Feed applicable to industrial aquaculture of tilapia, and preparation method and feeding method thereof

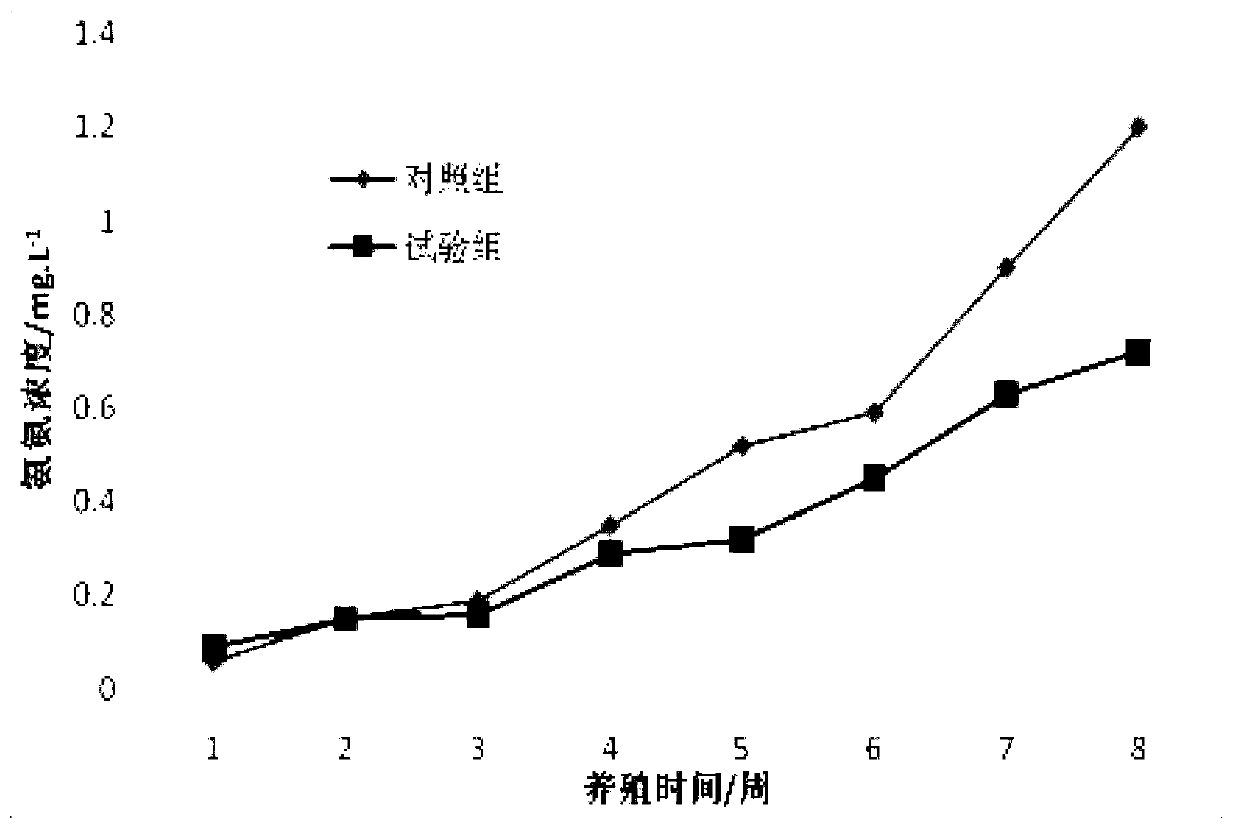

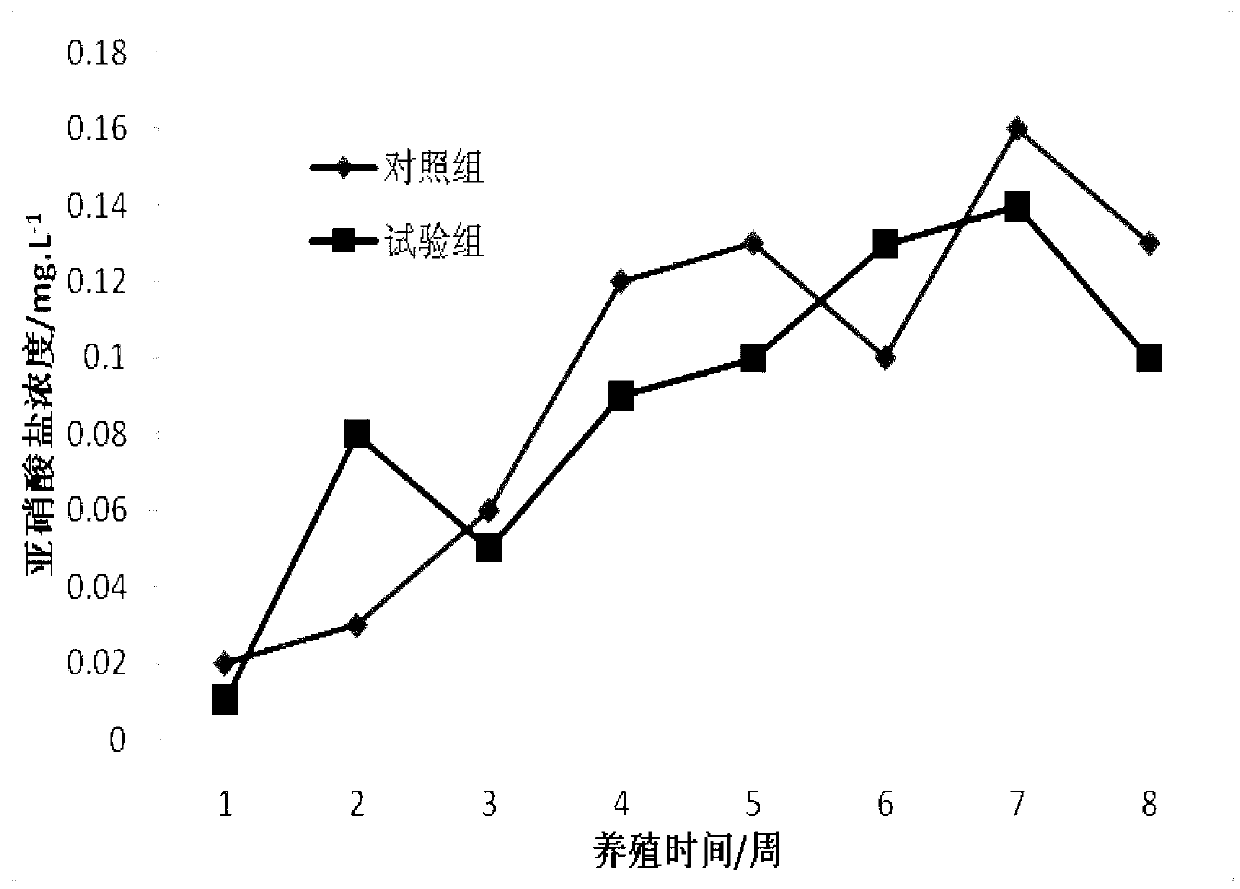

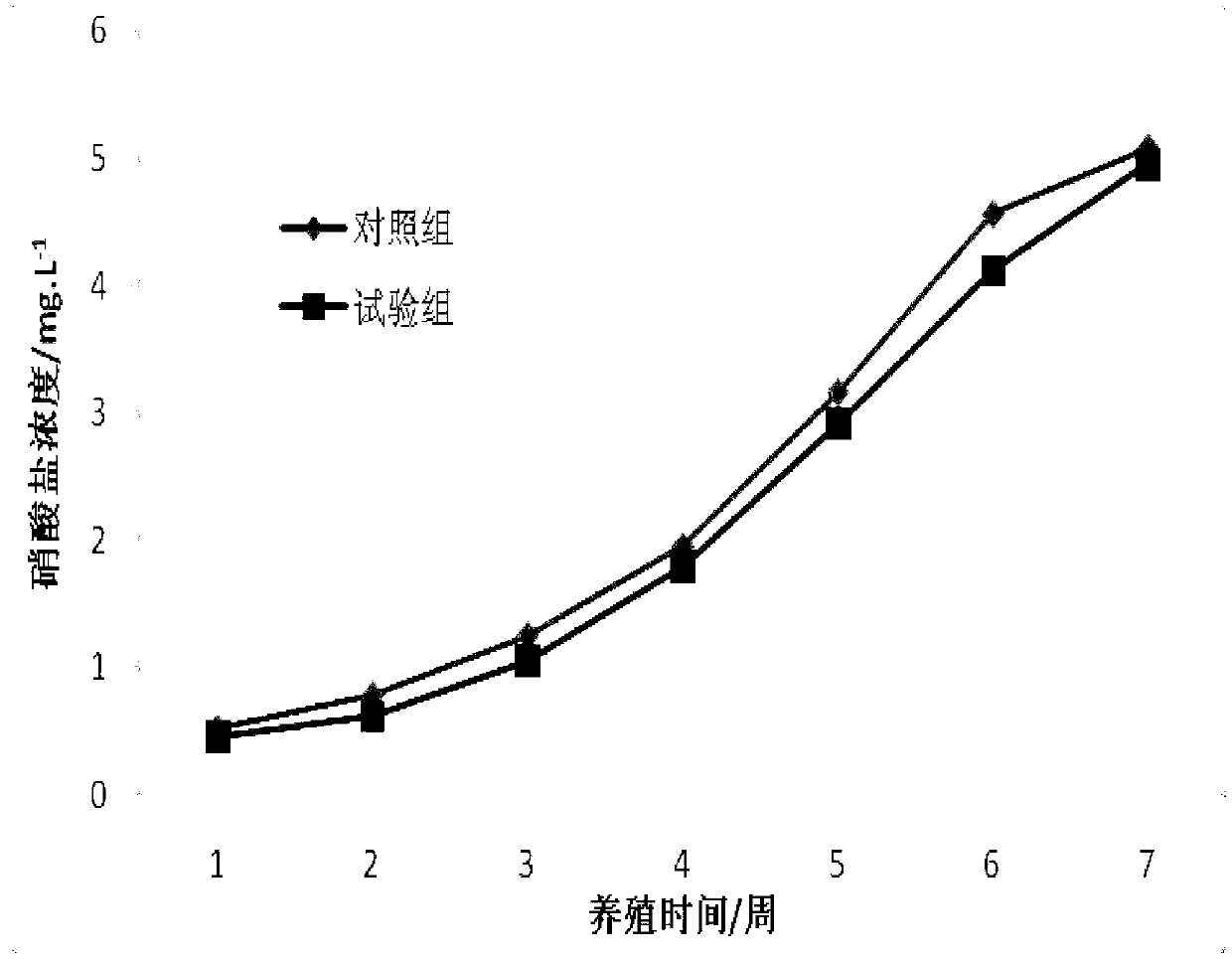

A tilapia, industrialized technology, applied in animal feed, animal feed, application, etc., can solve the problems of weakened resistance to disease, increased fish stress, and high breeding density, reducing usage and low cost. , the effect of reducing ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Feed formula:

[0045]

[0046]

[0047] Described mineral premix, by 1kg, is made up of following components: ferrous sulfate hexahydrate 1.25g, magnesium sulfate heptahydrate 47.5g, sodium carbonate 10g, aluminum chloride hexahydrate 0.1g, calcium iodate 2g , 0.1 g of copper chloride dihydrate, 0.4 g of manganese sulfate monohydrate, 0.3 g of cobalt chloride hexahydrate, 0.5 g of zinc sulfate heptahydrate, and 937.85 g of zeolite powder.

[0048] Described vitamin premix, by 1kg, consists of the following components: Vitamin B 1 5g, vitamin B 2 6.2g, calcium pantothenate 7.25g, niacin 5g, biotin 0.3g, vitamin B 6 0.8g, vitamin B 12 1g, folic acid 2g, inositol 50g, vitamin A0.5g, vitamin D 3 0.04g, Vitamin K 3 2g, wheat bran 919.91g.

[0049] The present embodiment crude protein content is 32.1%, and crude fat is 5.1%.

[0050] (2) Processing and preparation method:

[0051] (1) First weigh chicken powder, soybean meal, corn gluten meal, fermented rap...

Embodiment 2

[0066] (1) Feed formula:

[0067]

[0068]

[0069] The present embodiment crude protein content is 31.4%, and crude fat is 5.7%.

[0070] (2) Processing and preparation method:

[0071] (1) First weigh chicken powder, soybean meal, corn gluten meal, fermented rapeseed meal, fermented cotton meal, rice bran, flour and garlic residue according to the above-mentioned certain mass percentage, mix them evenly, and crush them with a grinder to make all ingredients Pass through a 60-mesh sieve;

[0072] (2) The mineral premix, vitamin premix, calcium dihydrogen phosphate, bentonite, zeolite powder, talcum powder, choline chloride, vitamin C and vitamin E are weighed according to the above-mentioned certain mass percentage, and Mix with the raw materials in step (1), and mix thoroughly with a mixer (CV≦5%);

[0073] (3) Move the mixed material described in step (2) into a conditioner, pass in water vapor at 98°C, condition for 2 minutes, and send it to an extruder for granul...

Embodiment 3

[0085] (1) Feed formula:

[0086]

[0087] The present embodiment crude protein content is 32.3%, and crude fat is 6.0%.

[0088] (2) Processing and preparation method

[0089] (1) First weigh chicken powder, soybean meal, corn gluten meal, fermented rapeseed meal, fermented cotton meal, rice bran, flour and garlic residue according to the above-mentioned certain mass percentage, mix them evenly, and crush them with a grinder to make all ingredients Pass 40 mesh sieve;

[0090] (2) The mineral premix, vitamin premix, calcium dihydrogen phosphate, bentonite, zeolite powder, talcum powder, choline chloride, vitamin C and vitamin E are weighed according to the above-mentioned certain mass percentage, and Mix with the raw materials in step (1), and mix thoroughly with a mixer (CV≦5%);

[0091] (3) Move the mixed material described in step (2) into the conditioner, pass in water vapor at 90°C, condition for 4 minutes, and send it to the extruder for granulation, with a partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com