Production method for oxide luminescent layer in inorganic electroluminescence display device

A production method and oxide technology, applied in electroluminescence light source, electric light source, light source and other directions, can solve the problems of high target production cost, difficult composition adjustment, long cycle, etc., saving time and material cost, composition adjustment Easy, short cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix manganese-doped zinc silicate (green fluorescent powder), zinc oxide (purity 99.99%), germanium oxide (purity 99.999%), and manganese oxide (purity 99.99%) according to the molar ratio of 1:1.92:1:0.08. , sprayed onto the oxygen-free copper backplane with argon plasma, and the thickness of the green ceramic target was 1 mm after spraying.

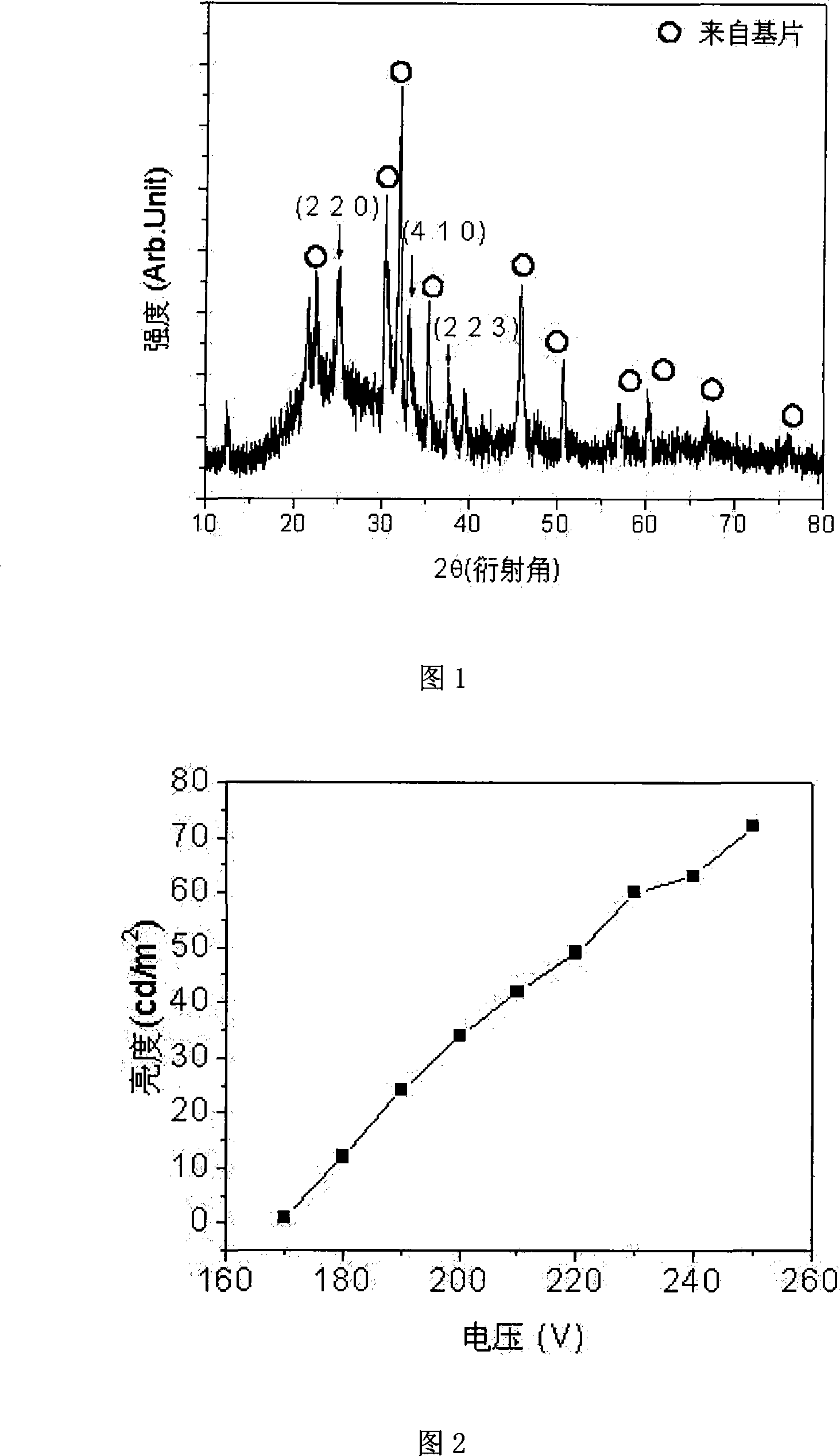

[0031] A lower dielectric layer, barium strontium titanate, is sputter deposited on the transparent lower electrode ITO on the TFT-LCD glass substrate, with a thickness of 300 nanometers. Then, a 400-nm green EL emitting layer was sputtered on the lower dielectric layer of barium strontium titanate with the spraying target made by the above method. The sputtering condition of the light-emitting layer is: the background vacuum is 2.7×10 -3 Pa, Ar / O 2 The ratio is 9:1, the sputtering pressure is 0.1Pa, the substrate temperature is 200°C, the target base distance is 5cm, and the sputtering power density is 8.8W / cm 2 . After sput...

Embodiment 2

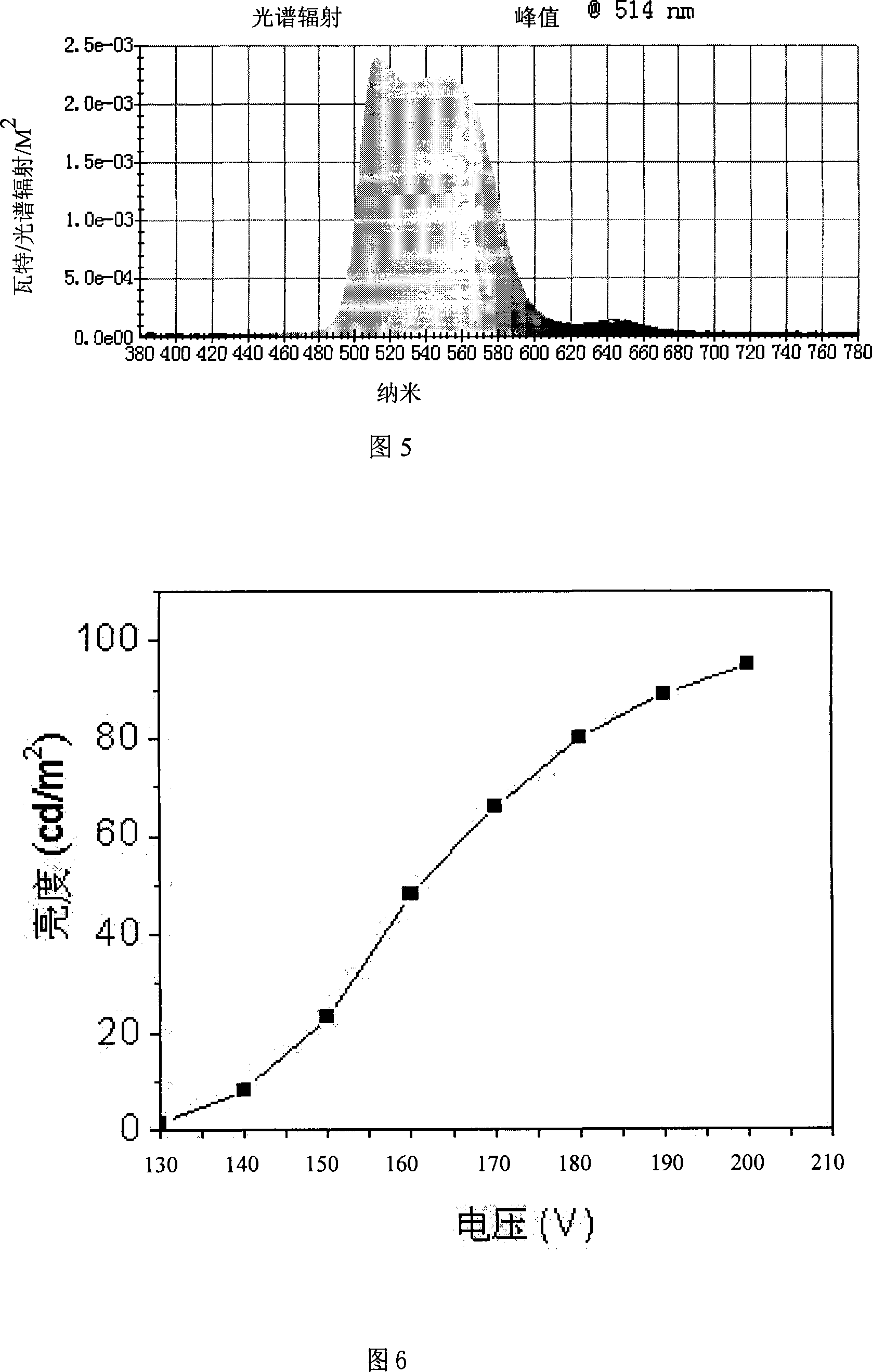

[0033] The preparation method of the spraying target is the same as that of Example 1, but before spraying, the green light powder is mixed evenly and then pre-sintered in the air at 1200°C for 4 hours. This is to make each component react and make it more uniform and stable. . The structure of the fabricated green EL device is the same as that in Example 1. The thickness of the light-emitting layer is 400 nanometers, and the sputtering condition: the background vacuum is 2.7×10 -3 Pa, Ar / O 2 The ratio is 9:1, the sputtering pressure is 2Pa, the substrate temperature is 200°C, the target base distance is 5cm, and the sputtering power density is 8.8W / cm 2 . Annealing is carried out after sputter coating, and the annealing conditions are the same as in Example 1. What Fig. 4 shows is the luminance-voltage curve of this green light EL device, test condition is identical with embodiment 1, what Fig. 5 shows is this green light EL device when applying the electroluminescence sp...

Embodiment 3

[0035] The preparation method of the spraying target is the same as that of Example 2, and the structure of the fabricated green light device and the sputtering conditions of the light-emitting layer are the same as those of Example 2. The luminescent layer was annealed in a vacuum annealing furnace at 700°C for one hour, and oxygen was introduced to 1.2*10 during the annealing process. -2 Pa. What Fig. 6 shows is the luminance-voltage curve of this green light EL device, and test condition is identical with embodiment 1, and what Fig. 7 shows is this green light EL device when applying 200V AC pulse voltage, and the corresponding color coordinates are (x=0.428, y=0.550).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com