Plasticizing and modifying method for polylactic acid

A technology of toughening modification and toughening modifier, which is applied in the field of polylactic acid and polylactic acid blending modification, can solve the problems of the influence of the biodegradation performance of the mixture, the low utilization rate of renewable materials, and the reduction of practical use significance. , to achieve the effect of significant toughening effect, wide range of options, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation of copolyester

[0020] Using PET industrial equipment, during the esterification reaction or polycondensation reaction of terephthalic acid and ethylene glycol monomers,

[0021] (1) Add a mixture of isophthalic acid, hexamethylenediamine, 1,4-cyclohexanedimethanol, and polyethylene glycol with a number average molecular weight of 200 to 4000 as a modification additive, and add it to the reaction system to generate 1 # Modified copolyester;

[0022] (2) Add an appropriate amount of 1,4 cyclohexanedimethanol to obtain 2 # Modified copolyester;

[0023] (3) still use 1,4 cyclohexane dimethanol as the third monomer, change the addition amount, obtain 3 # Modified copolyester;

[0024] (4) Add a mixture of isophthalic acid, 1,4-cyclohexanedimethanol, and polyethylene glycol with a number average molecular weight of 200 to 4,000 as a modification additive, and add it to the reaction system to generate 4 # Modified copolyester.

[0025] 1 ...

Embodiment 2

[0028] Embodiment 2: blank test

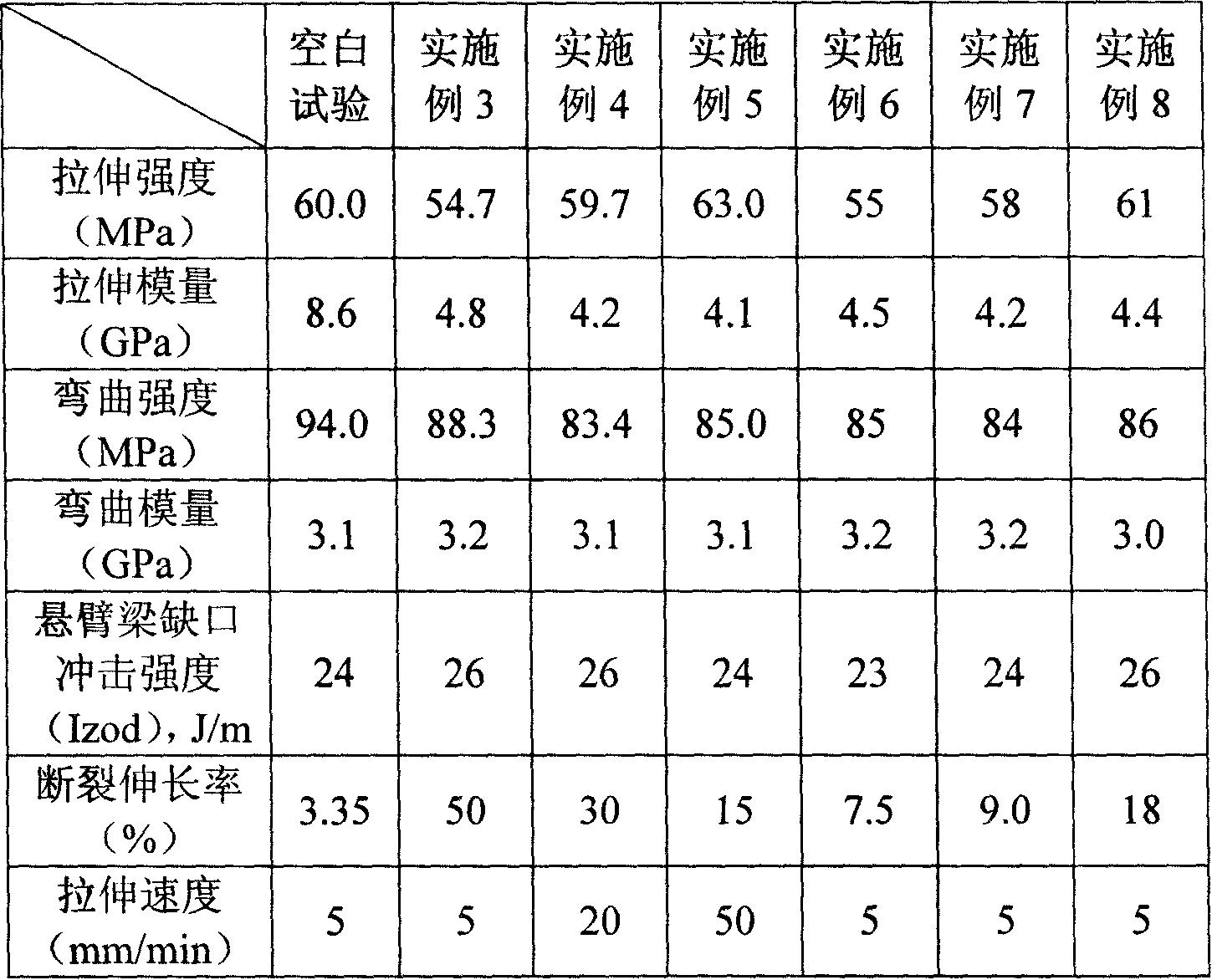

[0029] 2500g of polylactic acid resin (trade name: NatureWorks PLA 2002D, the same below) was dried at 90-110°C for 6 hours, so that the moisture content was lower than 50ppm, and melted and extruded by a screw extruder and injected to obtain a test sample. Test its tensile properties, bending properties and impact strength. The test results are shown in Table 2.

Embodiment 3

[0030] Example 3: 1 # Copolyester Toughened PLA (Part 1)

[0031] With 2475g polylactic acid resin and 25g copolyester (1 # ) were uniformly mixed with a high-speed mixer, dried at 90-110°C for 6 hours, so that the moisture content was lower than 50ppm, melted and extruded by a screw extruder and injected to obtain a test sample, and its tensile and bending properties were tested and impact strength.

[0032] The test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com