Lanthanum chromite-doped film type thermocouple and preparation method thereof

A technology of lanthanum chromate thin film and thermocouple, which can be used in the manufacture/processing of thermoelectric devices, materials for lead-out wires of thermoelectric devices, and thermometers with electric/magnetic elements that are directly sensitive to heat, etc., which can solve the instability of high temperature measurement , the maximum temperature limit, restricting the application of ITO thin films, etc., to achieve the effect of low cost, high operating temperature and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

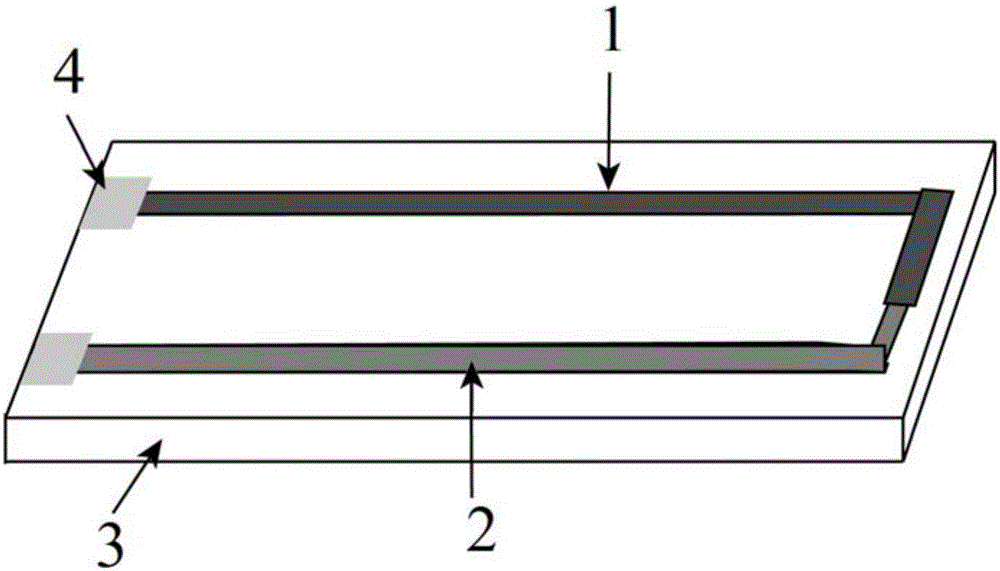

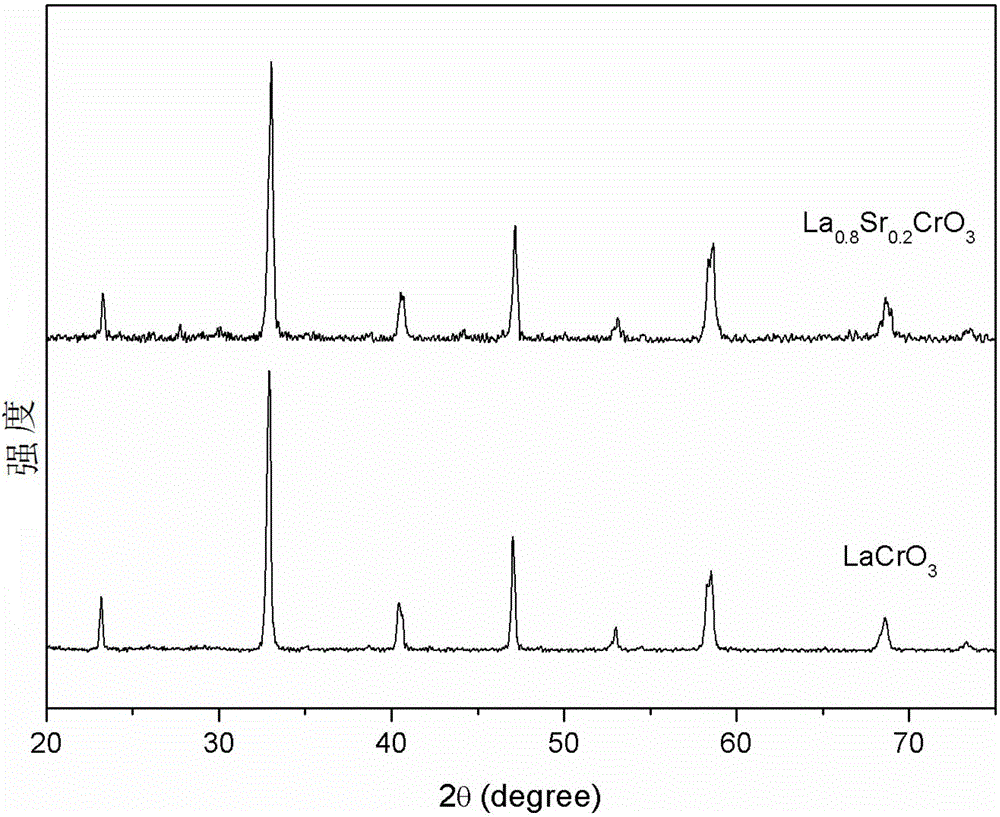

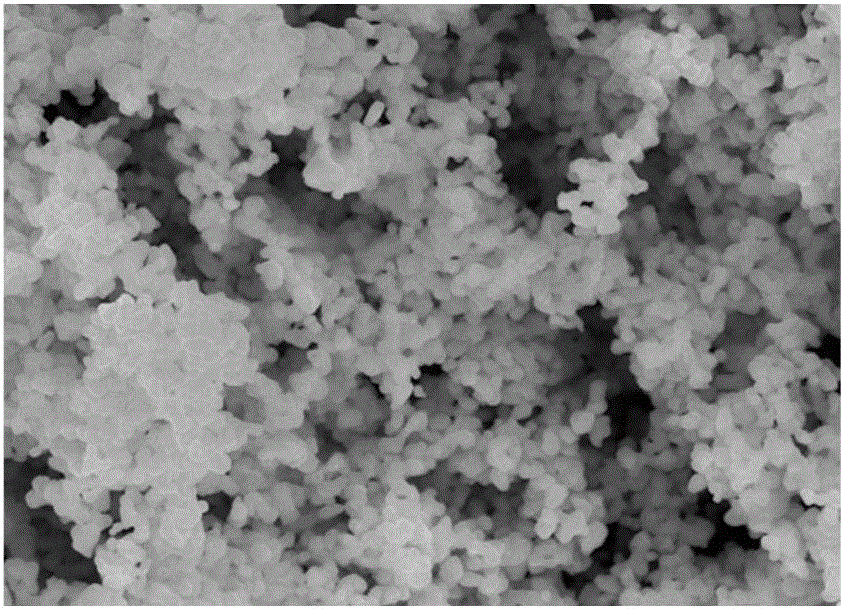

[0036] La selected 0.8 Sr 0.2 CrO 3 And LaCrO 3 The powder is used as a thermocouple electrode material, and a thick film electrode is deposited on an alumina ceramic substrate 3 with a thickness of 1 mm by a screen printing process. The ceramic slurry used for screen printing is made of La 0.8 Sr 0.2 CrO 3 And LaCrO 3 The particle size of the powder is about 200nm, using a 1:2 mixed solution of ethyl cellulose and terpineol as the organic solvent, adding the ceramic powder to the organic matter in a ratio of 1:1 and mixing with strong stirring. Ceramic paste for screen printing. In order to obtain a good patterning, a U-shaped structure mask with a thermal electrode length of 12 cm and a width of 0.8 cm was selected to prepare the thick film electrode by screen printing. The screen used was 200 mesh. Print the ITO thick film on the substrate first, and then print the indium oxide thick film. After the two thick film materials are deposited, the thick film sample is heat treated...

Embodiment 2

[0038] La selected 0.9 Sr 0.1 CrO 3 And LaCrO 3 The powder is used as the material of thermocouple electrode, and the thick film electrode is deposited on the alumina ceramic substrate with a thickness of 3mm by the screen printing process. The ceramic slurry used for the screen printing is made of La 0.9 Sr 0.1 CrO 3 And LaCrO 3 The particle size of the powder is about 100nm, using a 1:2 mixed solution of ethyl cellulose and terpineol as the organic solvent, adding the ceramic powder to the organic matter in a ratio of 2:3 and mixing vigorously as Ceramic paste for screen printing. In order to obtain a good patterning, a U-shaped structure mask with a thermal electrode length of 25 cm and a width of 1.5 cm was selected to prepare the thick film electrode by screen printing. Print LaCrO on the substrate first 3 Thick film, then print La 0.9 Sr 0.1 CrO 3 Thick film. After the two thick film materials are deposited, the thick film sample is heat treated in a muffle furnace at 1200...

Embodiment 3

[0040] La selected 0.8 Sr 0.2 CrO 3 And La 0.9 Sr 0.1 CrO 3 The powder is used as the electrode material of the thermocouple, and the thick film electrode is deposited on the alumina ceramic substrate with a thickness of 10mm by the screen printing process. The ceramic slurry used for the screen printing is made of La 0.8 Sr 0.2 CrO 3 And La 0.9 Sr 0.1 CrO 3 The particle size of the powder is about 200nm, using a 1:2 mixed solution of ethyl cellulose and terpineol as the organic solvent, adding the ceramic powder to the organic matter in a ratio of 1:1 and mixing with strong stirring. Ceramic paste for screen printing. In order to obtain a good patterning, a U-shaped structure mask with a thermal electrode length of 20 cm and a width of 1.0 cm was selected to prepare the thick film electrode by screen printing. The screen used was 200 mesh. First print the ITO thick film on the substrate, and then print the indium oxide thick film. After the two thick film materials are deposite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com