Alkyd resin emulsion-wax composite coating release-controlling fertiliser and method for preparing same

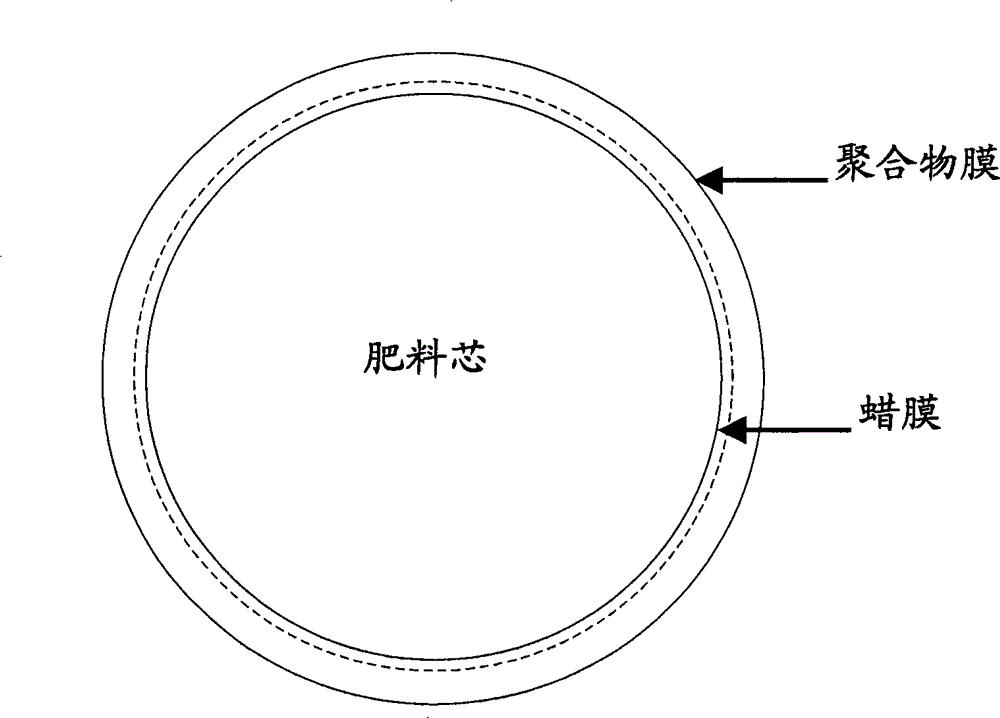

A technology of alkyd resin emulsion and controlled-release fertilizer, which is applied in fertilizer mixture, fertilization equipment, application, etc. It can solve the problems of incomplete elimination of organic solvent hazards, reduced controlled-release performance of fertilizer products, and difficulty in degrading polymer residual films. Achieve excellent controlled release properties, excellent biodegradable properties, impact and anti-wear controlled release properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In a further preferred preparation method, at first fatty acids, polyhydric alcohols and dibasic acids (and / or anhydrides thereof) derived from plants are added to a reactor equipped with a stirrer, a reflux condenser, a thermometer and nitrogen protection, and the temperature is raised to React at 160-260°C for 0.5-6 hours, preferably at 200-240°C for 2-4 hours, and use a water eliminator to remove the water generated in the reaction in time, then cool down to 120-200°C, add other polyacids (and / or their acid anhydride), heat the reaction for at least 0.5 hours, and use a water eliminator to remove the water generated in the reaction in time. Optionally, when the temperature is lowered to 130-160°C, add 2-20% by weight of rosin based on the total weight of the resin, preferably 3-10% by weight, and react at this temperature for 5 minutes to 2 hours, preferably 10 minutes to 0.5 hours . After cooling down, an alkyd resin prepolymer with a certain acid value is obtained...

Embodiment 1

[0053] (1) Preparation of alkyd resin prepolymer

[0054] Add 480 grams of linseed oil, 236 grams of trimethylolpropane and 166 grams of isophthalic acid into a reaction kettle equipped with a stirrer, reflux condenser, thermometer and nitrogen protection, raise the temperature to 235 ° C for 3.5 hours, and then cool down To 175 ° C, add 73 grams of trimellitic anhydride, react at this temperature for about 3 hours, and use a water remover to remove the water generated in the reaction in time, when the acid value of the system reaches 62KOH mg / g resin, cool down to 150 ° C, add 49 Gram rosin was reacted for 20 minutes.

[0055] (2) Preparation of alkyd resin emulsion coating agent

[0056] Cool the alkyd resin prepolymer in step (1) to 65° C., and add 20% by weight of ammonia water under stirring to make the pH of the system 7. Then add deionized water, stir and emulsify evenly, then cool to room temperature, then add 2 grams of cobalt naphthenate, 1 gram of zirconium naphth...

Embodiment 2

[0061] (1) Preparation of alkyd resin prepolymer

[0062] Add 190 grams of linseed oil, 210 grams of dehydrated castor oil, 223 grams of trimethylolpropane and 148 grams of phthalic anhydride into a reactor equipped with a stirrer, reflux condenser, thermometer and nitrogen protection, and raise the temperature to 225 °C for 2.5 hours. Then cool down to 170°C, add 64 grams of trimellitic acid, react at this temperature for about 3.5 hours, and use a water remover to remove the water generated in the reaction in time. When the acid value of the system reaches 55mgKOH / g resin, cool down to 160 ℃, add 60 grams of rosin and react for 15 minutes.

[0063] (2) Preparation of alkyd resin emulsion coating agent

[0064] Cool the alkyd resin prepolymer in step (1) to 75° C., and add 20% by weight of ammonia water under stirring to make the pH of the system 7.5. Then add deionized water, stir and emulsify evenly, then cool to room temperature, then add 1.8 grams of cobalt naphthenate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com