Method for preparing high-performance WC/MgO nano composite material

A nano-composite material and nano-composite technology, applied in the field of preparation of high-performance WC/MgO nano-composite materials, can solve problems such as sacrificing toughness and decreasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

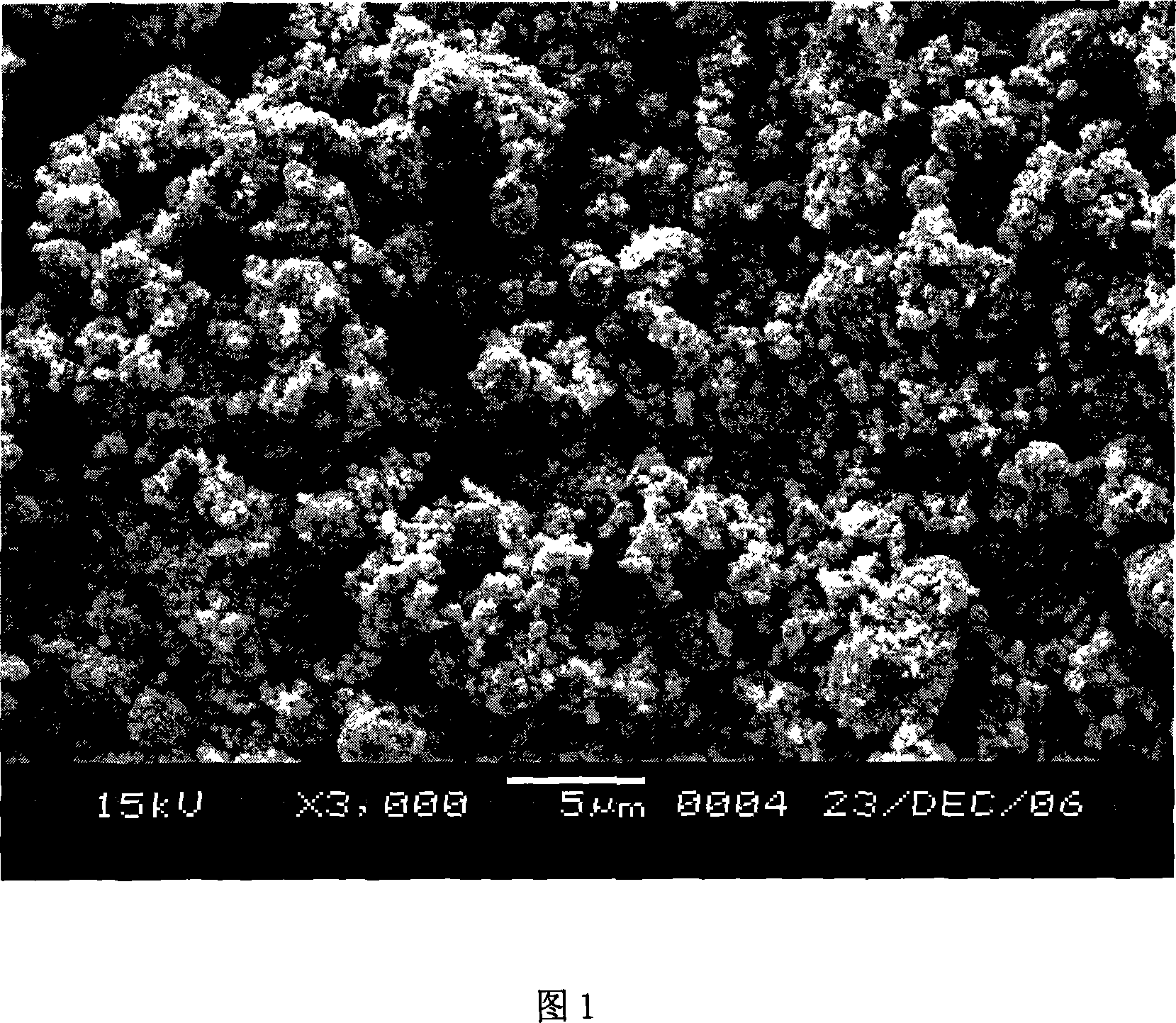

[0026] Mix 0.1 mol of WC with a particle size of 1 μm and 0.1 mol of MgO powder with a particle size of 5 μm, and put them into a ball mill jar; add stearic acid with a mass percentage of 3%; ball; the ball mill jar is sealed and evacuated, and then filled with argon; the ball mill jar is installed on the planetary ball mill, and the outer cover is covered, and the ball mill is continuously ball milled for 50 hours at 250r / min to obtain a powder particle size of 80nm WC / MgO nano-composite powder; dry the obtained WC / MgO nano-composite powder in a vacuum oven, put it into a mold, and cold press it; then put the compact into a spark plasma sintering equipment for sintering, and the sintering system is: 1510°C, the heating rate is 80°C / min, the sintering pressure is 48MPa, and the sintering temperature and sintering pressure are kept for 3 minutes, and the ultrafine WC / MgO nanocomposite powder can be prepared, and SEM, TEM and performance tests are carried out on it .

Embodiment 2

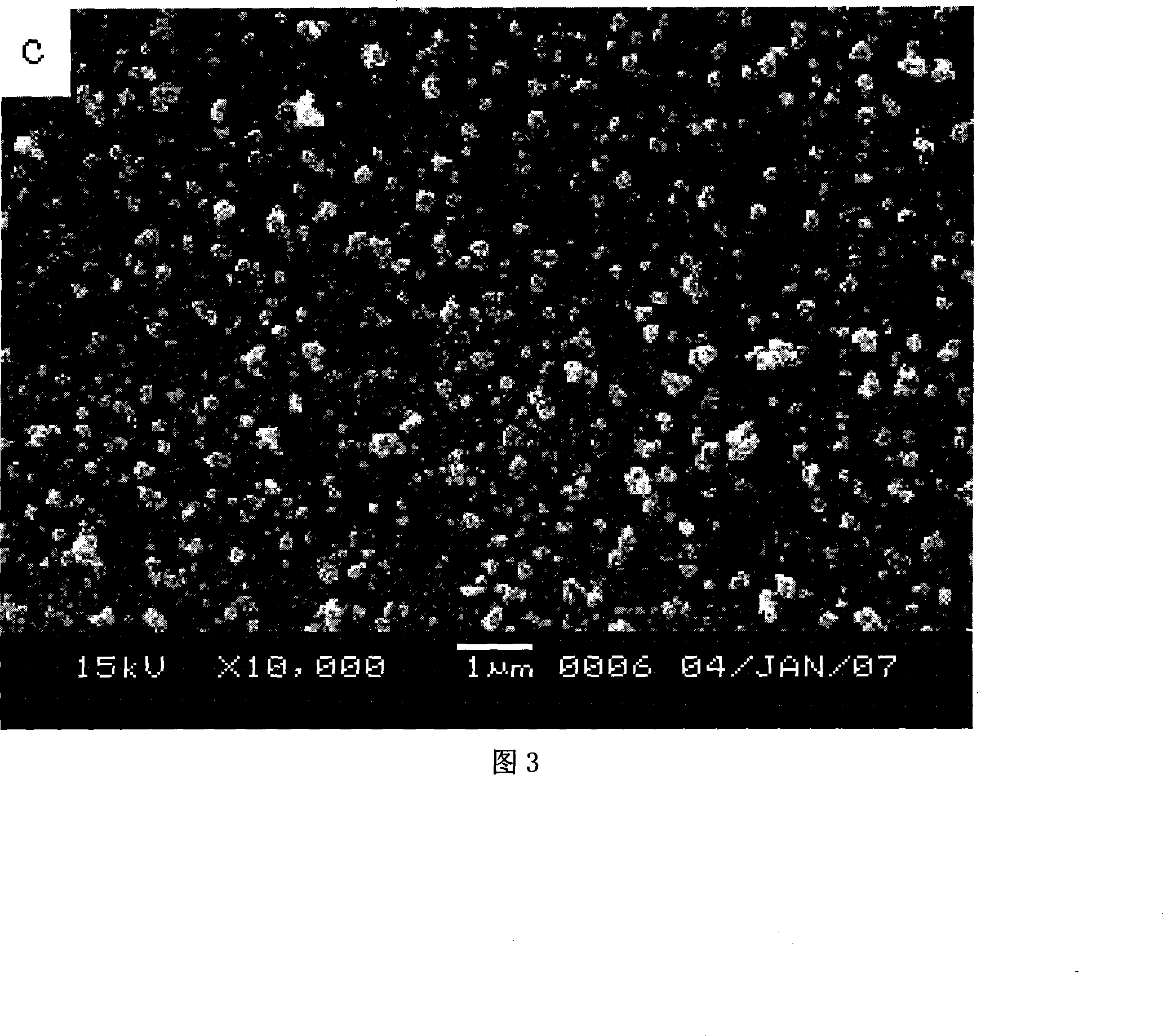

[0028] Mix 0.3 mol of WC with a particle size of 3 μm and 0.5 mol of MgO powder with a particle size of 4 μm, and put it into a ball mill jar; add 0.5% stearic acid in a mass percentage; Put the ball into the grinding ball; seal the ball mill tank, vacuumize it, and then fill it with argon; install the ball mill tank on the planetary ball mill, cover the outer cover, and continue ball milling at 500r / min for 70 hours to obtain powder particles WC / MgO nanocomposite powder with a diameter of 150nm; the obtained WC / MgO nanocomposite powder is dried in a vacuum drying oven and then put into a mold for cold pressing; then the compact is put into a spark plasma sintering device for sintering, The sintering system is as follows: the sintering temperature is 1530°C, the heating rate is 100°C / min, the sintering pressure is 49MPa, and the ultrafine WC / MgO nanocomposite powder can be prepared by keeping the temperature and pressure for 4 minutes. SEM, TEM and performance testing.

Embodiment 3

[0030] Mix 0.1 mol of WC with a particle size of 5 μm and 0.3 mol of MgO powder with a particle size of 1 μm, and put it into a ball mill jar; add stearic acid with a mass percentage of 2%; ball; the ball mill jar is sealed and evacuated, and then filled with argon; the ball mill jar is installed on the planetary ball mill, and the outer cover is covered, and the ball mill is continuously ball milled at 450r / min for 62 hours to obtain a powder particle size of 150nm WC / MgO nano-composite powder; dry the obtained WC / MgO nano-composite powder in a vacuum oven, put it into a mold, and cold press it; then put the compact into a spark plasma sintering equipment for sintering, and the sintering system is: 1520°C, the heating rate is 90°C / min, the sintering pressure is 52MPa, and the sintering temperature and sintering pressure are kept for 5 minutes to prepare ultrafine WC / MgO nanocomposite powder, and conduct SEM, TEM and performance tests on it .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com