Expanded carbon flame-proof polypropelene composition and preparation method thereof

A technology for flame-retardant polypropylene and its composition, which is applied in the field of intumescent charcoal flame-retardant polypropylene composition and its preparation. The production method is simple and reliable, the mechanical properties remain unchanged, and the flame retardant performance is excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

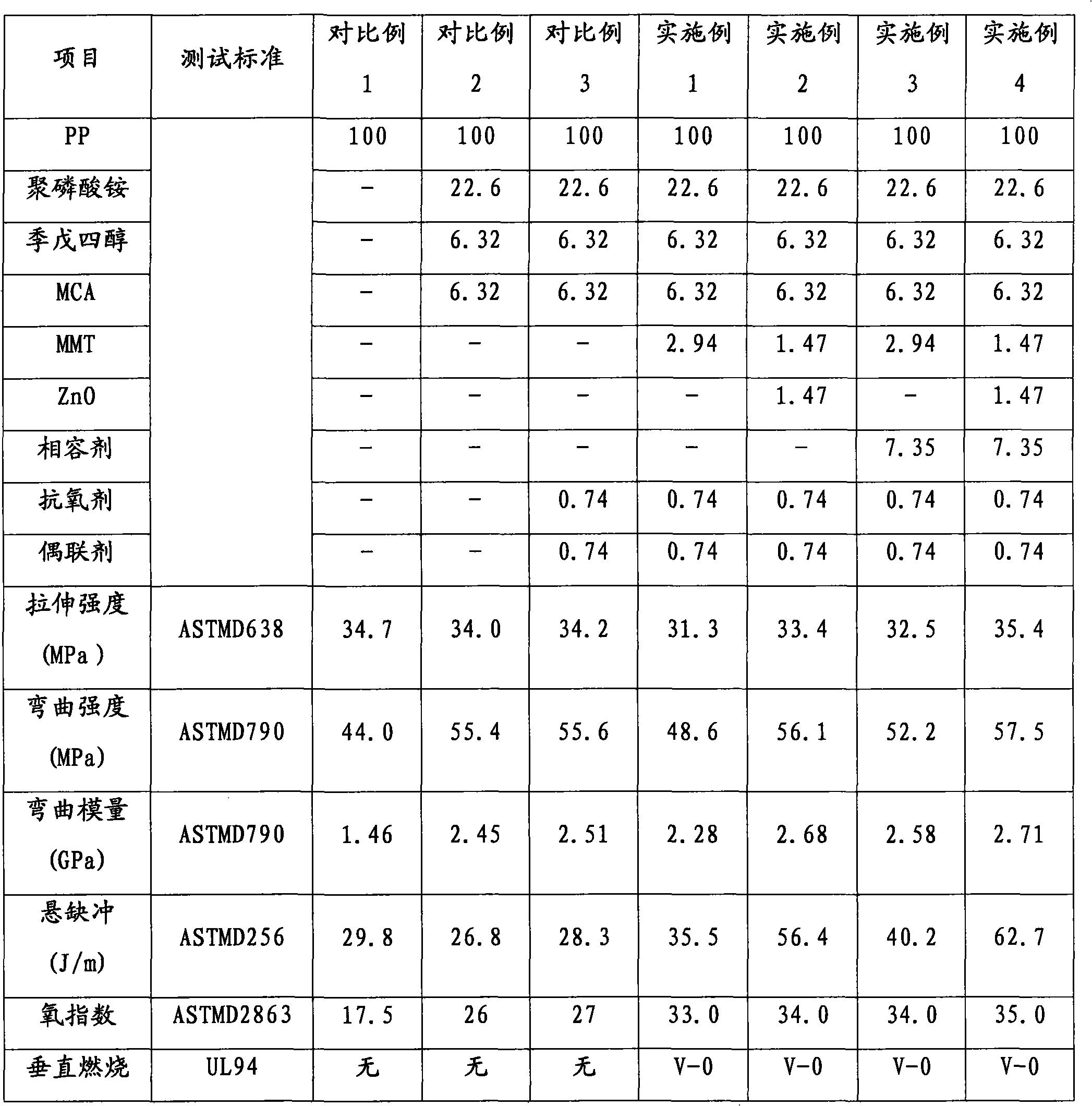

[0027] Polypropylene (4# powder, Zhonglan Tianjin Chemical Plant), compatibilizer maleic anhydride grafted polypropylene (g-PP, American EXXON company), ammonium polyphosphate (APP, Zhenjiang Star Flame Retardant Material Factory), Pentaerythritol (PER, Jilin Changsong Chemical Plant), melamine cyanurate (MCA, Zhonglan Chenguang Chemical Research Institute), montmorillonite (NanocorI.44P, American Naco Corporation), zinc oxide (ZnO, commercially available), Antioxidant B225 (Swiss Ciba Company), silane coupling agent (KH-550, Nanjing Shuguang Chemical Factory), put into a low-speed mixer and stir evenly, so that all components are fully mixed evenly. Then the above mixed material was extruded and granulated in a twin-screw extruder (TE-30, Nanjing Ruiya Company) at 180-200°C. The extruded pellets were dried in a constant temperature oven at 80°C for 6 hours, and then injected into standard specimens at a temperature of 190-210°C for various mechanical property tests. The spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com