A method of sludge carbonization and reburning

A sludge charcoal and sludge technology, applied in chemical instruments and methods, sludge treatment, pyrolysis sludge treatment, etc., can solve the problems of large electricity consumption, high sludge carbonization cost and low utilization rate, etc. The effect of solving energy regeneration, reducing electricity consumption and enriching the carbon energy market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

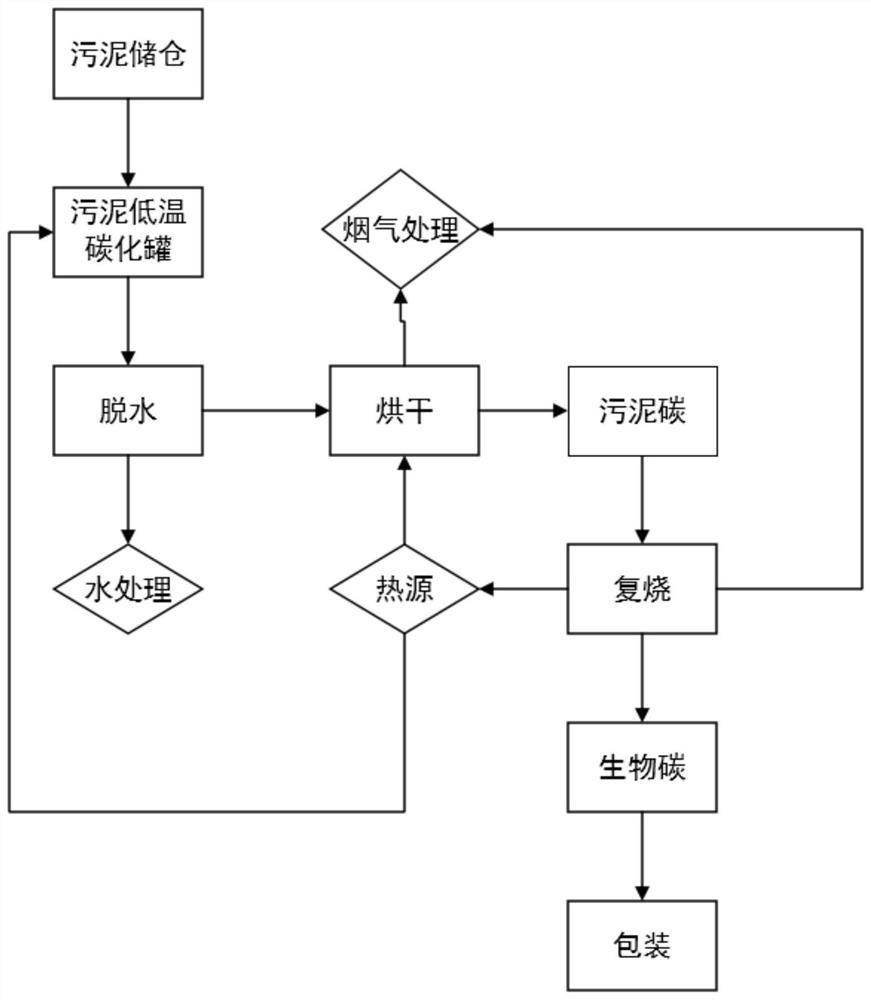

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 as shown,

[0028] The feature of this embodiment is that it is a method for sludge carbonization and reburning, which includes the following steps: (1) Preheating process: transport the sludge to be treated to the preheating tank through the transport device and preheat it to 100°C-120°C ℃; (2) reaction tank reaction: transport the sludge preheated in step (1) to the reaction tank through the transport device at a temperature of 150 ℃, and the pressure is controlled at 7Mpa to stir and react, and keep the reaction for no less than 10min ~ 12min, The flue gas generated during the reburning process and the waste heat of the main furnace are introduced into the flue gas pipeline by the fan; (3) Cooling and cooling: transport the reacted sludge in step (2) to the cooling tank and stir for 1h to 2h to cool to 70°C to 80°C ℃; (4) Squeeze treatment: finely crush and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com