Electron beam heating evaporation method as well as device and uses thereof

An electron beam heating and evaporating device technology, which is applied in vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve the problems of sophisticated power control system, high investment cost, and high operating technical requirements. Achieve the effect of excellent charge transport performance, simple equipment operation, and dense film material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

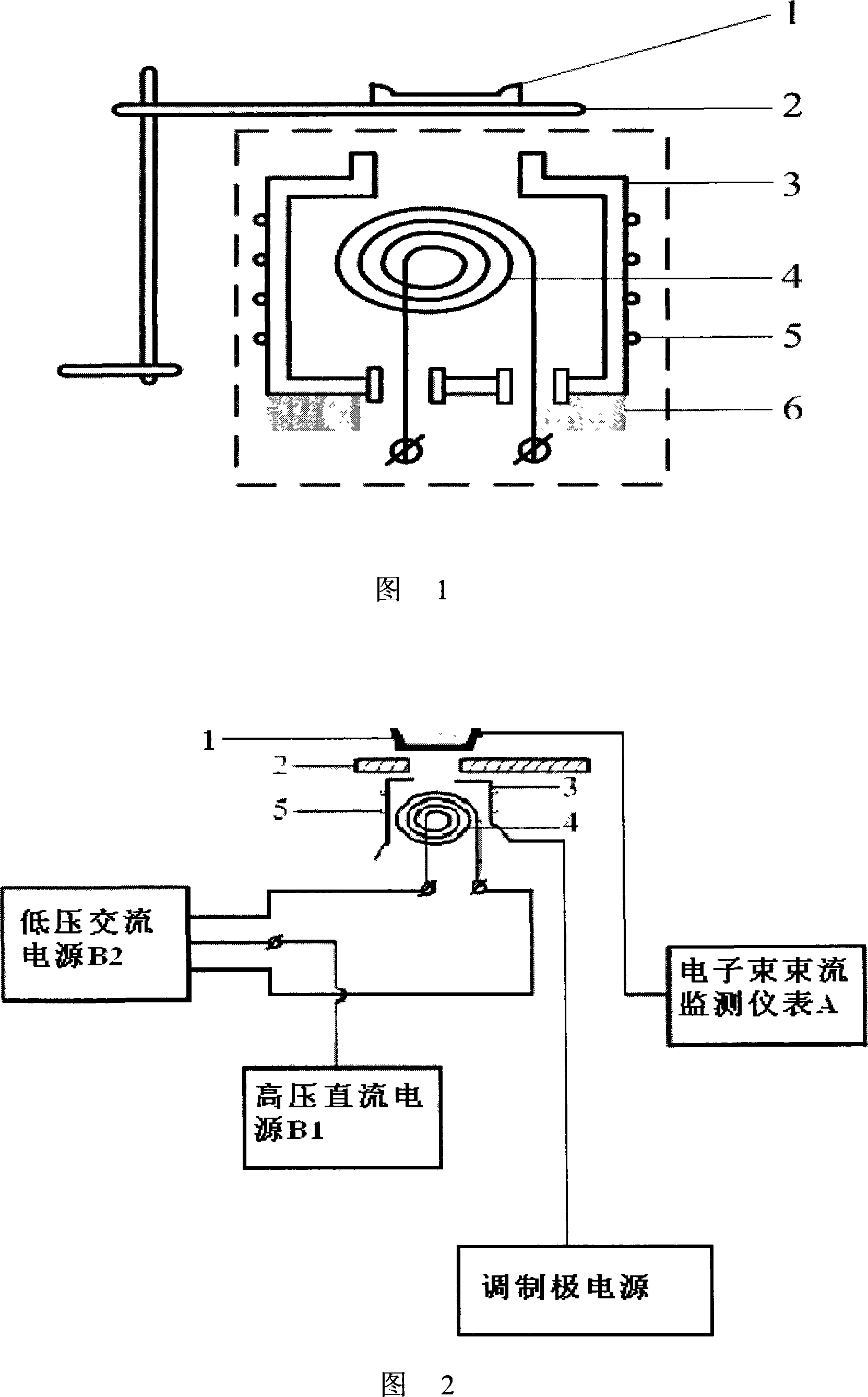

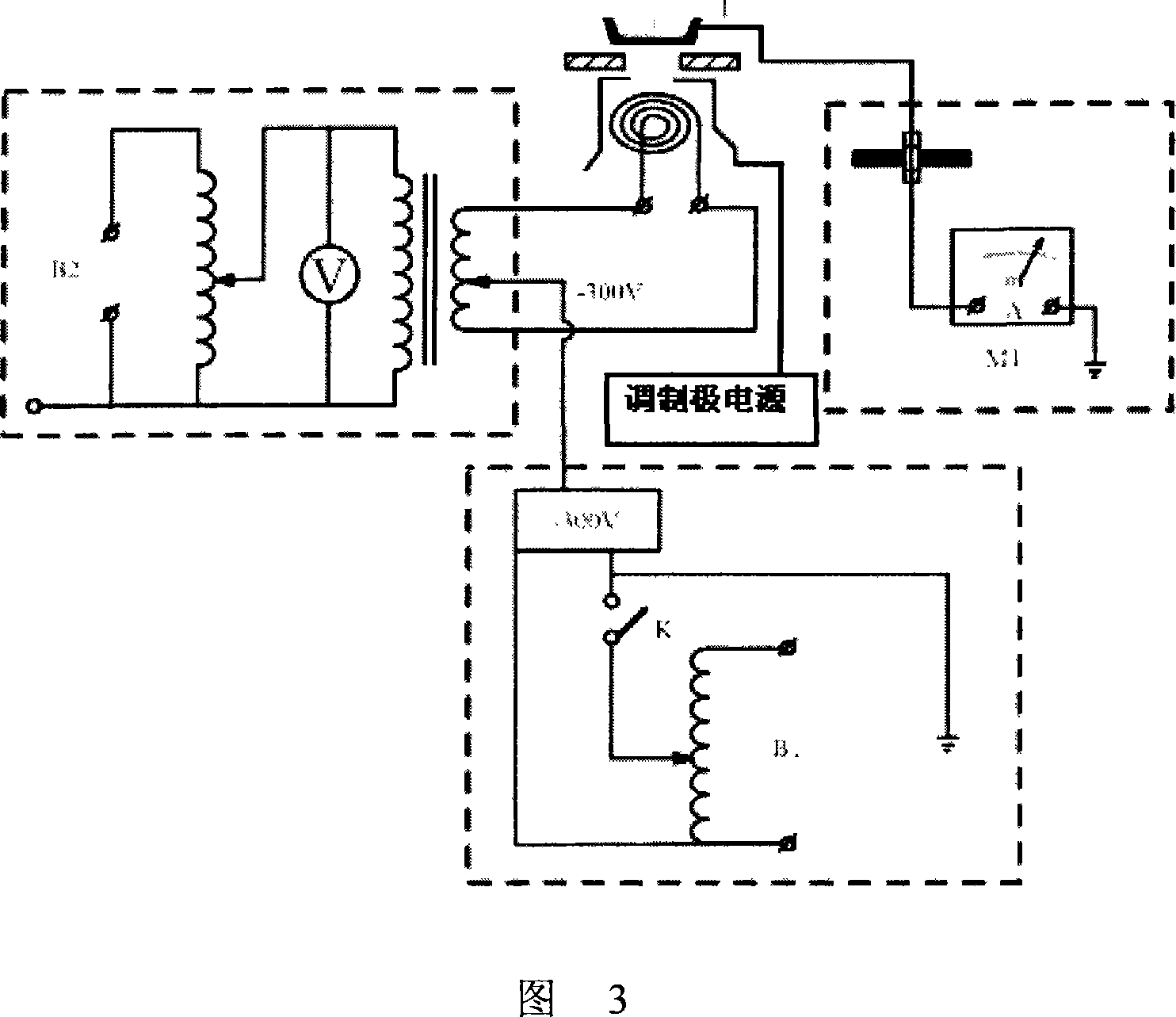

[0013] The electron beam heating evaporation method of the present invention combines two evaporation methods of electron beam heating evaporation and resistance heating evaporation, and a conventional high-voltage DC power supply provides a negative bias voltage for the hot cathode of the filament to form a strong electric field between it and the grounded crucible. In addition, a conventional low-voltage AC power supply provides an adjustable operating current for the filament hot cathode, and the heated filament hot cathode is used to emit electron beams. The electric field between the modulating electrode and the hot cathode of the filament is used to control the current size of the electron beam emitted by the hot cathode of the filament. Under the action of a strong electric field, the electron beam bombards the crucible at high speed and heats the crucible to evaporate different coating materials.

[0014] In the present invention, the modulator potential is generally s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com