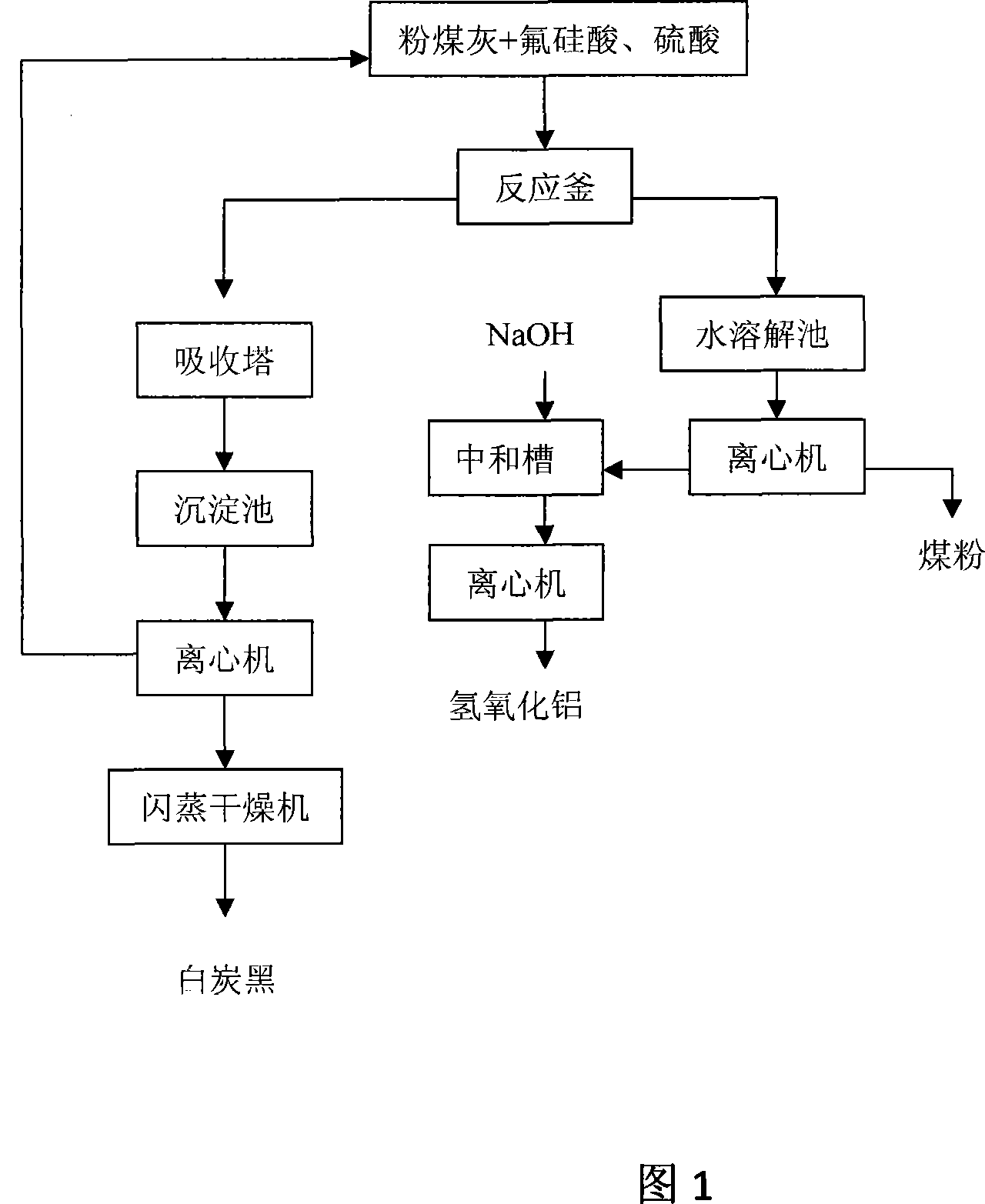

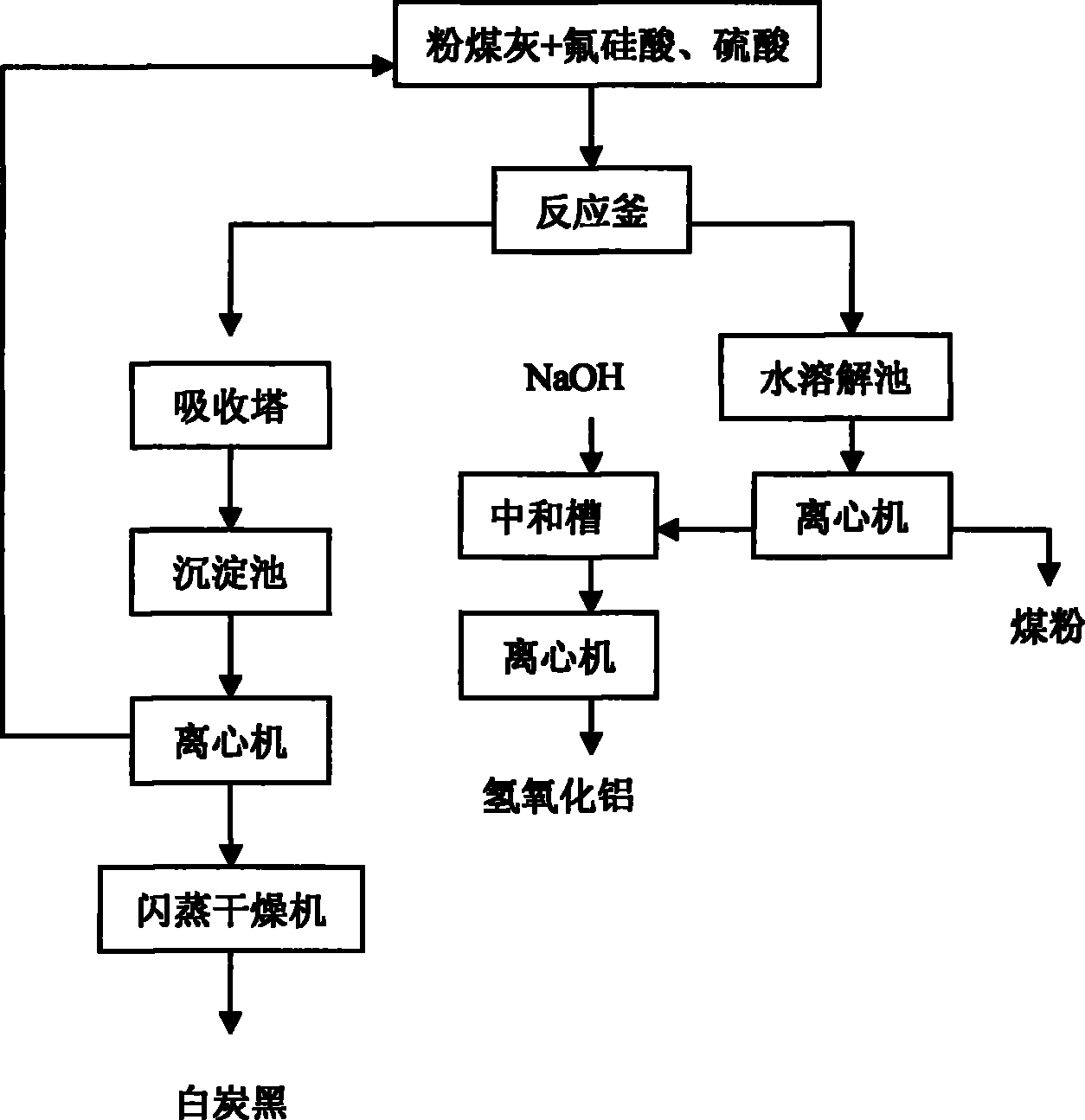

Method for preparing white carbon black, coal powder and aluminum hydroxide from fly ash

A technology of fly ash and white carbon black is applied in the field of utilization of fly ash, which can solve the problems of high cost, high energy consumption, and low utilization value of silica, achieve high added value, and solve the effect of accumulation and occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 8 cubic meters of 20% fluosilicic acid and 0.5 cubic meters of 30% sulfuric acid into the reaction kettle, add 1000 kg of fly ash after heating to 80°C, heat and stir to react, and control the reaction temperature at 120°C until the reaction After completion, evaporate to dryness to obtain a solid reaction product. At the same time of the reaction, the gas generated by the reaction is drawn into the absorption tower, and the solid precipitation produced in the sedimentation tank at the bottom of the absorption tower is separated by a centrifuge, and the solid precipitation is washed to a pH value of 3, and the slurry concentration is 10%. Dry the flash dryer to obtain white carbon black; dissolve the solid reaction product in the reactor with 10 times the water of the solid reaction product, centrifuge and separate the solid and liquid, dry the solid part to obtain coal powder, and drip the liquid under stirring Add 20% ammonia water to adjust the pH value to 6 to o...

Embodiment 2

[0022] Add 6 cubic meters of 30% fluosilicic acid and 0.3 cubic meters of 60% sulfuric acid into the reaction kettle, heat to 100°C, add 1,000 kg of fly ash under constant stirring, and slowly raise the temperature to 150°C until the reaction is complete , and evaporated to dryness to obtain a solid reaction product. At the same time of the reaction, the gas generated by the reaction is drawn into the absorption tower, and the solid precipitation produced in the sedimentation tank at the bottom of the absorption tower is separated by a centrifuge, and the solid precipitation is washed to a pH value of 5, and the slurry concentration is 30%. Dry with a flash dryer to obtain white carbon black; dissolve the solid reaction product in the reactor with 7 times the water of the reactant, centrifuge to separate the solid and liquid, dry the solid part to obtain coal powder, and add the liquid dropwise for 25 % ammonia water to adjust the pH value to 8 to obtain aluminum hydroxide pre...

Embodiment 3

[0024] Add 3 cubic meters of fluosilicic acid with a concentration of 45%, 0.2 cubic meters of 98% sulfuric acid, and 1,000 kilograms of fly ash into the reaction kettle, heat and stir the reaction, control the reaction temperature at 180°C until the reaction is completed, and evaporate to dryness to obtain a solid reaction. product. At the same time of the reaction, the gas generated by the reaction is drawn into the absorption tower, and the solid precipitation produced in the sedimentation tank at the bottom of the absorption tower is separated by a centrifuge, and the solid precipitation is washed to a pH value of 6, and the slurry concentration is 40%. Dry the flash dryer to obtain white carbon black; dissolve the solid reaction product in the reaction kettle with 3 times the water of the solid reaction product, centrifuge and separate the solid and liquid, dry the solid part to obtain coal powder, and drip the liquid under stirring Add 30% ammonia water to adjust the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com