Light emitting diode and laser and their production method

A technology of light-emitting diodes and manufacturing methods, which is applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as inability to prepare high-performance, cracking of thin-film materials, etc., and achieve the effects of reducing substrate costs and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

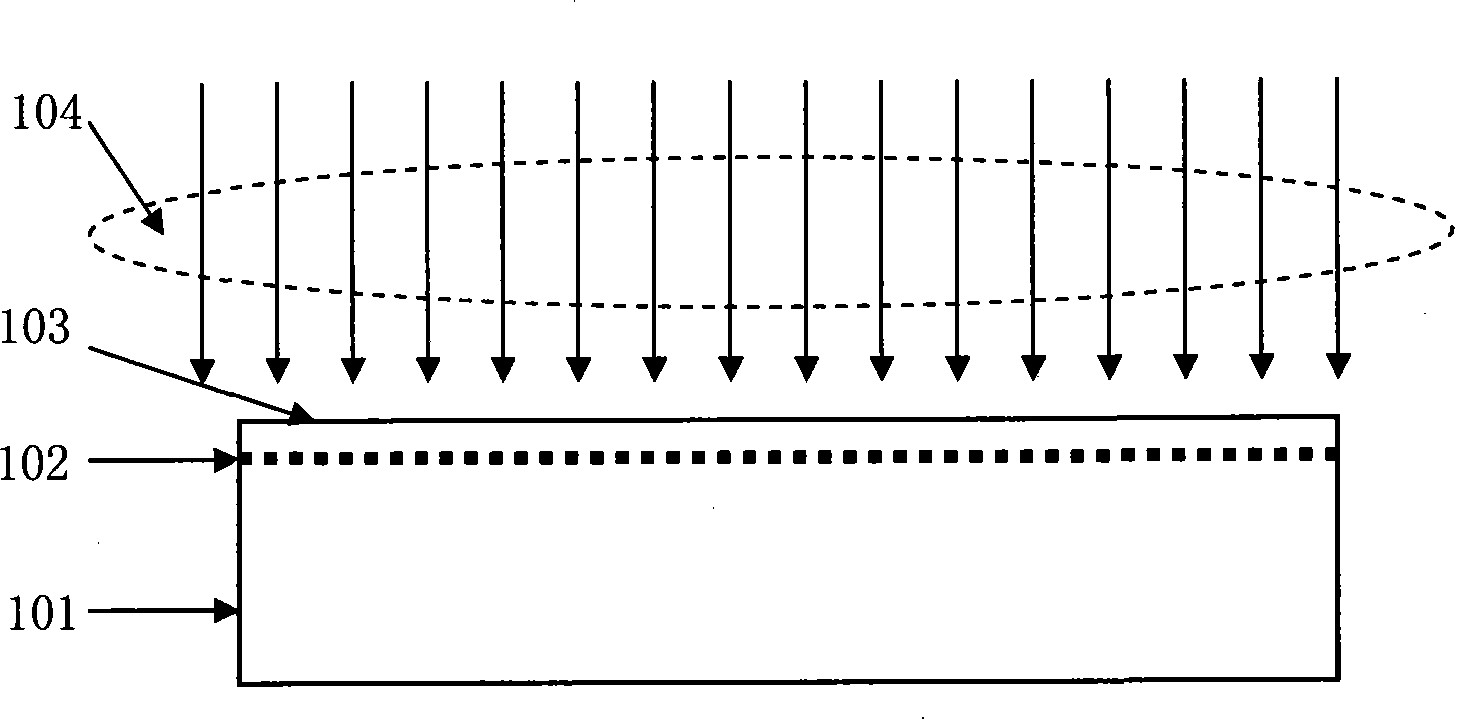

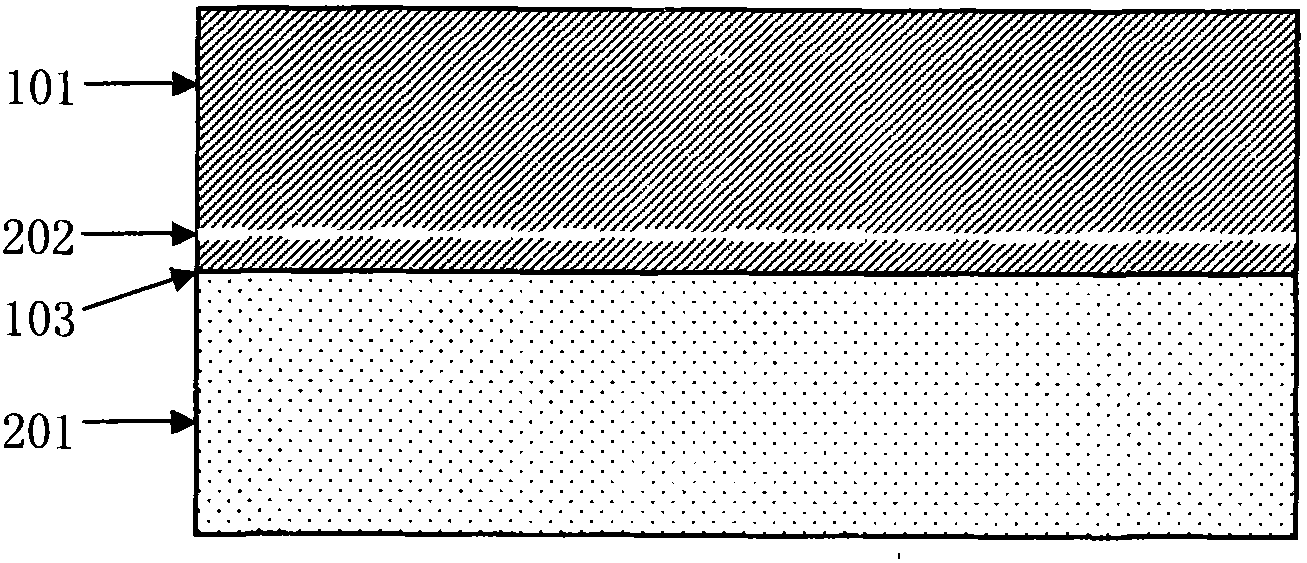

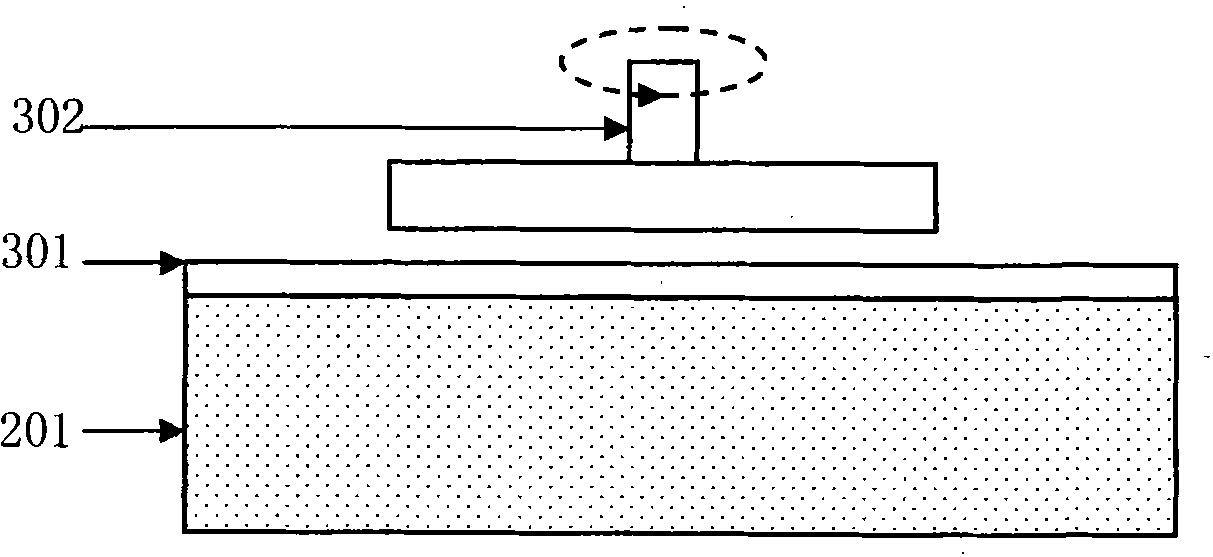

[0054] The manufacturing method of the light-emitting diode and the laser, as well as the light-emitting diode and the laser of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0055] The manufacturing method of semiconductor light-emitting diode (LED) and laser (LD) of the present invention, described light-emitting diode and semiconductor laser are direct epitaxial growth on single crystal silicon thin-film quartz (SOQ) substrate or epitaxial growth is deposited on buffer layer on single crystal silicon thin film quartz (SOQ) substrates.

[0056] The manufacturing method of semiconductor light-emitting diode and laser of the present invention specifically comprises the following steps:

[0057] (1) Chemical-mechanical polishing (CMP) of the single crystal silicon wafer reaches a set thickness, the set thickness is 100nm-300nm, and then large-dose hydrogen ion implantation is performed within the set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com