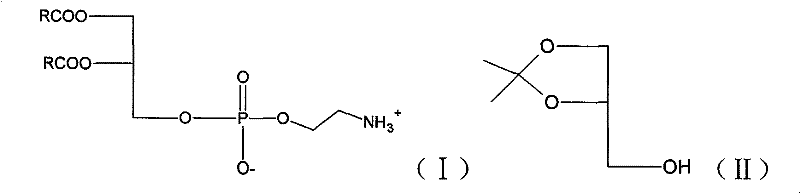

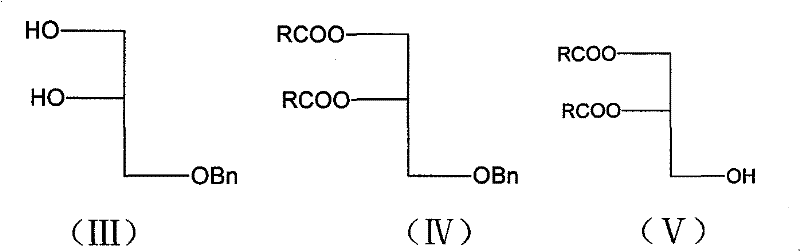

Method for preparing bi-axungia acyl-phosphatidylethanolamine

A technology of stearyl phosphatidylethanolamine and benzyl distearoylglyceride, which is applied in the direction of phosphorus organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 2: Preparation of isopropylidene-D-mannitol

[0043] 100g (0.73mol) of zinc chloride was dissolved in 500ml of acetone solution, heated to reflux for 30 minutes, added 50g (0.27mol) of D-mannitol to continue the reaction for 2 hours, then added 200ml of chloroform, and extracted with 200ml of saturated sodium chloride for phase separation. Add 400 ml of 5% ammonia solution to the organic phase, dry the organic phase with anhydrous magnesium sulfate, and concentrate by rotary evaporation to obtain 49 g of white solid product isopropylidene-D-mannitol.

Embodiment 2

[0044] Embodiment 3: preparation isopropylidene glycerol

[0045] Dissolve 53.9g (0.25mol) of sodium periodate in 430ml of water, add 36g (0.14mol) of isopropylidene D-mannitol in 180ml of isopropanol solution, control the temperature at 35°C, react for 50 minutes, and then add 860ml isopropanol, filter the insoluble matter, add 15.8 g (0.42 mol) of sodium borohydride to the filtrate, continue the reaction for 30 minutes, and control the temperature at 40 ° C, then extract, dry, and concentrate under reduced pressure to obtain a yellow-green liquid, which is then reduced to Pressure distillation obtained 32 g of isopropylidene glycerol. Bp. 10mm 77-79°C, [α] 20 D +15.2.

Embodiment 3

[0046] Embodiment 4: preparation isopropylidene glycerol

[0047] Dissolve 44.9g (0.21mol) of sodium periodate in 225ml of water, add 36g (0.14mol) of isopropylidene-D-mannitol in 150ml of methanol solution, control the temperature at 40°C, react for 20 minutes, then add 113ml of methanol , filter the insoluble matter, add 11.7g (0.31mol) of sodium borohydride to the filtrate, continue the reaction for 10 minutes, control the temperature at 60°C, then extract, dry, and concentrate under reduced pressure to obtain a yellow-green liquid, which is then obtained by distillation under reduced pressure 30.1 g of isopropylidene glycerol. Bp. 10mm 77-79°C, [α] 20 D +15.21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com