Diamond soldering appliance

A diamond and brazing technology, used in stone processing tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reduced cutting efficiency, short tool life, low abrasive utilization rate, etc., and achieves reduced contact area and high processing efficiency. , the effect of long tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

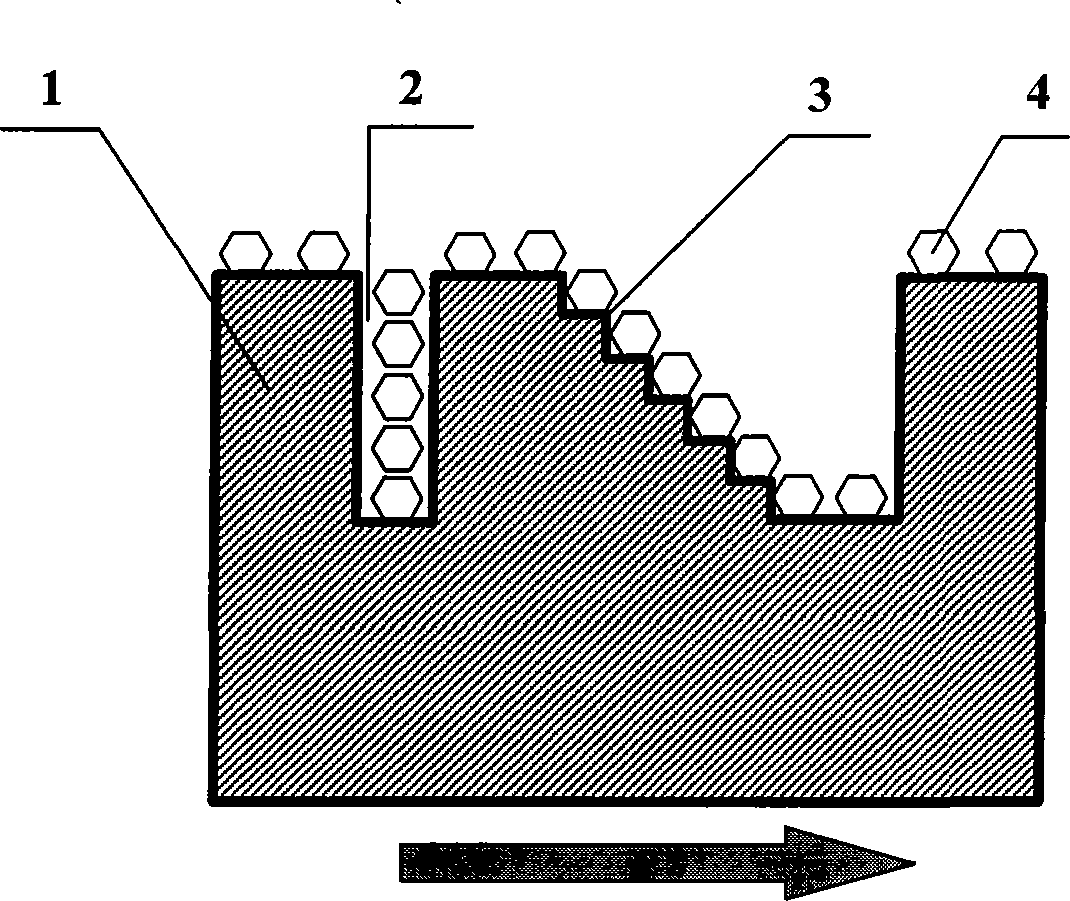

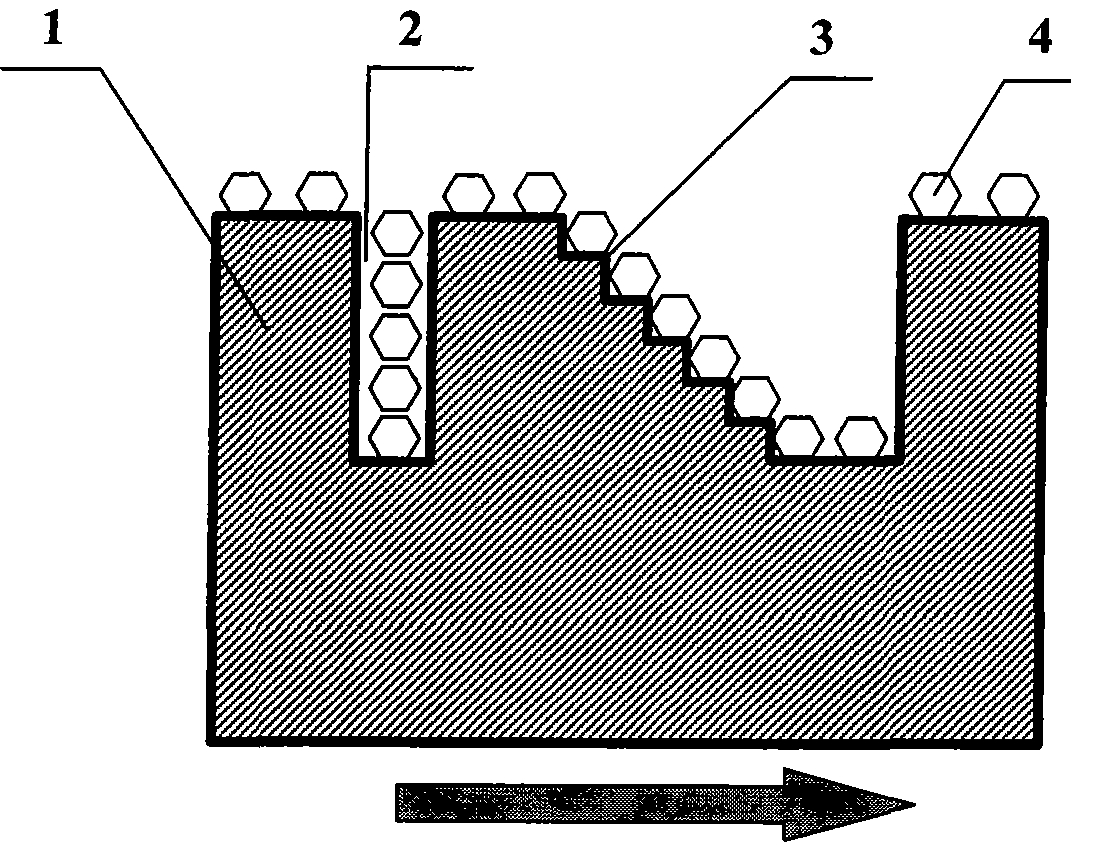

[0012] As shown in the figure, the diamond brazing tool with a combined structure of seams and stair-like steps includes a drill bit, a saw blade, and a grinding wheel. , The diamond abrasive material 4 is brazed and fixed on the step surface. The number of slots and stair-like steps depends on the diameter of the drill, saw blade, and grinding wheel, the processing object, and processing conditions. The depth of the combination of slots and stair-like steps depends on the life requirements of the drill, saw blade, and grinding wheel. The strength is determined, the width of the slit is determined by the number of columns containing diamond abrasives and the diameter of diamond abrasives, it can accommodate one column of diamond abrasives, or two or more columns, and the height and width of a single step are 60%-90% of the diamond particle size scale %. When working, the diamond abrasive is brazed in the seam and on the step surface, and the diamond abrasive is used step by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com