Ultra-precision processing apparatus based on photon crystal material and imaging monitoring method

An ultra-precision machining and photonic crystal technology, which is applied in the fields of ultra-precision machining devices and machinery manufacturing, can solve the problems of complicated introduction of roughness devices and influence of roughness measurement, so as to achieve short polishing time, improve polishing effect, and improve The effect of polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

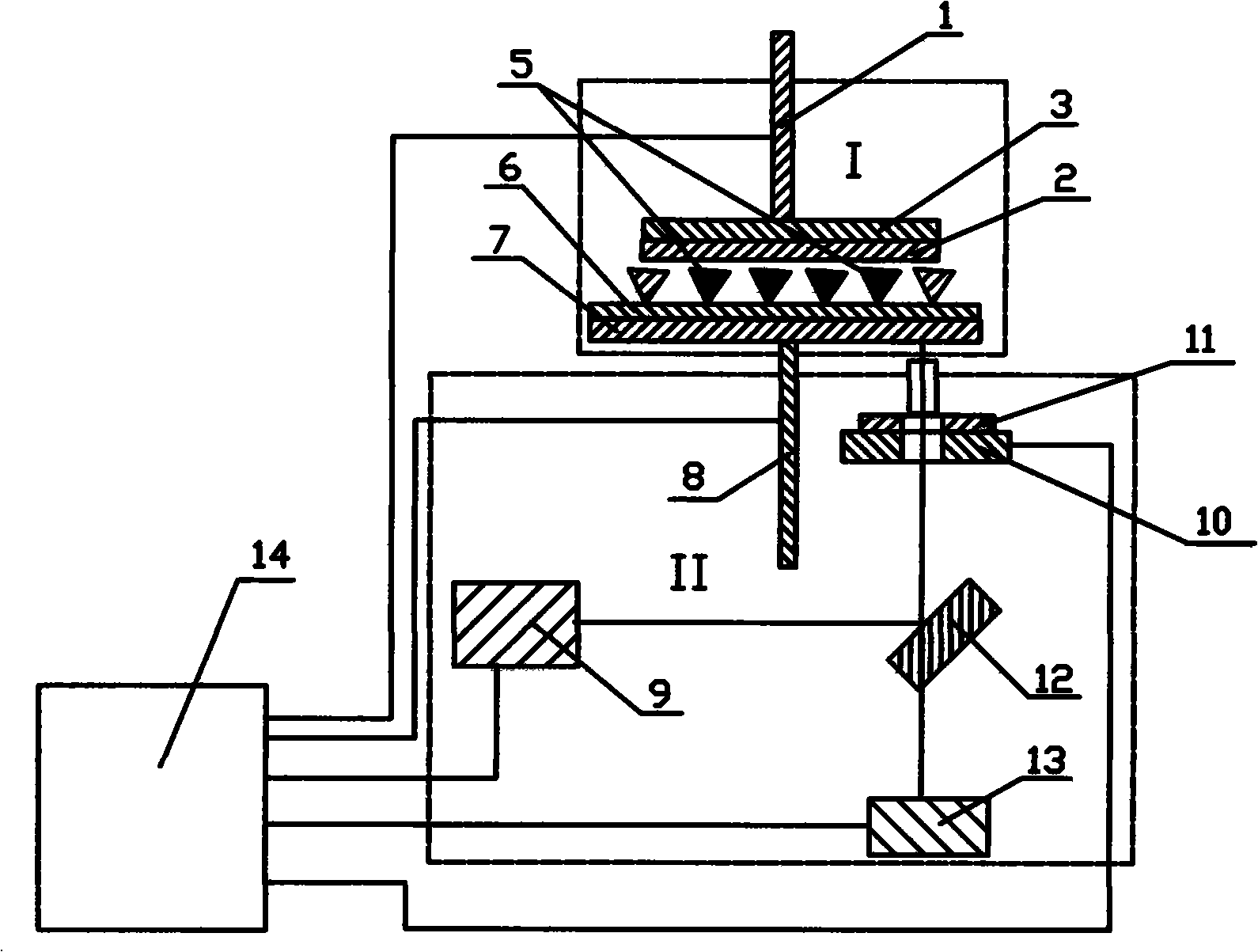

[0030] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing, as figure 1 As shown, the ultra-precision machining device of the present invention includes: the device includes two parts, a polishing hardware system I and a spectral detection system II, and the polishing hardware system I includes a polishing sheet support frame power system 1, a polishing sheet 2, a support fixture 3, Polishing shedding abrasive 5, substrate 6, substrate support frame 7, substrate support frame power system 8; the lower end of the polishing sheet support frame power system 1 is connected to the support fixture 3, and the lower end of the support fixture 3 is connected to the polishing sheet 2, and the polishing sheet 2 The lower end of the substrate 6 is correspondingly provided with a substrate 6, the lower end of the substrate 6 is connected to the substrate support frame 7, and the lower end of the substrate support frame 7 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com