Developer roll and method of producing the same

A technology for developing rollers and metal shafts, which is applied to equipment, coatings, instruments, etc. in the electrical recording process using charge patterns, which can solve problems such as insufficient electrical conductivity, reduced surface roughness of developing rollers, oozing pollution, etc., and achieve product Uniform resistivity, less contamination of the photosensitive drum, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

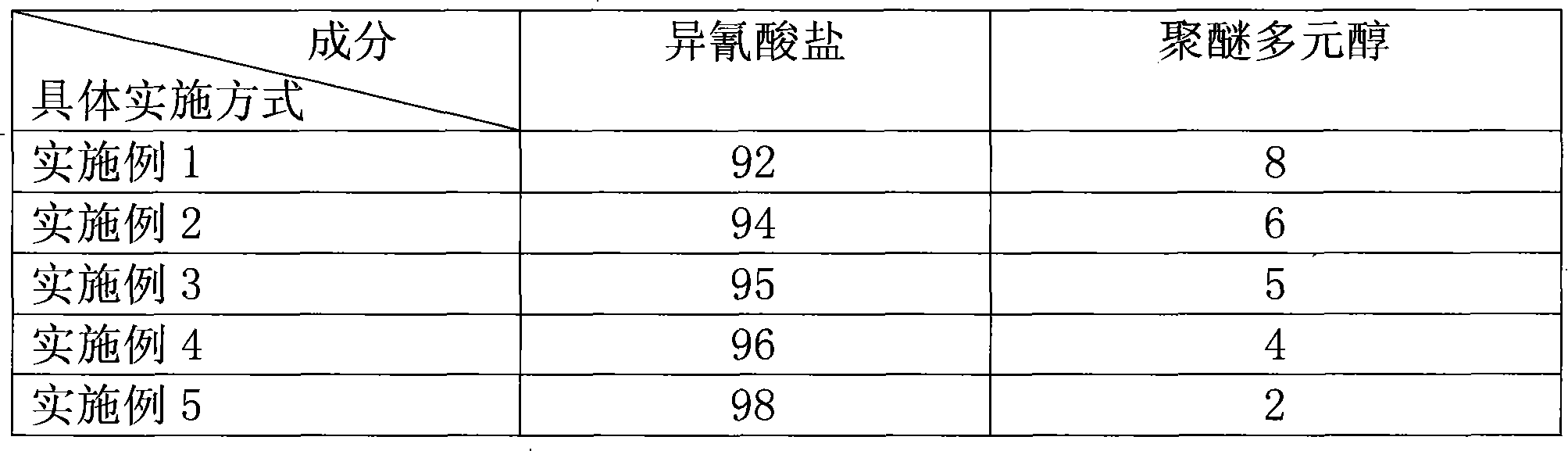

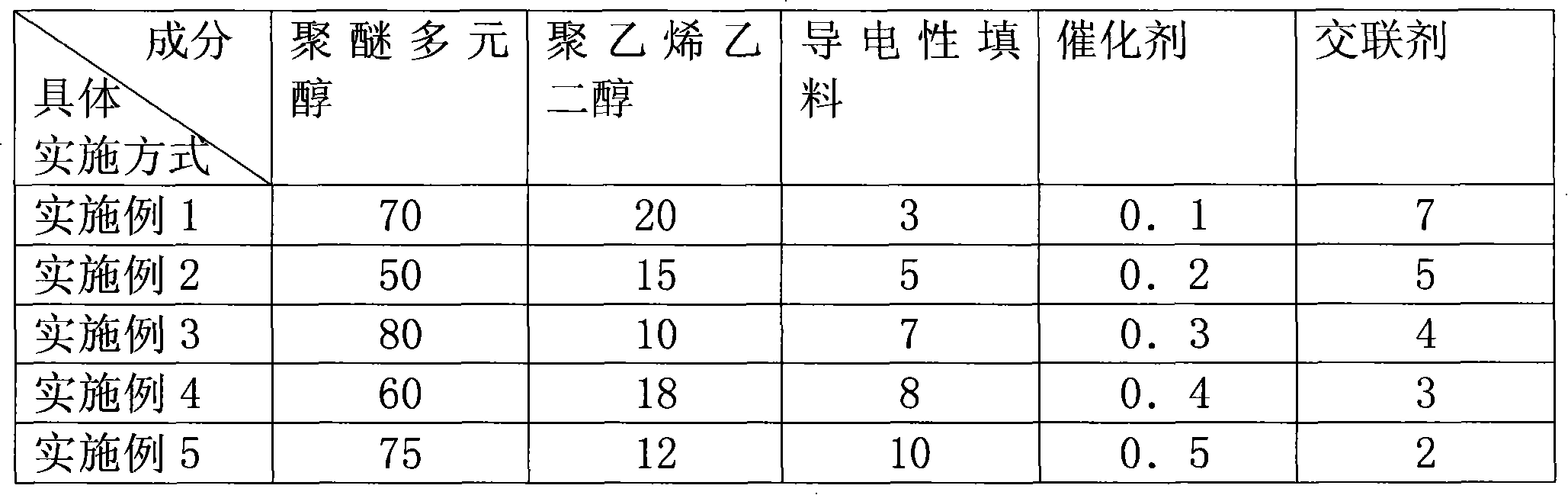

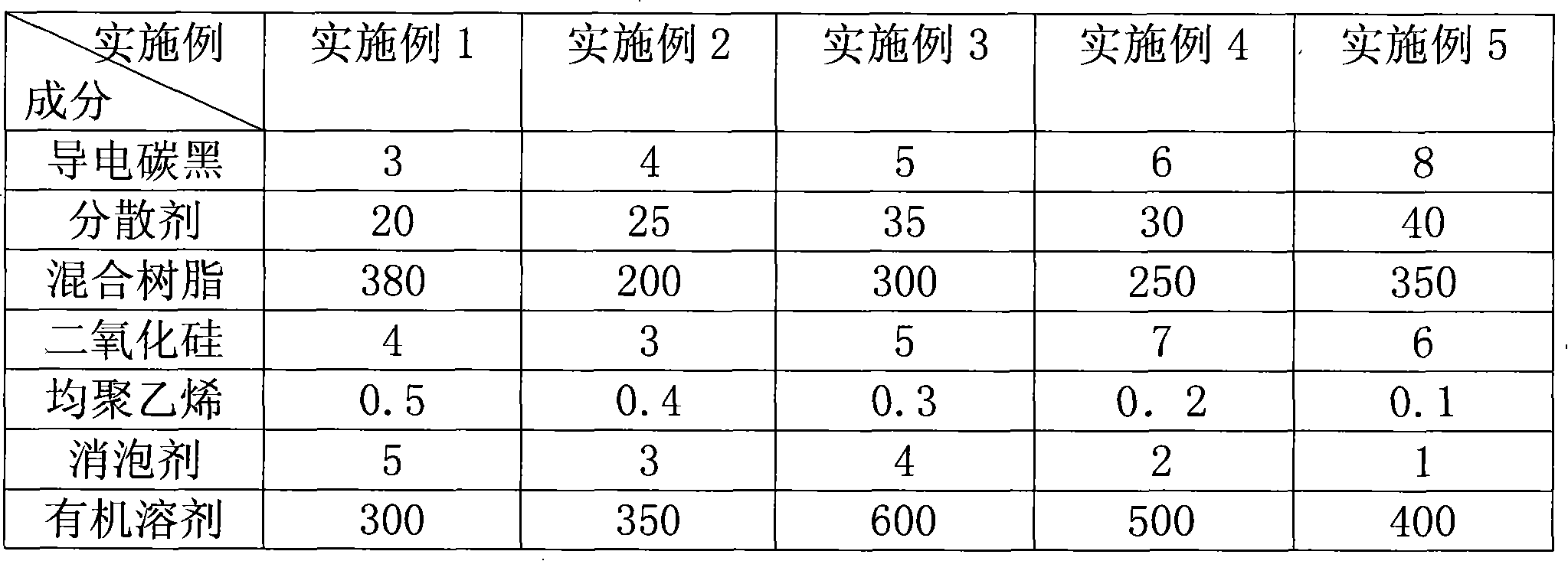

Method used

Image

Examples

Embodiment 2

[0049] Dispersant described in embodiment 2 is by weight percentage and is acrylic acid copolymer: 35%; Propylene glycol methyl ether acetate: 40%; Ethylene glycol butyl ether: 25% make; Described mixed resin is made of Acrylic resin by weight percentage: 65%; Isobutyl alcohol: 8%; Methyl isobutyl ketone: 7%; the rest is made of xylene; the defoamer is polymerized by weight percentage Ethyl glycolate: 8%; Ethyl glycol butyl ether: 1.5%; the rest is made of solvent gasoline; the organic solvent is acetone;

Embodiment 3

[0050] Dispersant described in embodiment 3 is by weight percent acrylic acid copolymer: 40%; Propylene glycol methyl ether acetate: 25%; Ethylene glycol butyl ether: 35% make; Described mixed resin is made of Acrylic resin by weight percentage: 70%; Isobutyl alcohol: 7%; Methyl isobutyl ketone: 8%; the rest is made of heavy aromatics; the defoamer is polymerized by weight percentage Ethyl glycolate: 7%; Ethyl glycol butyl ether: 1%; the rest is made of solvent gasoline; the organic solvent is butanone;

Embodiment 4

[0051] Dispersant described in embodiment 4 is by weight percent acrylic acid copolymer: 45%; Propylene glycol methyl ether acetate: 30%; Ethylene glycol butyl ether: 25% make; Described mixed resin is made of Acrylic resin by weight percentage: 75%; Isobutyl alcohol: 10%; Methyl isobutyl ketone: 5%; The rest is the mixing of toluene and xylene; Silicone resin polymer: 25%; ethyl glycolate: 6%; butyl glycol ether: 1%; the rest is made of solvent gasoline; the organic solvent is acetone;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com