Wired circuit board and producing method thereof

A technology for wiring circuit substrates and coating layers, which is applied in the manufacture of printed circuits, printed circuits, printed circuit components, etc., can solve problems such as short circuit of conductor patterns, prevent ion migration, prevent discoloration, improve connectivity and connection durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

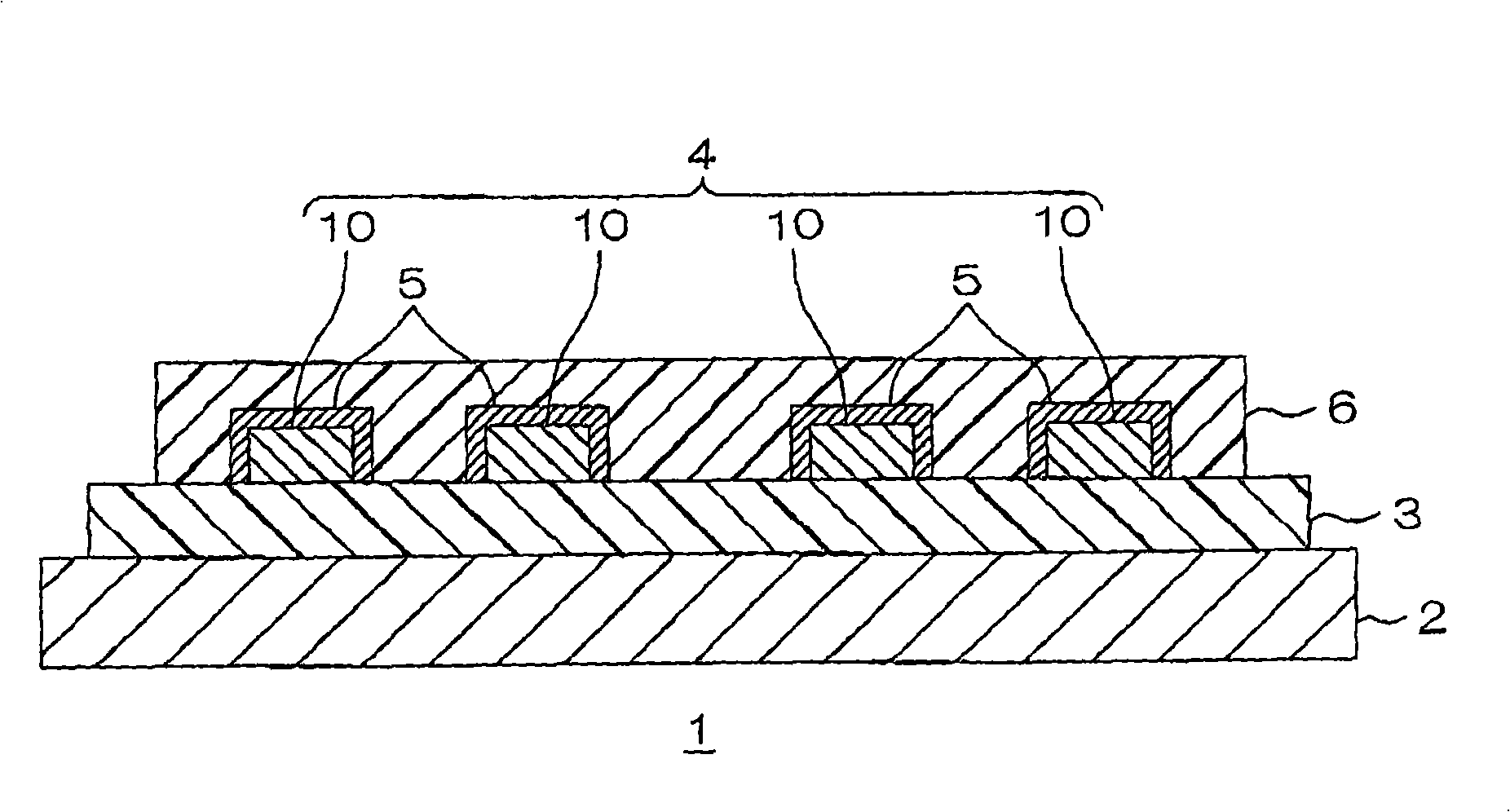

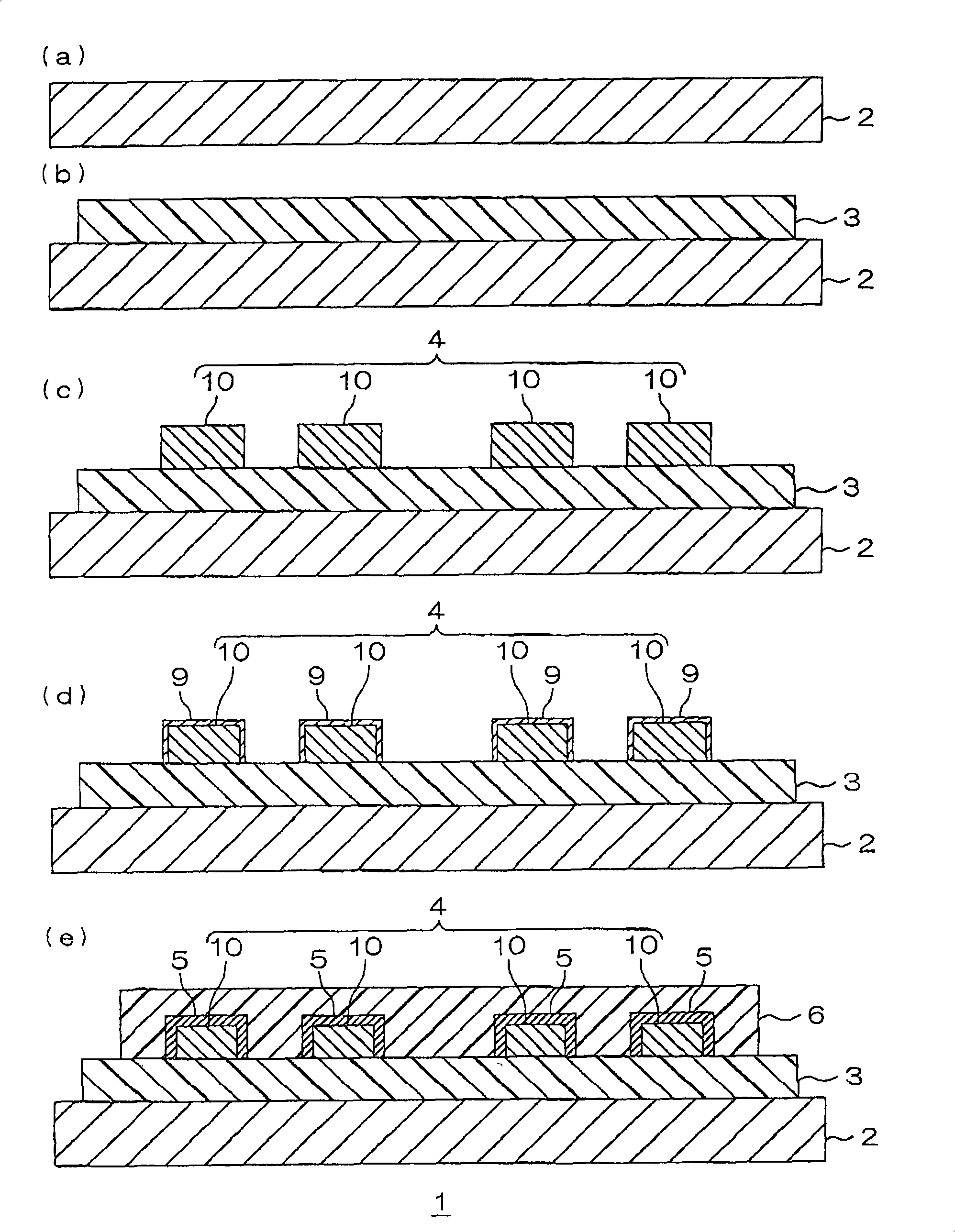

[0065] First, prepare a metal support substrate made of stainless steel with a thickness of 25 μm (see image 3 (a)) Furthermore, the varnish of the photosensitive polyamic-acid resin was apply|coated to the whole surface of a metal supporting board|substrate, and it heated at 90 degreeC for 15 minutes, and it dried. Then, after exposure and development, it was cured (imidized) by heating at 370° C. for 120 minutes under reduced pressure to form an insulating base layer with a thickness of 10 μm (see image 3 (b)).

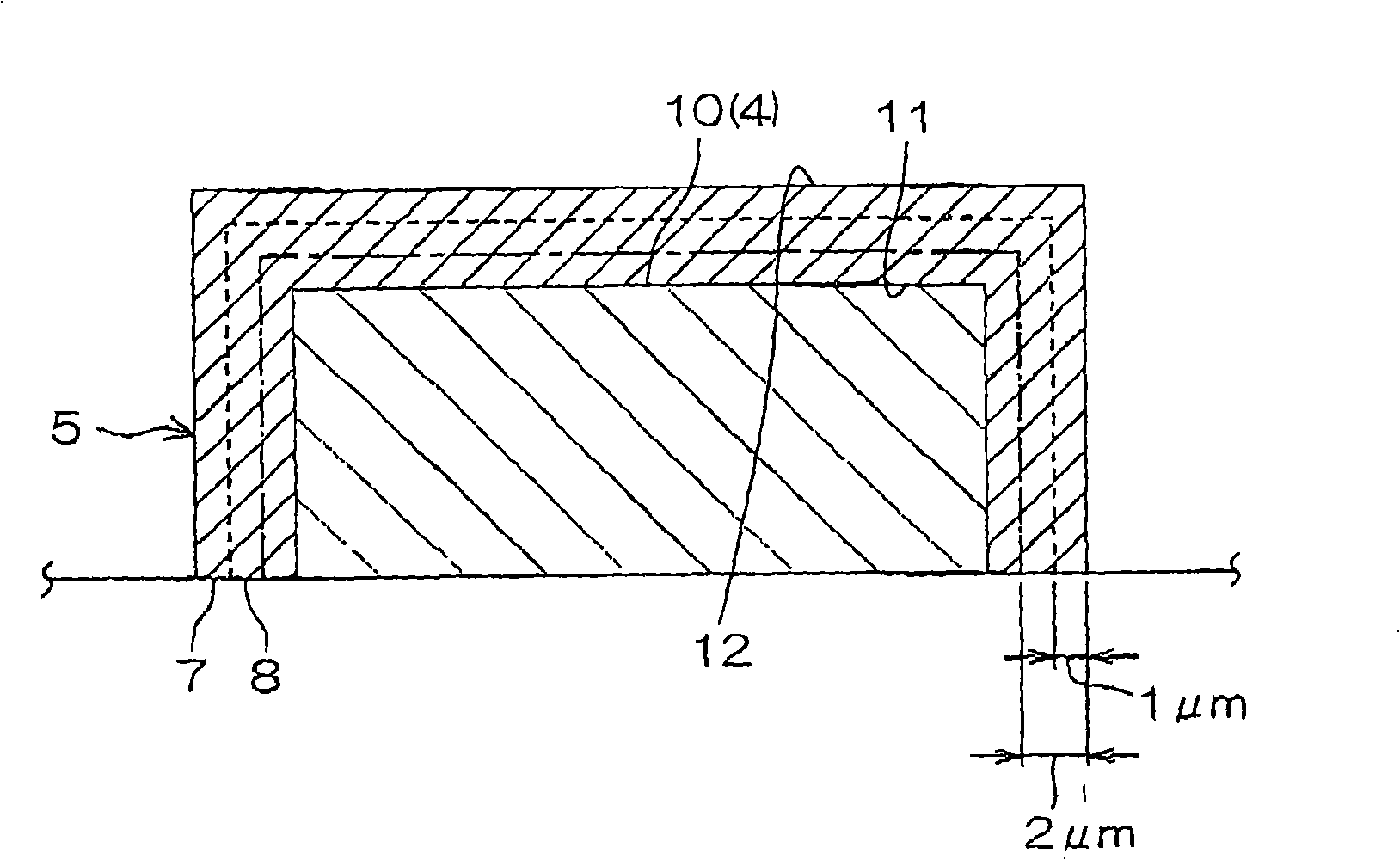

[0066] Next, a seed film was formed by sequentially forming a chromium thin film with a thickness of 50 nm and a copper thin film with a thickness of 100 nm by sputtering. Then, after forming the plating protective layer of the pattern opposite to the conductor pattern on the upper surface of this kind of film, a conductor pattern formed of copper with a thickness of 10 μm is formed by electrolytic copper plating (refer to image 3 (c)). In addition, the width ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com