Elastic body fine crushing combined apparatus and collocation method

A combined device and elastomer technology, applied in plastic recycling, recycling technology, grain processing, etc., can solve the problems of poor performance, increase of coarse material, increase of coarse powder return, etc., and achieve the effect of optimizing the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

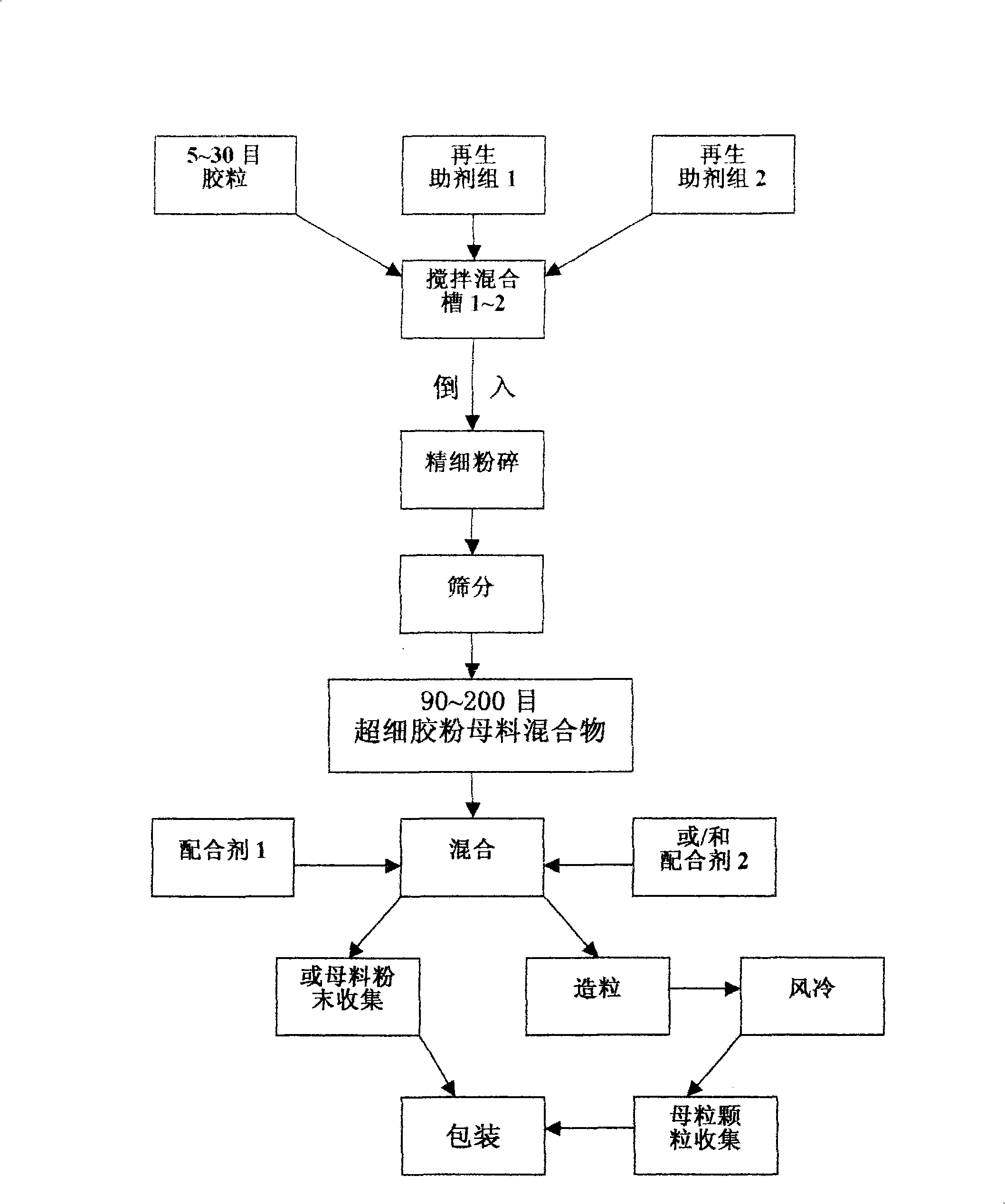

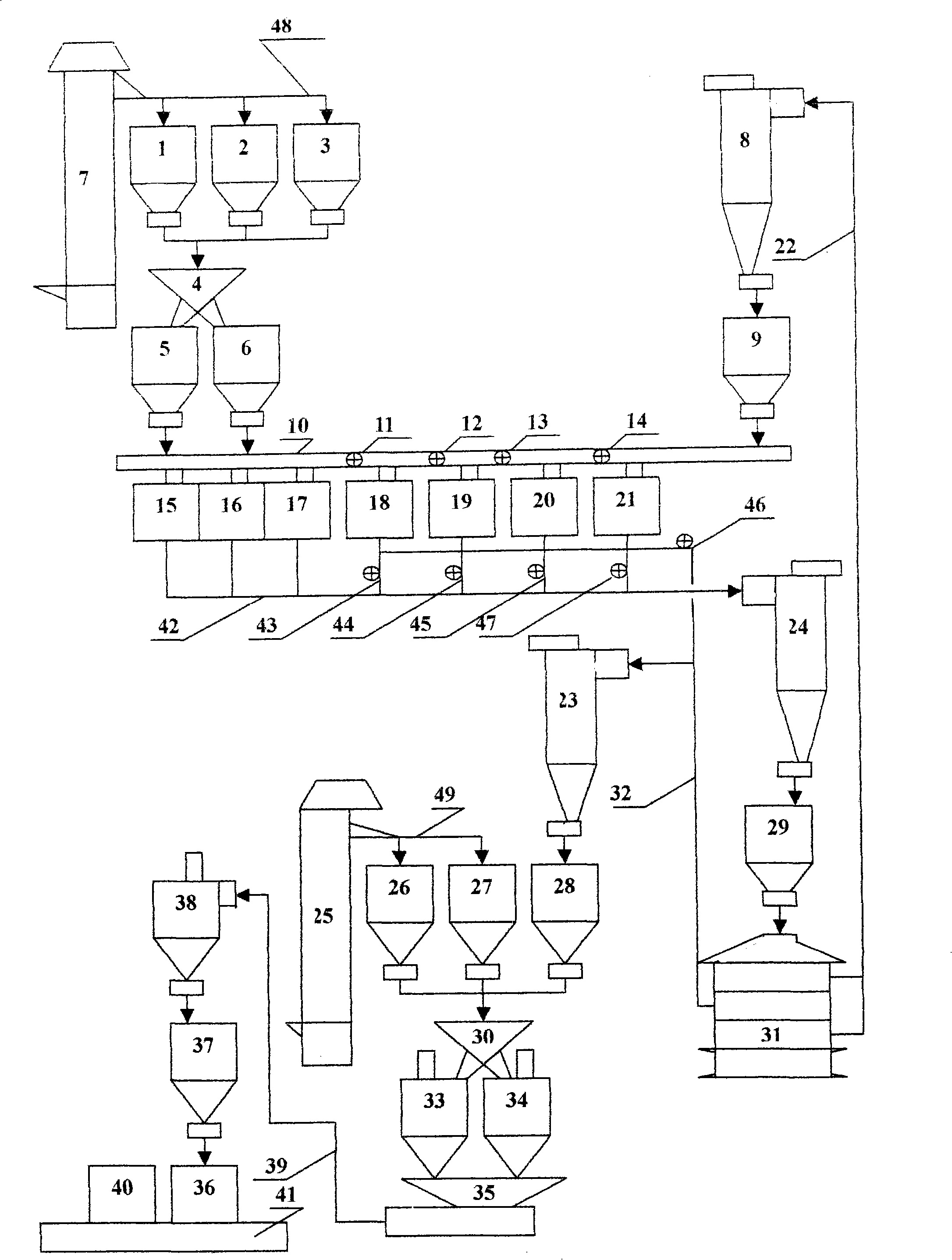

[0063] For such as attached figure 1 The above-mentioned one uses 5-30 mesh elastomer colloids as raw materials, adds regeneration aid group powder, and first prepares 90-200 mesh superfine rubber powder masterbatch mixture by normal temperature fine pulverization method, then adds compounding agent, and then Then make the masterbatch or directly add the masterbatch mixture of the compounding agent and pack it into the bag according to the technical process requirements. figure 2 The shown set of elastomer colloids is finely pulverized at room temperature and then made into masterbatches. Before and after the processing process, auxiliary materials can be added under closed working conditions; the fine crushing unit group is divided into two groups, A and B, which ensures the constant feed composition and particle size of the fine crushing machine, and facilitates the steady flow of coarse rubber materials into the machine; There is a feed flow ratio adjustment device on the...

Embodiment 2

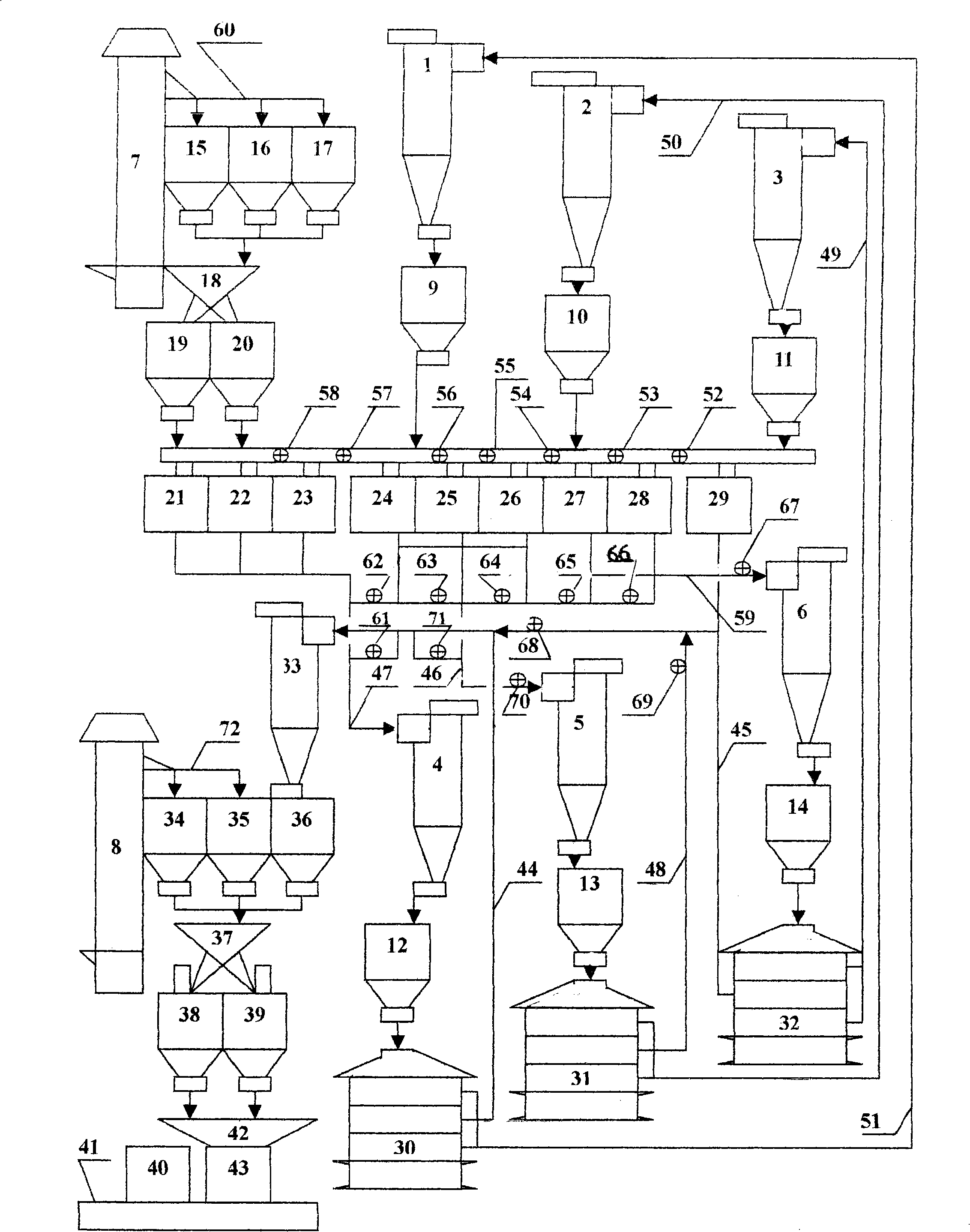

[0078] For such as attached figure 1 Described technological process requirement, the present invention cooperates technological requirement again, integrates and combines again as attached image 3Another set of elastomer colloidal particles shown is finely pulverized at room temperature, and then made into a masterbatch powder mixture. Before and after the fine crushing process, auxiliary materials can be added under airtight conditions; the fine crushing unit group can be divided into two groups A and B, or three groups A, B, and C, or four groups A, B, C, and D, ensuring fine crushing The feed composition and particle size of the machine are constant, which is convenient for the steady flow of coarse rubber materials into the machine; there is a feed flow ratio adjustment device on the feed pipeline of the fine crusher group; Coarse powder passing through a sieve of 90~ or 150~ or 200~ mesh flows in parallel with superfine powder passing through a mesh of 250~350 mesh, an...

Embodiment 3

[0107] For such as attached figure 1 According to the requirements of the technological process, the present invention cooperates with the technological requirements and integrates another set of elastomer colloids as shown in Figure 4. First, it is finely pulverized at room temperature, and then the auxiliary materials are added to make rubber powder and auxiliary materials. The combination device of the masterbatch is characterized in that: before and after the fine crushing unit groups 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, there are machines that can add auxiliary materials, elastomers Colloidal particles can be added auxiliary materials under airtight conditions before and after the fine crushing process; the fine crushing unit group only has group A; Collected together through the collection hopper 45, and sent to the storage bin 4 of the batching section by the conveyor 44, and then the small amount of returned material is matched with the new material in proport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com