Surface processing copper foil

A surface treatment, copper foil technology, applied in the direction of electronic equipment, applications, household appliances, etc., can solve the problem of inability to obtain adhesion, and achieve the effect of improved adhesion and excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] On the M side of the electrolytic copper foil, it is plated for 8 seconds within the condition range of condition 1 to form a nickel film (first layer), and then plated for 10 seconds under the condition range of condition 4 to allow molybdenum to adhere (second layer). layer), then attach the anti-rust metal Zn·Cr, and then perform silane treatment.

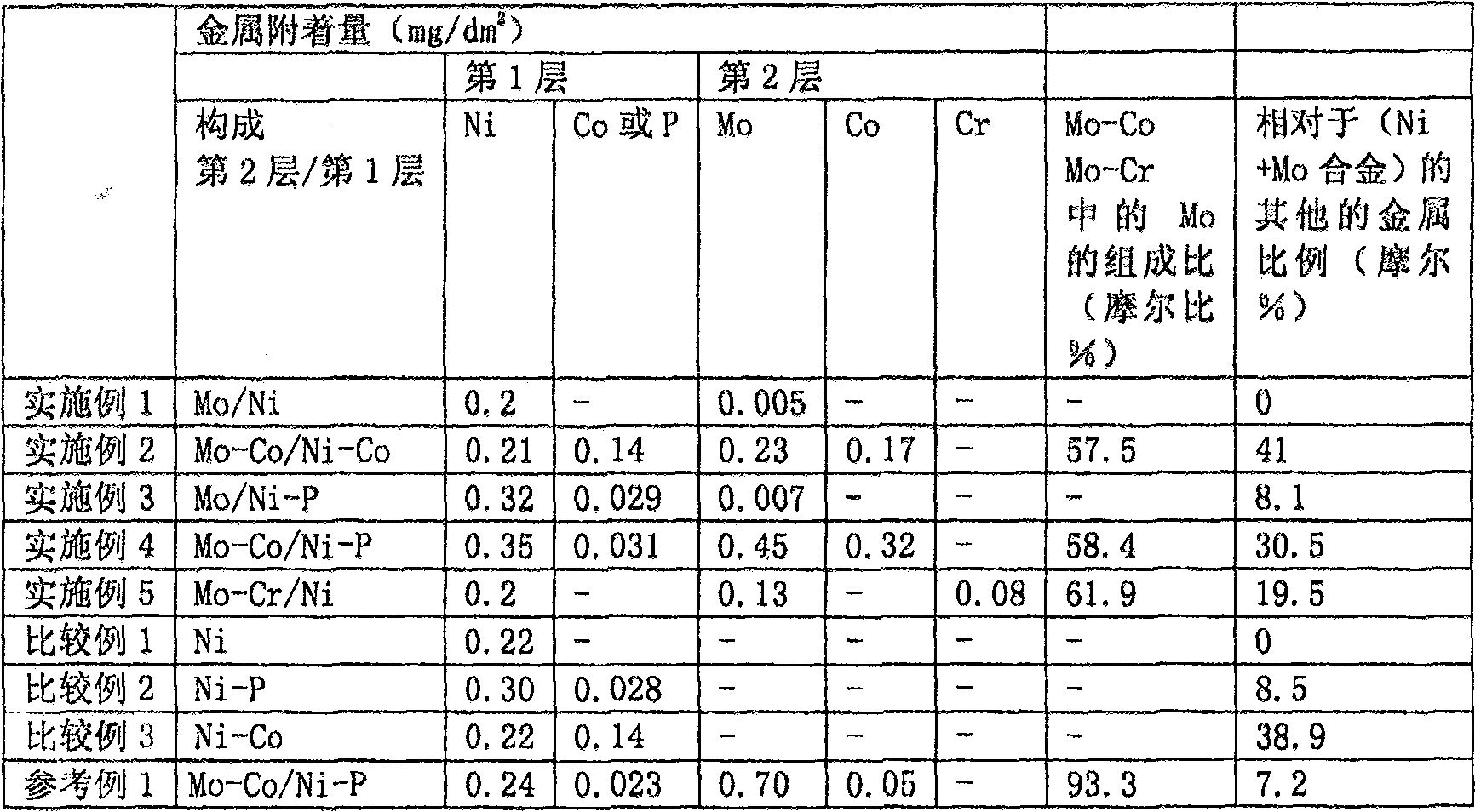

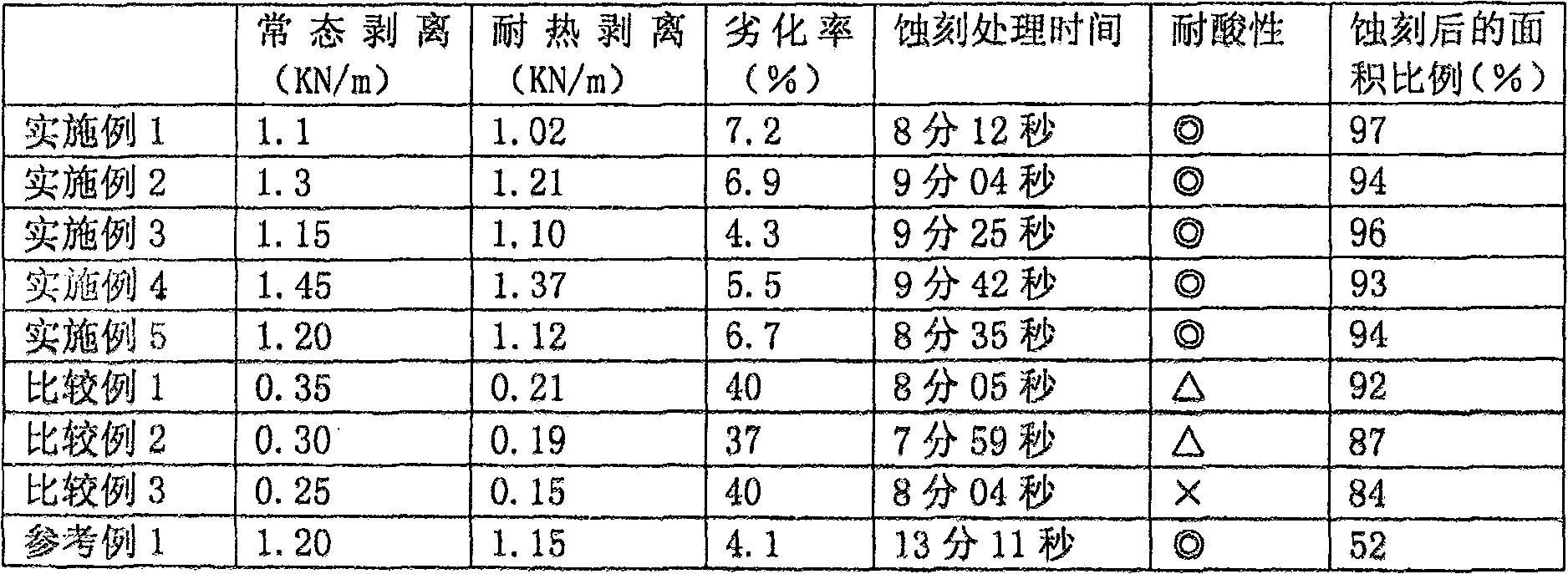

[0084] Table 1 shows the deposition amount of each metal deposited on the copper foil surface.

Embodiment 2

[0086] On the M surface of the electrolytic copper foil, it is plated under the condition range of condition 2 for 15 seconds to form a nickel-cobalt layer, and then plated thereon for 8 seconds under the condition range of condition 5 to adhere the molybdenum-cobalt alloy, and then apply The anti-rust metal Zn·Cr is attached, followed by silane treatment.

[0087] Table 1 shows the deposition amount of each metal deposited on the copper foil surface. At this time, cobalt was 23 mol % with respect to the total metal amount of nickel-cobalt and molybdenum-cobalt.

Embodiment 3

[0089] On the M surface of the electrolytic copper foil, a nickel layer containing phosphorus is formed by plating for 12 seconds under the condition range of condition 3, and a molybdenum layer is formed by plating for 14 seconds under the condition range of condition 4, and the anti- Rust metal Zn·Cr is attached, and then silane treatment is performed.

[0090] Table 1 shows the deposition amount of each metal deposited on the copper foil surface. At this time, phosphorus was 4 mol% with respect to the total metal amount of nickel metal and molybdenum metal containing phosphorus.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com