Biodegradable material and preparation method thereof

A biodegradable material and biodegradable technology, applied in the field of biodegradable materials, can solve the problem that the mechanical performance index cannot be compared with non-biodegradable materials, the products of biodegradable materials cannot be promoted and mass produced, and the use value of biodegradable materials is limited. and other problems to achieve the effect of reducing water vapor transmission rate, improving affinity and compatibility, and enhancing processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

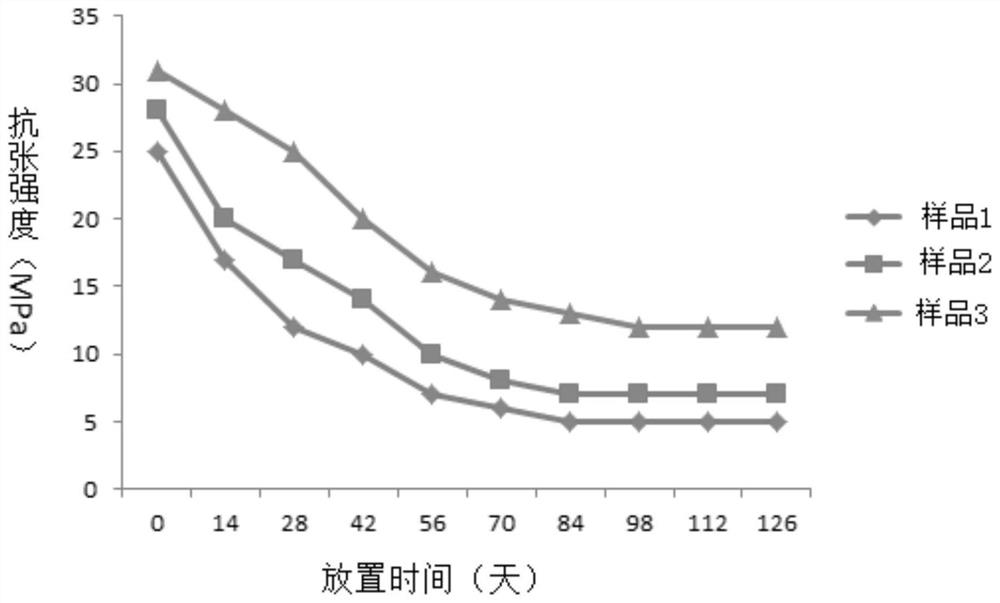

Embodiment 1

[0048] A kind of biodegradable material, comprises the raw material of following weight: bio-based resin 12g, bio-based filler 10g, modified nano calcium carbonate 4g, talcum powder 5g, glass fiber powder 5, zinc oxide powder 6g, plasticizer 5g, lubricant 1.2g, 0.7g of biodegradation accelerator, 10g of antistatic agent, 3g of epoxidized vegetable oil.

[0049] Wherein, the bio-based resin in this embodiment is composed of PLA and PBAT, and the mass ratio of PLA to PBAT is 1:1.

[0050] Wherein, the bio-based filler in this embodiment is potato starch.

[0051] Wherein, the particle diameter of the talc powder in this embodiment is 3000 mesh, the diameter of the glass fiber is 15 μm, and the particle diameter of the zinc oxide powder is 3000 mesh.

[0052] Wherein, the epoxidized vegetable oil in the present embodiment is epoxidized soybean oil. The epoxy value of epoxidized vegetable oil is 6.6.

[0053] Wherein, the lubricant in the present embodiment is stearic acid;

...

Embodiment 2

[0066] A kind of biodegradable material, comprises the raw material of following weight: bio-based resin 79g, bio-based filler 45g, modified nano calcium carbonate 19g, talcum powder 14g, glass fiber powder 10g, zinc oxide powder 12g, plasticizer 15g, lubricant 5g, 3.2g of biodegradation accelerator, 50g of antistatic agent, 15g of epoxidized vegetable oil.

[0067] Wherein, the bio-based resin in this embodiment is composed of PLA and PBAT, and the mass ratio of PLA to PBAT is 1:1-1.2.

[0068] Wherein, the bio-based filler in this embodiment is potato starch.

[0069] Wherein, the particle diameter of the talcum powder in the present embodiment is 3000 mesh, the diameter of glass fiber is 15 μ m, the particle diameter of zinc oxide powder is 3000 mesh

[0070] Wherein, the epoxidized vegetable oil in the present embodiment is epoxidized soybean oil;

[0071] Wherein, the lubricant in the present embodiment is oleic acid;

[0072] Wherein, the antistatic agent in this embo...

Embodiment 3

[0084] A kind of biodegradable material, comprises the raw material of following weight: bio-based resin 60g, bio-based filler 38g, modified nano-calcium carbonate 15g, talcum powder 15g, glass fiber powder 15g, zinc oxide powder 14g, plasticizer 10g, lubricant Agent 3g, biodegradation accelerator 3.6g, antistatic agent 29g, epoxidized vegetable oil 14g.

[0085]Wherein, the bio-based resin in this embodiment is composed of PLA and PBAT, and the mass ratio of PLA to PBAT is 1:1-1.5.

[0086] Wherein, the bio-based filler in this embodiment is potato starch.

[0087] Wherein, the particle diameter of the talcum powder in the present embodiment is 3000 mesh, the diameter of glass fiber is 15 μ m, the particle diameter of zinc oxide powder is 3000 mesh

[0088] Wherein, the epoxidized vegetable oil in the present embodiment is epoxidized soybean oil;

[0089] Wherein, the lubricant in the present embodiment is stearic acid;

[0090] Wherein, the antistatic agent in this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com