Coating agent for forming titanium/zirconium film, method for forming titanium/zirconium film and metal substrate coated with titanium/zirconium film

A technology for metal substrates and coating agents, which can be used in devices, chemical instruments and methods for coating liquids on surfaces, polyurea/polyurethane coatings, etc., and can solve problems such as inability to form dense films, corrosion, and restrictions on use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

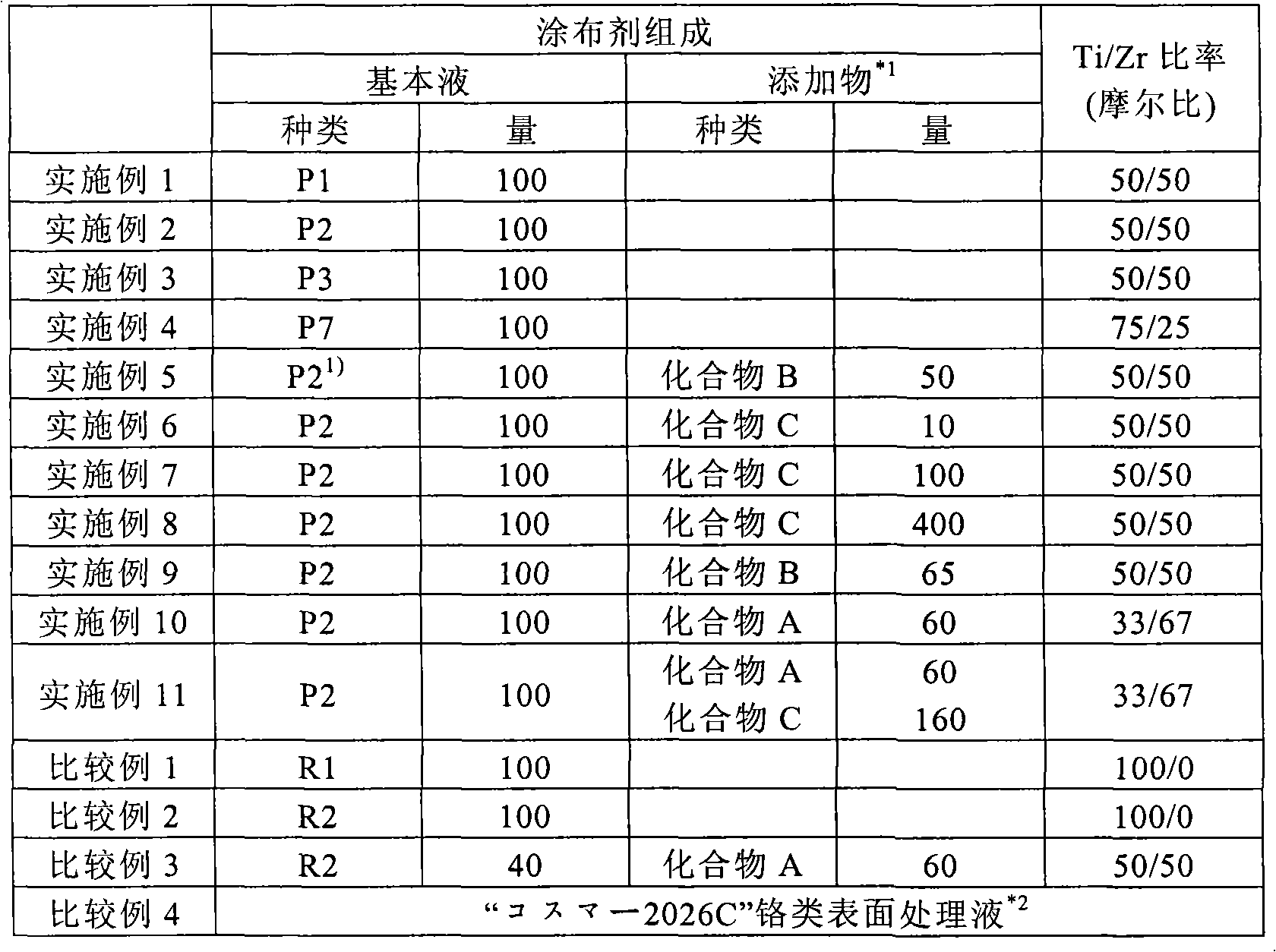

manufacture example 1

[0150] Adjust the pH of 100 parts of 35% hydrogen peroxide to 8.4 with ammonia water, and cool to 10° C. in an ice bath. Here, 1.4 parts of tetraisopropoxytitanium and 1.63 parts of tetra-n-propoxyzirconium were added dropwise over 1 hour while stirring. Filter the obtained orange-red transparent liquid, add 0.5 parts of 10% ammonia water and stir well, add deionized water to prepare a titanium-zirconium-containing aqueous solution P1 with a metal oxide concentration of 1%.

manufacture example 2

[0152] In 2000 parts of deionized water, 13 parts of titanium tetraisopropoxide and 20 parts of zirconium tetra-n-propoxide were added dropwise while stirring to carry out hydrolysis. The deposited precipitate was filtered and washed with water to obtain a titanium-zirconium hydrolyzate. Add 20 parts of 25% ammonia water to 100 parts of 35% hydrogen peroxide, and cool to 10° C. in an ice bath. There, the titanium-zirconium hydrolyzate was added over 30 minutes. After further reacting for 30 minutes, 50 parts of 60% 1-hydroxyethane-1,1-diphosphonic acid were added, followed by further stirring for 30 minutes. The obtained orange-red transparent liquid was filtered, and deionized water was added to prepare a titanium-zirconium-containing aqueous solution P2 with a metal oxide concentration of 5%.

manufacture example 3

[0154] Adjust the pH of 100 parts of 35% hydrogen peroxide to 8.4 with ammonia water, and cool to 10° C. in an ice bath. Here, 1.4 parts of tetraisopropoxytitanium and 1.63 parts of tetra-n-propoxyzirconium were added dropwise over 1 hour while stirring. After further reacting for 2 hours, 3.0 parts of ammonium glycolate was added, followed by further stirring for 30 minutes. The obtained orange-red transparent liquid was filtered, and deionized water was added to prepare a titanium-zirconium-containing aqueous solution P3 with a metal oxide concentration of 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com