Hydrogenation catalysts carrier with nickel and cobalt, hydro-catalyst and its preparing method

A hydrogenation catalyst and catalyst technology, which are applied to catalyst carriers, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of reducing the specific surface area and pore volume of the catalyst, failing to give full play to the effect of titanium oxide, and having a low-activity nickel-aluminum spinel structure. and other problems, to avoid the decrease of specific surface area, avoid blockage and decrease of specific surface area, and improve the dispersion and vulcanization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

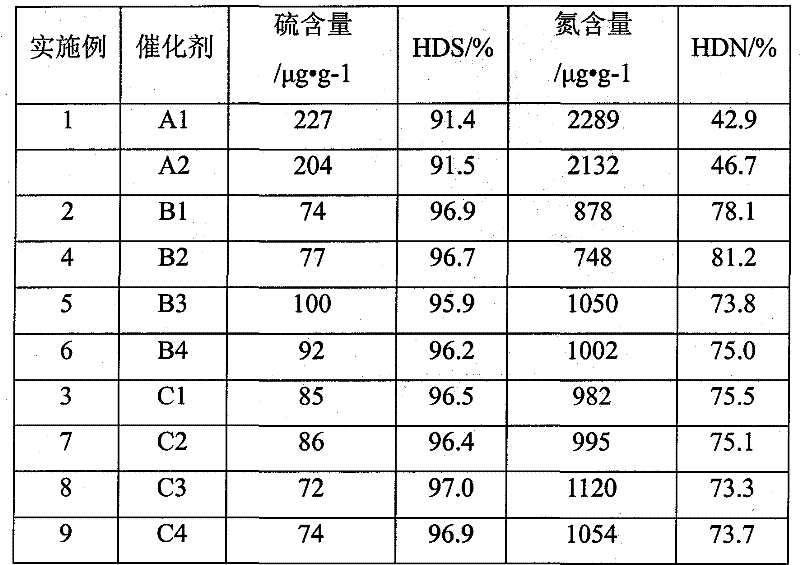

Examples

Embodiment 3

[0042] Dissolve 2g of nickel nitrate in 72ml of ethanol to obtain solution A; add 109.2g of tetrabutyl titanate and 16.8g of tetraethyl orthosilicate to solution A, and stir and disperse 3g of HY molecular sieves in solution A, evenly Mix to obtain solution B; mix 19ml of water, 41.2ml of acetic acid and 40ml of absolute ethanol to obtain solution C. Add solution C dropwise to B and stir for 10 to 30 minutes to obtain a sol, and the sol is aged for a certain period of time under natural conditions to obtain a gel; the gel drying and roasting conditions are the same as in Example 1, and a carrier material B containing 1% NiO is obtained. 1. The specific surface area, pore volume and pore diameter of the sample measured by BET method are SBET=321m2·g-1, V=0.72ml·g-1, D=9.0nm respectively.

Embodiment 4

[0044] 109.2g of tetrabutyl titanate and 16.8g of tetrabutyl titanate and 16.8g of ethyl orthosilicate were respectively dissolved in 72ml of ethanol to obtain solution A; 3g of HY molecular sieves were stirred and dispersed in solution A to obtain solution B; 2g of nickel nitrate was dissolved in Green solution C was obtained in 40ml of ethanol; solution D was obtained by mixing 19ml of water and 41.2ml of acetic acid with solution C. Put solution D dropwise into A and stir for 10-30 minutes to obtain a sol, and the sol is aged under natural conditions for a certain period of time to obtain a gel; the drying and roasting conditions of the gel are the same as in Example 1, and a carrier material C containing 1% NiO is obtained -1, the specific surface area, pore volume, and pore diameter of the sample measured by the BET method are: SBET=328m2·g-1, V=0.73ml·g-1, D=8.9nm.

Embodiment 5

[0046] Change the quality of the nickel nitrate in embodiment 2 into 4g, all the other steps and preparation conditions are constant, make the carrier B-2 that contains NiO 2%, adopt the method for BET to record the specific surface area and pore volume of this carrier material, The pore sizes are: SBET=321m2·g-1, V=0.71ml·g-1, D=8.5nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com