Method for purifying acetyl citrate

A technology of acetyl citrate and purification method, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high acid value, increased pressure on environmental protection treatment of waste water, and increased odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5-8

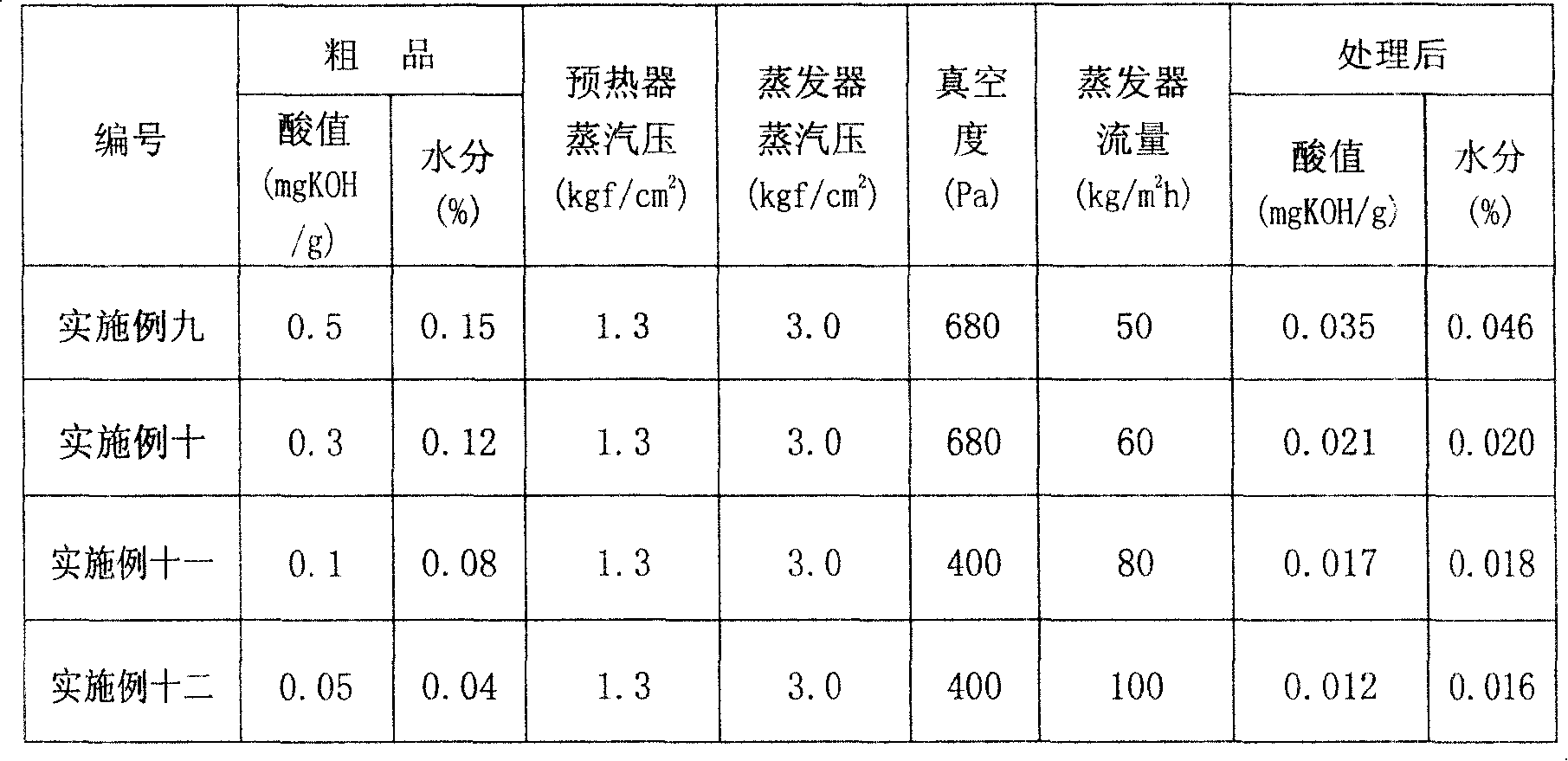

[0017] Embodiment 5-8, with acid number 0.082mgKOH / g, moisture is the ATBC crude product of 0.054% as example, when it is heated with steam 6m 2 When the rotary movable scraper type thin film evaporator is used, the steam pressure, vacuum degree and flow rate of the preheater and evaporator are controlled, and the results are as follows:

[0018]

Preheater

(kgf / cm 2 )

(kgf / cm 2 )

Vacuum

(Pa)

flow

(kg / m 2 h)

acid value

(mgKOH / g

)

Moisture (%)

Embodiment five

0.5

2.0

100

200

0.038

0.045

Embodiment six

1

3.0

400

100

0.009

0.018

Embodiment seven

1.3

3.5

680

50

0.008

0.016

Embodiment eight

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com