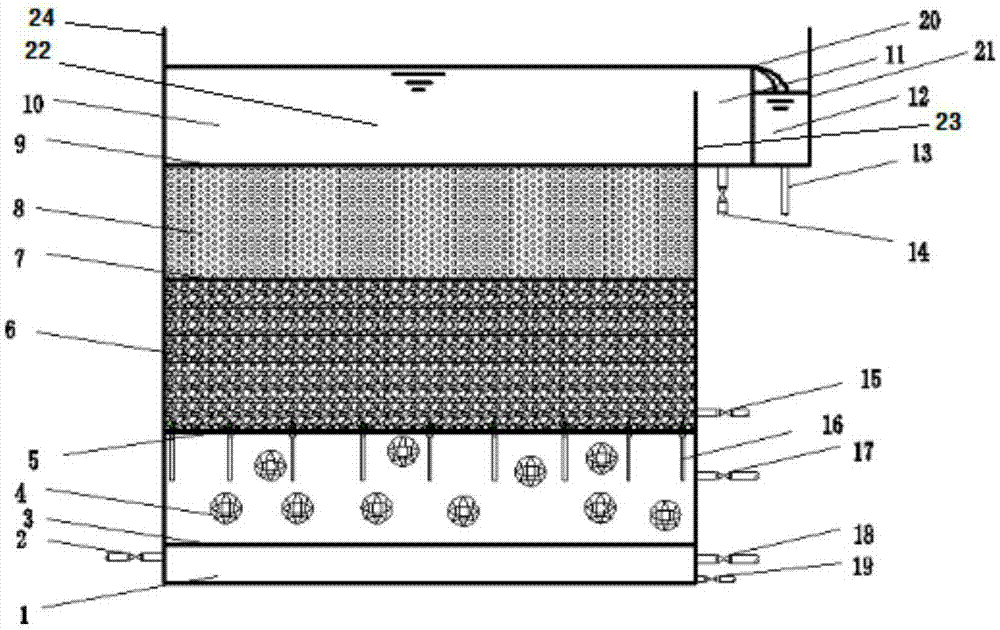

Multi-medium biological aerated filter and method for treating traditional Chinese medicine decoction piece wastewater using same

A biological aerated filter and multi-media technology, applied in the field of water treatment, can solve problems such as difficult promotion, poor effect, substandard chroma, etc., to ensure the effect of biochemical treatment, prevent excessive loss of water head, and reduce pollutants load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A Chinese medicine decoction piece pharmaceutical factory in Jiangsu, which mainly produces hundreds of Chinese medicine decoction pieces such as Codonopsis, Salvia, Angelica, Gastrodia, Astragalus, Licorice, Chuanbei, etc. The discharge amount of production wastewater is 230m 3 / d—470m 3 / d, CODcr 357mg / L-2879mg / L in wastewater, BOD 5 Concentration 69mg / L-946mg / L, SS80mg / L-833mg / L, ammonia nitrogen 6.2mg / L-27mg / L, pH6.5-8.0.

[0064] The wastewater treatment process of the present invention is used for treatment, and the discharge volume is an average of 370m 3 / d, average CODcr in wastewater 725mg / L, BOD 5 The average concentration is 169mg / L, the average SS is 433mg / L, the average ammonia nitrogen is 17mg / L, and the pH is 6.5-8.0. First, it enters the middle grid to remove large suspended solids, and the grid slag is transported to the sludge thickening tank. The effluent enters the cyclone grit tank at a flow rate of 0.7m / s to remove gravel and inorganic salt particles. ...

Embodiment 2

[0070] A Chinese medicine decoction piece pharmaceutical factory, the average CODcr in the wastewater produced by the factory is 1870mg / L, BOD 5 The average concentration is 367mg / L, the average SS is 698mg / L, the average ammonia nitrogen is 20mg / L, and the pH is 8.0-9.0.

[0071] The wastewater treatment process of the present invention is used for treatment, and the production wastewater first enters the middle grille to remove large suspended solids. The effluent enters the cyclone grit chamber at a flow rate of 0.6m / s to remove gravel and inorganic salt particles. The hydraulic retention time is 39.2s. The sand is lifted every 2 days and the sand is transported to the sludge thickening tank. The effluent enters the vortex air flotation tank, firstly adjust the pH to 7.0 with hydrochloric acid, then add 40mg / L PAC, then add 10mg / L PAM, and the scum is transported to the sludge conveying pipe by the slag scraper. After the effluent enters the hydrolysis acidification tank, the ...

Embodiment 3

[0077] A Chinese medicine decoction piece pharmaceutical factory, the factory has an average production wastewater flow of 782m3 / d, an average wastewater CODcr of 2000mg / L, BOD 5 The average concentration is 567mg / L, the average SS is 800mg / L, the average ammonia nitrogen is 15mg / L, and the pH is 6.0-7.2.

[0078] The wastewater treatment process of the present invention is used for treatment, the production wastewater first enters the coarse grid to remove large suspended solids, and then passes through the middle grid to remove a part of solids of 10-30 mm. The effluent enters the cyclone grit chamber to remove gravel and inorganic salt particles. The hydraulic retention time is 41.2s, and the sand is lifted every 2 days. The effluent enters the vortex air flotation tank, without adjusting the pH, directly adding 30mg / L of PAC, and then adding 15mg / L of PAM, and the scum is transported to the sludge conveying pipe by the slag scraper. After the effluent enters the hydrolysis ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com