Method for hydrogenation dialkene removal of catalytically cracked gasoline

A technology for catalytic cracking gasoline and diene removal, which is applied in the field of petroleum refining catalytic cracking gasoline hydrogenation and diene removal, and can solve the problem of low removal rate of diene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

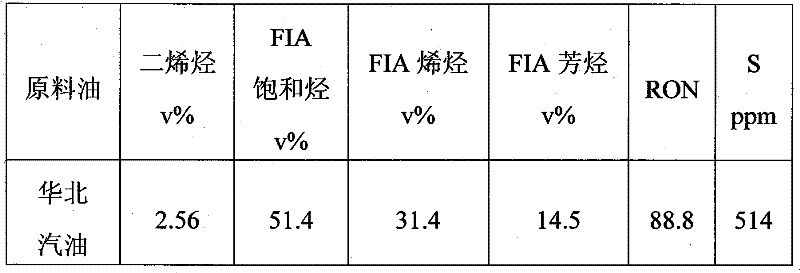

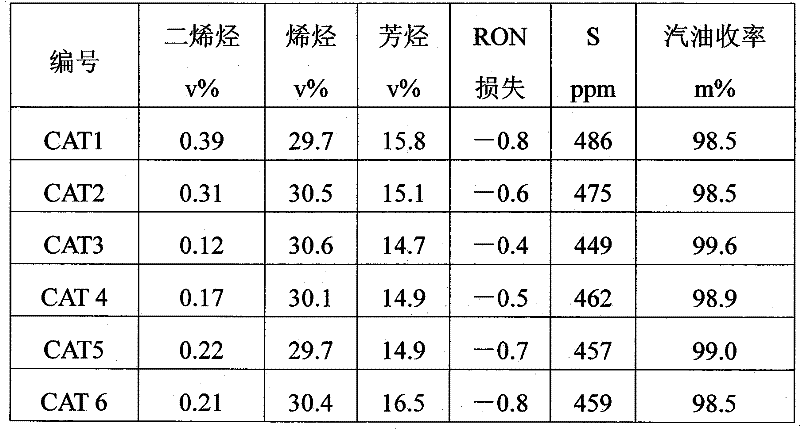

Examples

Embodiment 1

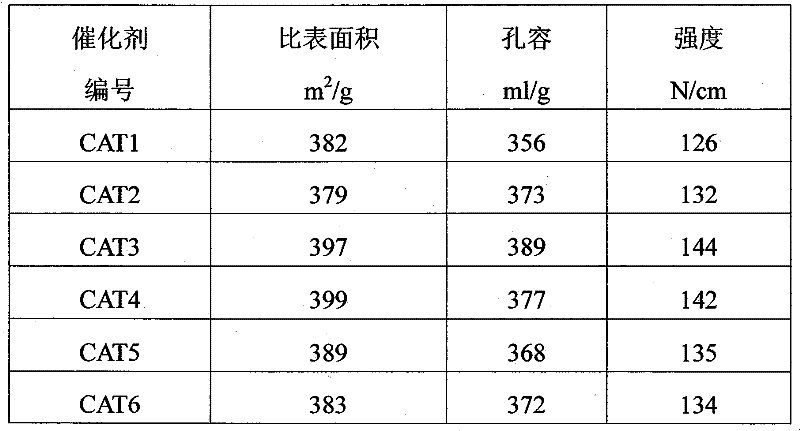

[0027] Take by weighing the Y molecular sieve (Na 2 (weight≤0.2%), 72gV250 powder, and they are ground and mixed evenly, add about 2ml concentration and be the dilute nitric acid solution of 2g / 100ml, stir into the jelly thing with suitable humidity, extrude into a circumscribed circle diameter of 1.6 on the extruder The clover-shaped strips of 1 mm were dried at 120° C. and calcined at 550° C. in an air atmosphere for 3 hours to obtain carrier ZT1.

[0028] Weigh 189.4 g (dry basis) of the carrier ZT prepared by the above method, and put it in an Erlenmeyer flask. After vacuuming the Erlenmeyer flask, use 100ml containing CoO2.4g, MoO 3 6.8g, MgO0.7g, NiO0.7g solution was sprayed slowly, and left to stand for 2 hours. Then, it was dried at 120° C. for 4 hours and calcined at 450° C. for 4 hours to obtain catalyst CAT1.

Embodiment 2

[0030] Weigh 189.4 g (dry basis) of the carrier ZT prepared in the above-mentioned Example 1, and put it into 200 ml of molybdenum, cobalt, nickel, and magnesium solutions for impregnation. The solution contains CoO2.4g, MoO 3 6.8g, MgO0.7g, NiO0.7g, impregnated at room temperature for 2 hours, then dried at 120°C for 4 hours, and calcined at 450°C for 4 hours to obtain catalyst CAT2.

Embodiment 3

[0032] Take by weighing the Y molecular sieve (Na 2 O weight≤0.2%), 72g V250 powder, 2g NH4 F, Grind and mix them evenly, add about 2ml of dilute nitric acid solution with a concentration of 2g / 100ml, stir it into a jelly with suitable humidity, extrude it into a clover-shaped strip with a circumcircle diameter of 1.6mm on the extruder, and bake it at 120°C dry, and calcined at 550° C. in an air atmosphere for 3 hours to obtain carrier ZT2.

[0033] Weigh 4.2 g (dry basis) of the carrier ZT28 prepared by the above method, and put it in a conical flask. After vacuuming the Erlenmeyer flask, use 3.5g of CoO, MoO 3 100ml of a solution of 10.2g, MgO1.0g, and NiO1.1g was slowly sprayed, and left to stand for 2 hours. Then, it was dried at 120° C. for 4 hours and calcined at 450° C. for 4 hours to obtain catalyst CAT3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com