Energy-saving method for processing leachate of middle-aged or old refuse landfill

A technology for a landfill and a treatment method, applied in the field of landfill leachate wastewater treatment, can solve the problems of refractory ammonia nitrogen degradation and difficult removal of COD, and achieve high treatment efficiency, reduced operating costs, denitrification rate and COD removal rate. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

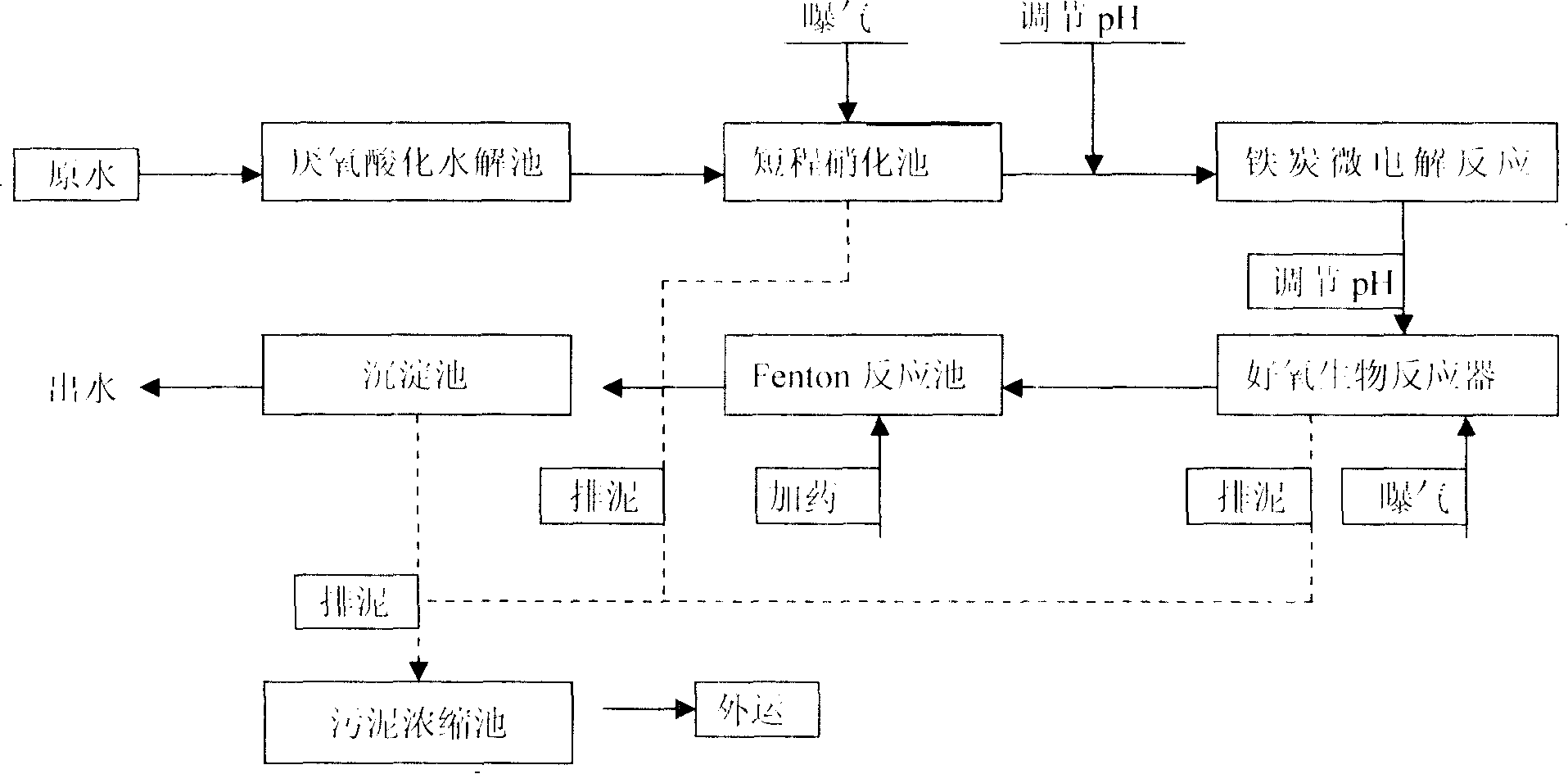

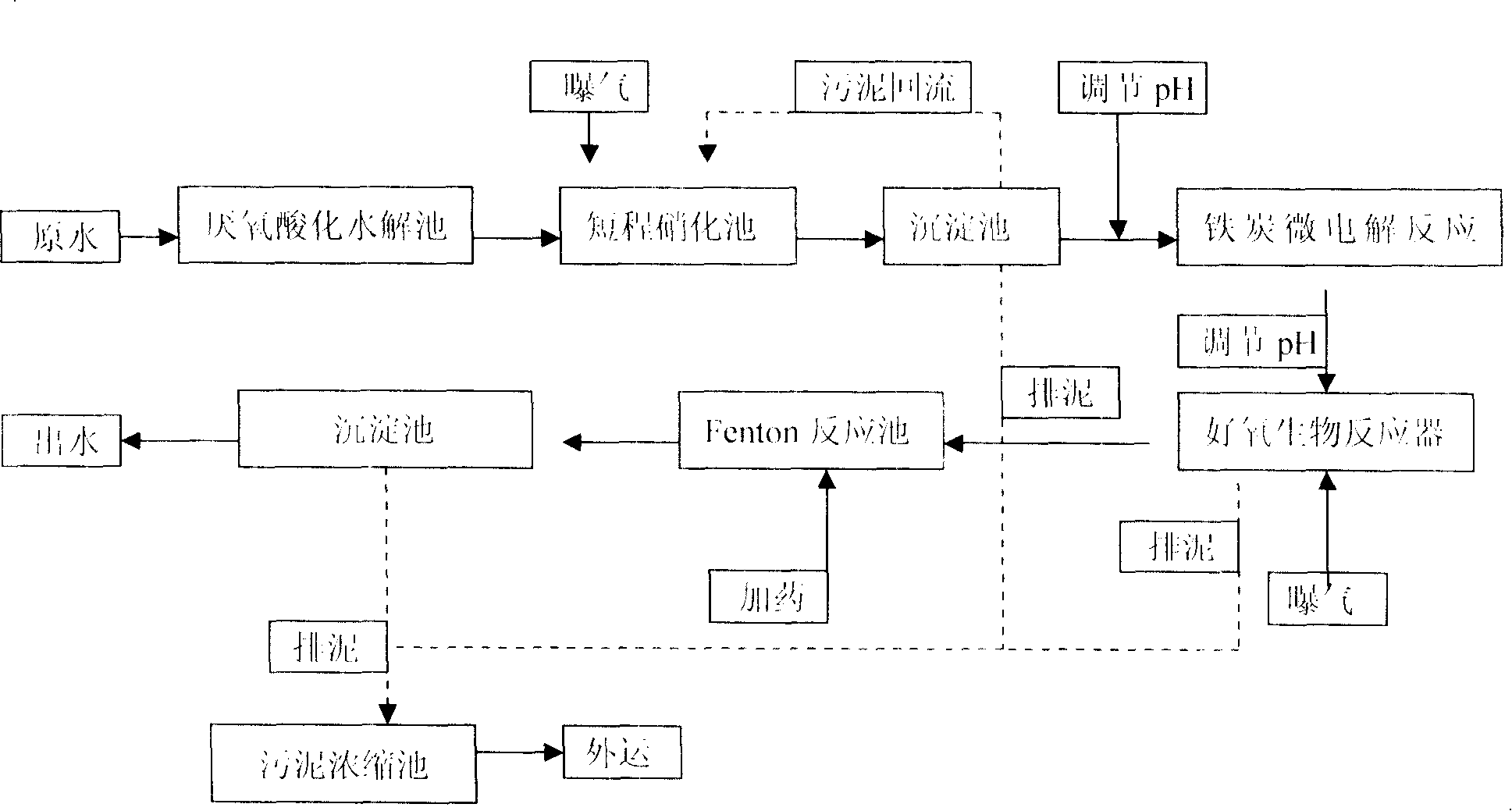

[0007] A new process for energy-saving middle-aged and elderly landfill leachate treatment, which includes primary biochemical treatment, primary physical and chemical treatment, secondary biochemical treatment, and secondary physical and chemical treatment.

[0008] In the primary biochemical treatment stage, the anaerobic hydrolytic acidification tank controls the wastewater in the hydrolytic acidification stage and completely converts Kjeldahl nitrogen into ammonia nitrogen. The temperature in the anaerobic hydrolytic acidification biological reaction tank is controlled at 20-30 °C, and the pH value is 7.5-9. The DO is controlled at figure 1 Filler film as shown or as figure 2 The suspended sludge shown operates in two ways.

[0009] The pH value of the wastewater needs to be adjusted to 1-2.5 before the first-level physicochemical process, the mass ratio of iron to carbon in the reactor is 1:1, the hydraulic retention time of the wastewater in the reactor is 0.5-1 hour, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com