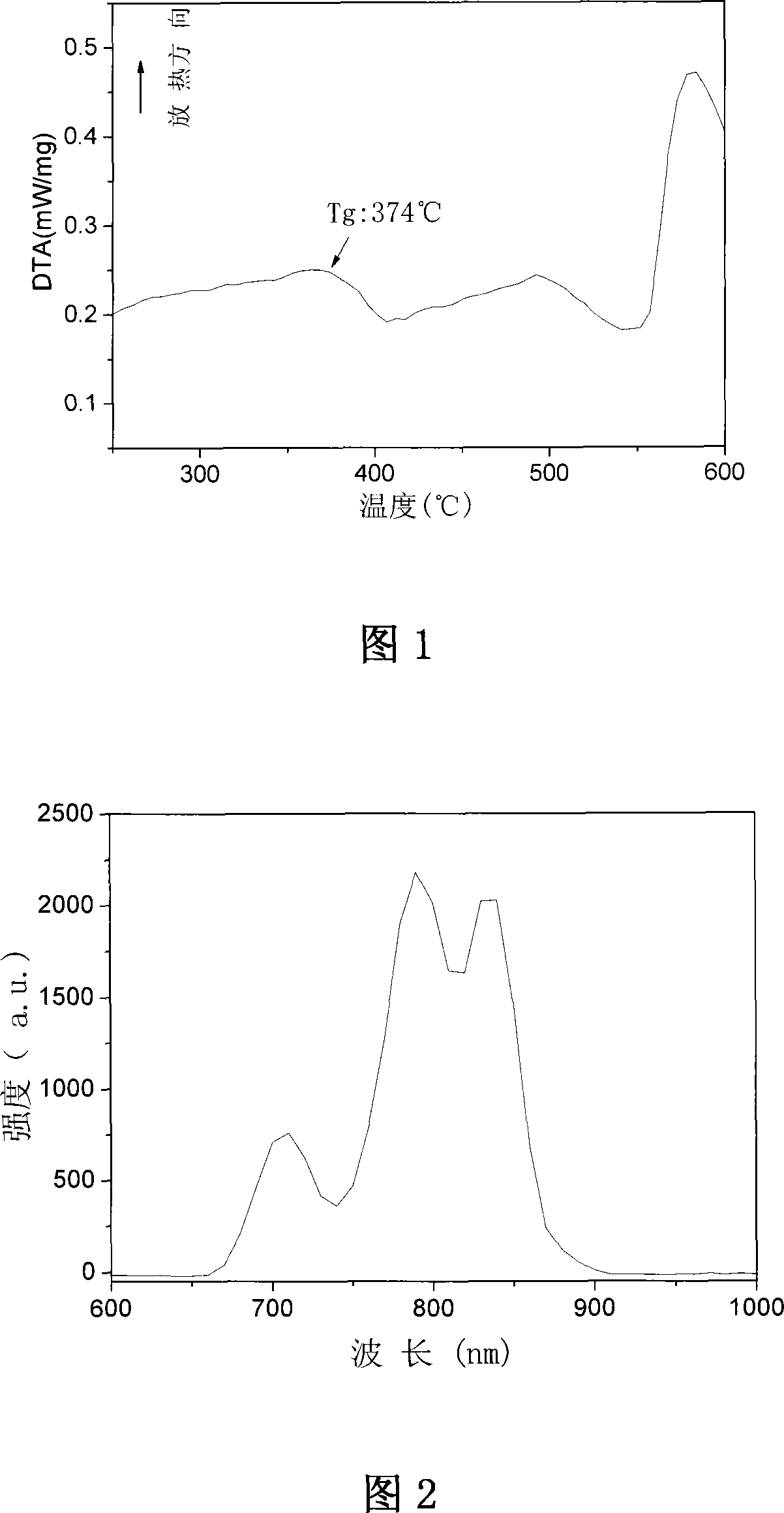

Tellurate glass and method for producing the same

A tellurite glass and glass technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of poor supercontinuum output quality, high nonlinear coefficient, high welding loss, etc., and achieve excellent physical and chemical properties , Good physical and chemical stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Select the glass formula according to the first group of components in Table 1, weigh each raw material, and the purity of the raw material is more than 99.9%, and mix and stir the prepared powdery raw materials evenly to form a mixture;

[0044] (2) Put the mixture into a platinum crucible, place it in a silicon carbide rod electric furnace, and melt it at a melting temperature of 900 to 1000°C. During the melting process, dry nitrogen gas is introduced to protect the atmosphere. A platinum cover with stirring blades is added to prevent the entry of water molecules in the external air;

[0045] (3) After the raw materials are completely melted, continue to raise the temperature to 1100-1200°C, and stir with a platinum propeller at 60 rpm for 60 minutes to make F - The ions are completely volatilized as far as possible, and the [OH in the glass liquid is taken away - ]; then lower the temperature at 150°C / hour, and at the same time adjust the stirring speed to 30 r...

Embodiment 3

[0049] (1) Select the glass formula according to the third group of components in Table 1, weigh each raw material, the purity of the raw material is more than 99.9%, and mix and stir the prepared powdery raw material evenly;

[0050] (2) Put the mixture into a platinum crucible, place it in a silicon carbide rod electric furnace, and melt it at a melting temperature of 850-950°C. During the melting process, dry nitrogen gas is introduced to protect the atmosphere. At the same time, add Platinum lid with stirring blades to prevent the entry of water molecules from the outside air;

[0051] (3) After the raw materials are completely melted, continue to increase the temperature to 1100-1150°C, and stir with a platinum propeller at 80 rpm for 40 minutes to make the F evaporate as completely as possible and take away the [OH in the glass liquid - ]; then lower the temperature at 100°C / hour, and at the same time adjust the stirring speed to 20 rpm and continue to stir for 45 minute...

Embodiment 5

[0055] (1) Select the glass formula according to the fifth group of components in Table 1, weigh each raw material, the purity of the raw material is more than 99.9%, and mix and stir the prepared powdery raw material evenly;

[0056] (2) Put the mixture into a platinum crucible, place it in a silicon carbide rod electric furnace, and melt it at a melting temperature of 800-850°C. During the melting process, dry nitrogen gas is introduced for atmosphere protection, and at the same time, add Platinum lid with stirring blades to prevent the entry of water molecules from the outside air;

[0057] (3) After the raw materials are completely melted, continue to raise the temperature to 950-1000°C, and stir with a platinum propeller at 60 rpm for 90 minutes to make the F evaporate as completely as possible and take away the [OH in the molten glass. - ]; then lower the temperature at 100°C / hour, and at the same time adjust the stirring speed to 30 rpm and continue to stir for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com