Method of fabrication of a finfet element

A fin field effect and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low ion energy and inability to meet the performance of fin field effect transistors, and meet the performance requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The manner in which the various embodiments can be made and used are described in detail below. However, it is worth noting that the various applicable inventive concepts provided by the present invention can be implemented according to various changes in the specific content, and the specific embodiments discussed here are only used to show the specific use and manufacture of the present invention method without limiting the scope of the present invention.

[0052] The manufacturing process of the preferred embodiment of the present invention is illustrated below through various drawings and examples. In addition, the same symbols represent the same or similar elements in various different embodiments and drawings of the present invention.

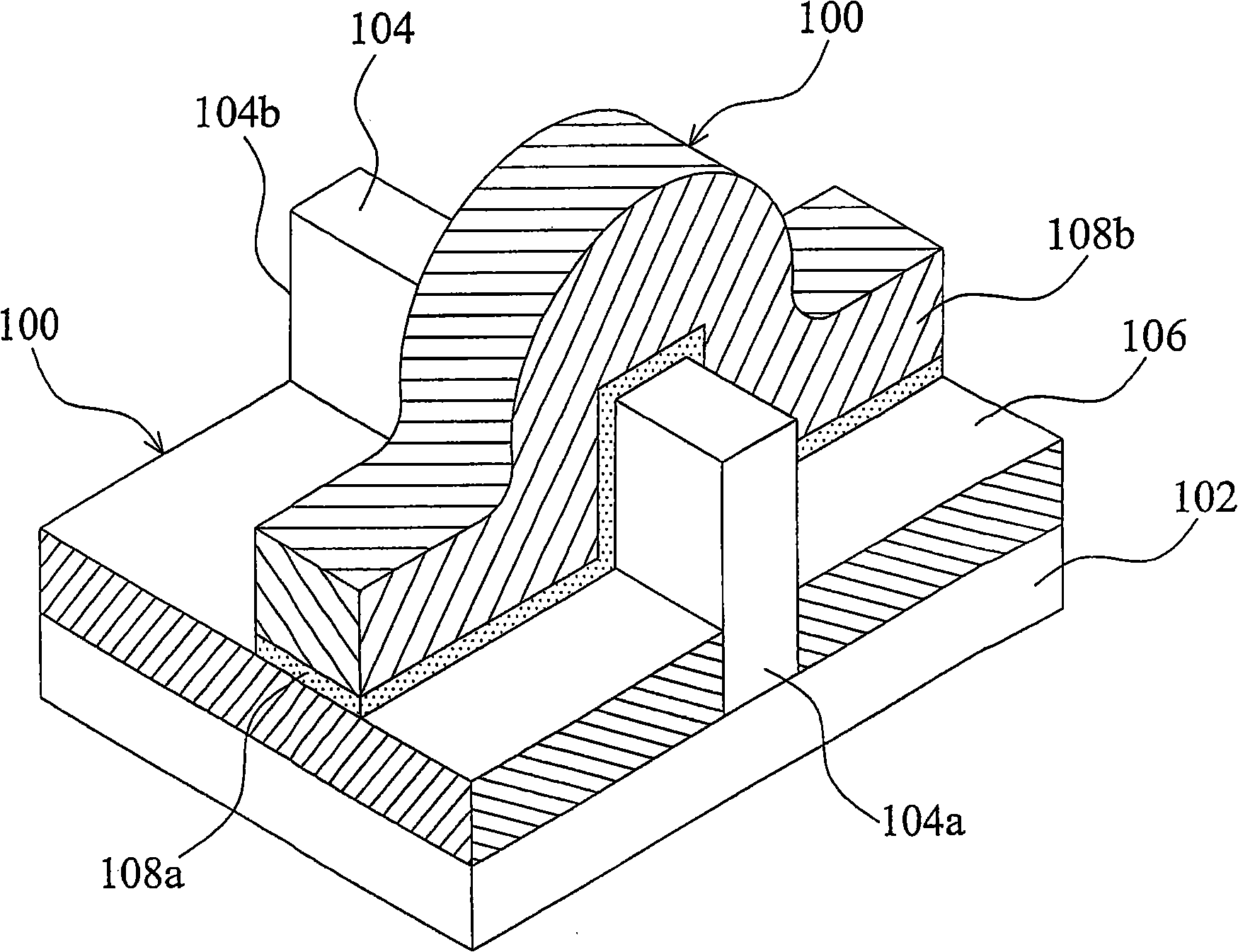

[0053] figure 1 An embodiment of a FinFET device 100 is shown. The FinFET device 100 includes a substrate 102 , an insulating layer 106 , a fin 104 , and a gate structure 108 . In an embodiment, substrate 102 includes a silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com