Method of preparing composite membrane for gasoline desulphurization

A manufacturing method and composite membrane technology, which can be used in refining by dialysis, chemical instruments and methods, membrane technology, etc., and can solve problems such as high consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ①. Preparation method of support membrane:

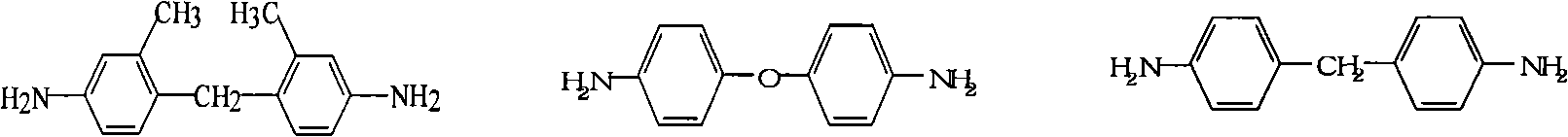

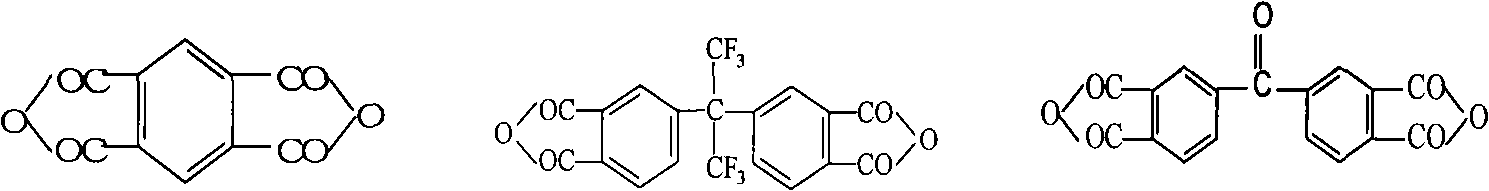

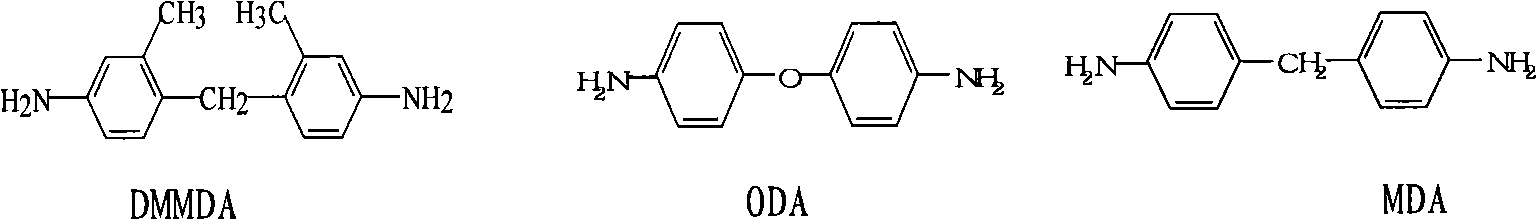

[0024] Dissolve 4.95g (0.025mol) of diphenylmethanediamine (MDA) in 80mL of N,N-dimethylacetamide, stir electromagnetically, and add 5.45g (0.025mol) in batches to the solution under nitrogen protection Pyromellitic dianhydride (PMDA), stirred and reacted at room temperature for 8 hours to obtain a polyamic acid solution. Add 6 mL of acetic anhydride and 9 mL of triethylamine under rapid stirring, and stir at room temperature for 6 hours to complete partial imidization. The reaction solution is precipitated in water to obtain a light yellow product, which is washed with water and dried at 50°C to constant weight. Take 10g of the dried polyimide synthesized above, and dissolve it in a mixed solvent of 20mL N, N-dimethylacetamide and 16mL acetone with electromagnetic stirring at room temperature, add 2.2g polyvinylpyrrolidone additive, and dissolve evenly. After filtering with a 300-mesh stainless steel mesh, the filtrate was...

Embodiment 2

[0030] ① Preparation method of support membrane:

[0031] 5.658g (0.025mol) of 3,3'dimethyldiphenylmethanediamine (DMMDA) was dissolved in 80-mL of dimethylformamide, magnetically stirred, and 11.106g ( 0.025mol) of hexafluorodianhydride (6FDA), stirred and reacted at room temperature for 8 hours to obtain a polyamic acid solution with a concentration of 17.32wt%. Add 6 mL of acetic anhydride and 9 mL of triethylamine under rapid stirring, and stir at room temperature 6 Partial imidization was completed within 2 hours, and the reaction solution was precipitated in water to obtain a pale yellow product, which was washed with water and dried at 50°C to constant weight. Take 10g of the dried polyimide synthesized above, and dissolve it in a mixed solvent of 20mL N, N-dimethylacetamide and 16mL acetone with electromagnetic stirring at room temperature, add 2.7g polyethylene glycol additive, and dissolve evenly , after filtering with a 300-mesh stainless steel mesh, the filtrate ...

Embodiment 3

[0037] ① Preparation method of support membrane:

[0038] 5g (0.025mol) of 4,4'-diaminodiphenyl ether (ODA) was dissolved in 80-mL of dimethyl sulfoxide, magnetically stirred, and 8.0558g (0.025mol) was added in batches to the solution under nitrogen protection Benzophenone tetra-acid dianhydride (BTDA) was stirred and reacted at room temperature for 8 hours to obtain a polyamic acid solution, and the concentration of this solution was 14.03 wt%. Add 6 mL of acetic anhydride and 9 mL of triethylamine under rapid stirring, and stir at room temperature 6 Partial imidization was completed within 2 hours, and the reaction solution was precipitated in water to obtain a pale yellow product, which was washed with water and dried at 50°C to constant weight. Take 10 g of the dried polyimide synthesized above, and dissolve it in a mixed solvent of 20 mL of N, N-dimethylacetamide and 16 mL of acetone under electromagnetic stirring at room temperature, add 1.6 g of polyvinyl alcohol addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com