetheramine alcohol solution (1.15g polyetheramine dissolved in 25ml anhydrous acetone) was added dropwise within 30min, stirred and reacted for 6 hours under anhydrous acetone microboiling conditions, to cure the epoxy resin , and then filtered, and further solidified and dried the filtered product at 100° C. under a nitrogen atmosphere to obtain 105.18 g of encapsulated APP with excellent morphology and fluidity.

Embodiment 3

[0031] In a 2L reaction kettle with a stirring and reflux device, add 200g of APP and suspend it in 500ml of anhydrous methanol, then add 6.5g of bisphenol A epoxy resin E51 dropwise, heat the suspension to a slight boil, and continue stirring to disperse APP and E51 30min, dropwise the alcoholic solution of 3.25g KH550 (3.25g KH550 is dissolved in 50ml anhydrous methanol) in 30min, under anhydrous methanol slight boiling condition, stir, react about 8 hours, epoxy resin is solidified, then Filtration, further solidification and drying of the filtered product at 120° C. under a nitrogen atmosphere, obtained 207.33 g of encapsulated APP with excellent morphology and fluidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com