Complete biodegradable polylactic acid composite material and method for preparing same

A composite material and biodegradable technology, which is applied in the field of fully biodegradable polylactic acid composite materials and their preparation, can solve the problems of lengthy melt blending and granulation production processes, industrial production, and performance degradation, and achieve mechanical properties. The effect of reducing raw material cost and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

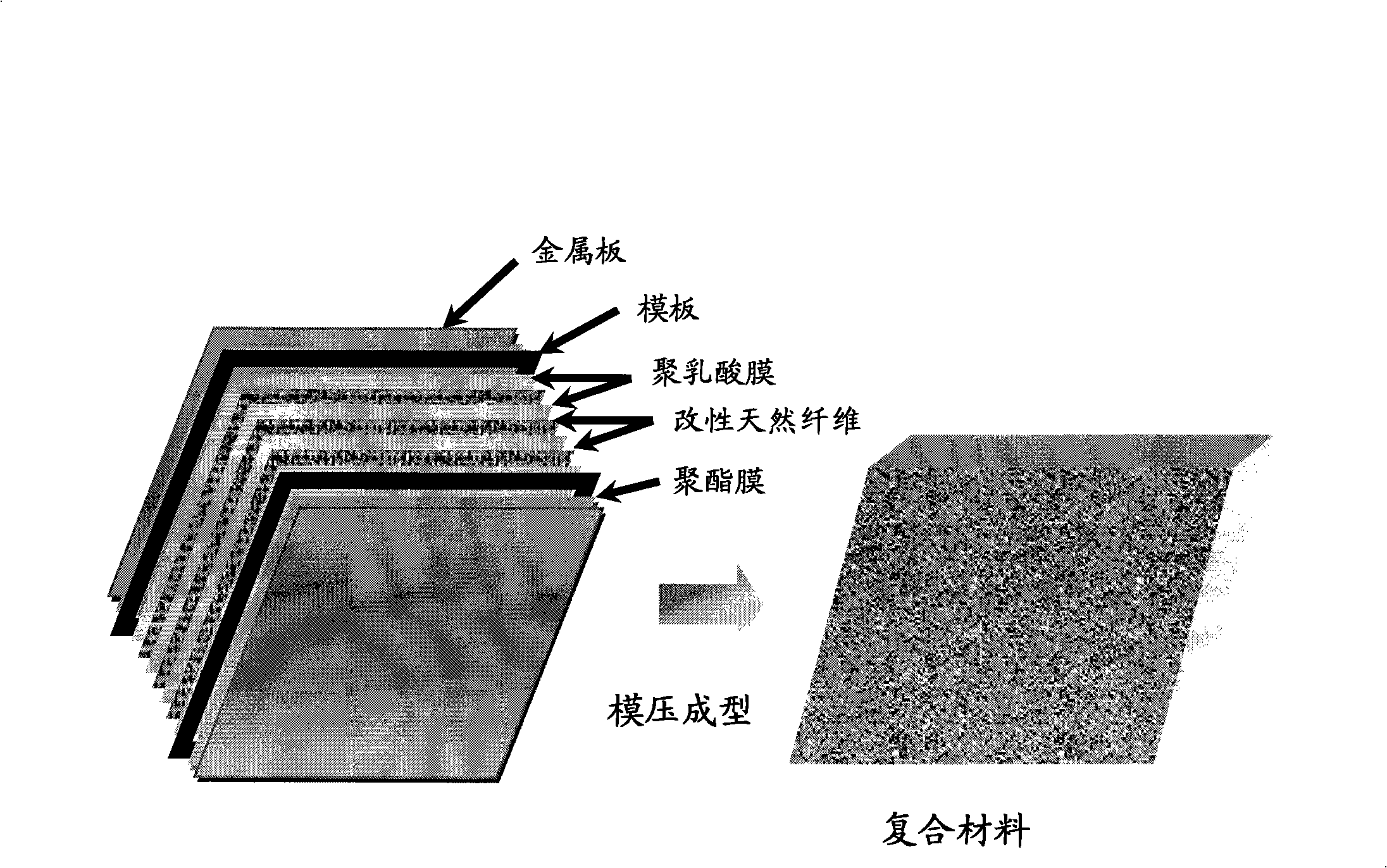

Method used

Image

Examples

Embodiment 1

[0029] 1. Take 15g of ramie fiber with an aspect ratio of 15, soak it in 300g concentration of 0.01% silane coupling agent γ-aminopropyltriethylsiloxane (KH-550) aqueous solution for 1 minute, take it out, °C for 1 hour to obtain surface-treated ramie fibers.

[0030] 2. Put 8g of polylactic acid into a mold with a thickness of 0.3mm, and mold it in a flat vulcanizing machine. The molding temperature is 150°C, the time is 1 minute, and the pressure is 5Mpa to prepare a polylactic acid sheet with a thickness of 0.3mm.

[0031] 3. Put the 2 polylactic acid templates obtained in step 2 into a mold with a thickness of 0.6 mm, and spread 6 g of surface-modified ramie fibers in step 1 between the polylactic acid sheets. Then press molding in a flat vulcanizer, the molding temperature is 150° C., the time is 1 minute, and the pressure is 5 MPa to obtain the ramie fiber / polylactic acid composite material.

Embodiment 2

[0033] 1. Get 40g of sisal fiber with an aspect ratio of 50, soak it in a 400g concentration of 2% silane coupling agent γ-glycidyl ether propyltrimethoxysilane (KH-560) aqueous solution for 30 minutes, take it out, and Dry at 100° C. for 2 hours to obtain surface-treated sisal fibers.

[0034] 2. Put 15g of polylactic acid into a mold with a thickness of 2mm, and mold it in a flat vulcanizing machine. The molding temperature is 160°C, the time is 3 minutes, and the pressure is 10Mpa to obtain a polylactic acid sheet with a thickness of 2mm.

[0035] 3. Put the 3 polylactic acid templates obtained in step 2 into a mold with a thickness of 6 mm, and evenly spread 20 g of surface-modified sisal fibers in step 1 between the polylactic acid sheets. Then press molding in a flat vulcanizer, the molding temperature is 160° C., the time is 5 minutes, and the pressure is 10 MPa to obtain the sisal fiber / polylactic acid composite material.

Embodiment 3

[0037] 1. Take 40g of jute fiber with an aspect ratio of 100, soak it in a 300g aqueous solution of 3% silane coupling agent vinyltriethoxysilane (A-151) for 100 minutes, take it out, and dry it at 120°C for 48 Hour, obtain the jute fiber that is through surface treatment.

[0038] 2. Put 30g of polylactic acid into a mold with a thickness of 4mm, and mold it in a flat vulcanizing machine. The molding temperature is 180°C, the time is 5 minutes, and the pressure is 20Mpa to obtain a polylactic acid sheet with a thickness of 4mm.

[0039] 3. Put 3 polylactic acid templates obtained in step 2 into a mold with a thickness of 12mm, and evenly spread 40g of surface-modified jute fibers in step 1 between the polylactic acid sheets. Then mold compression molding in a flat vulcanizer, the molding temperature is 180 DEG C, the time is 15 minutes, and the pressure is 30Mpa to obtain the jute fiber / polylactic acid composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com