Method for manufacturing silicon microchannel plate secondary electron emission layer

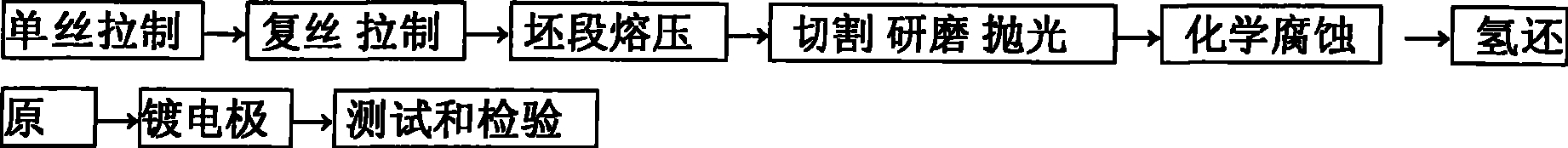

A secondary electron emission and silicon microchannel plate technology, which is applied in the manufacture of circuits, electrical components, and cold cathodes, can solve problems such as high technical requirements, expensive manufacturing equipment, and long preparation time, and achieve low technical difficulty and smooth process. Simple, short preparation time results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

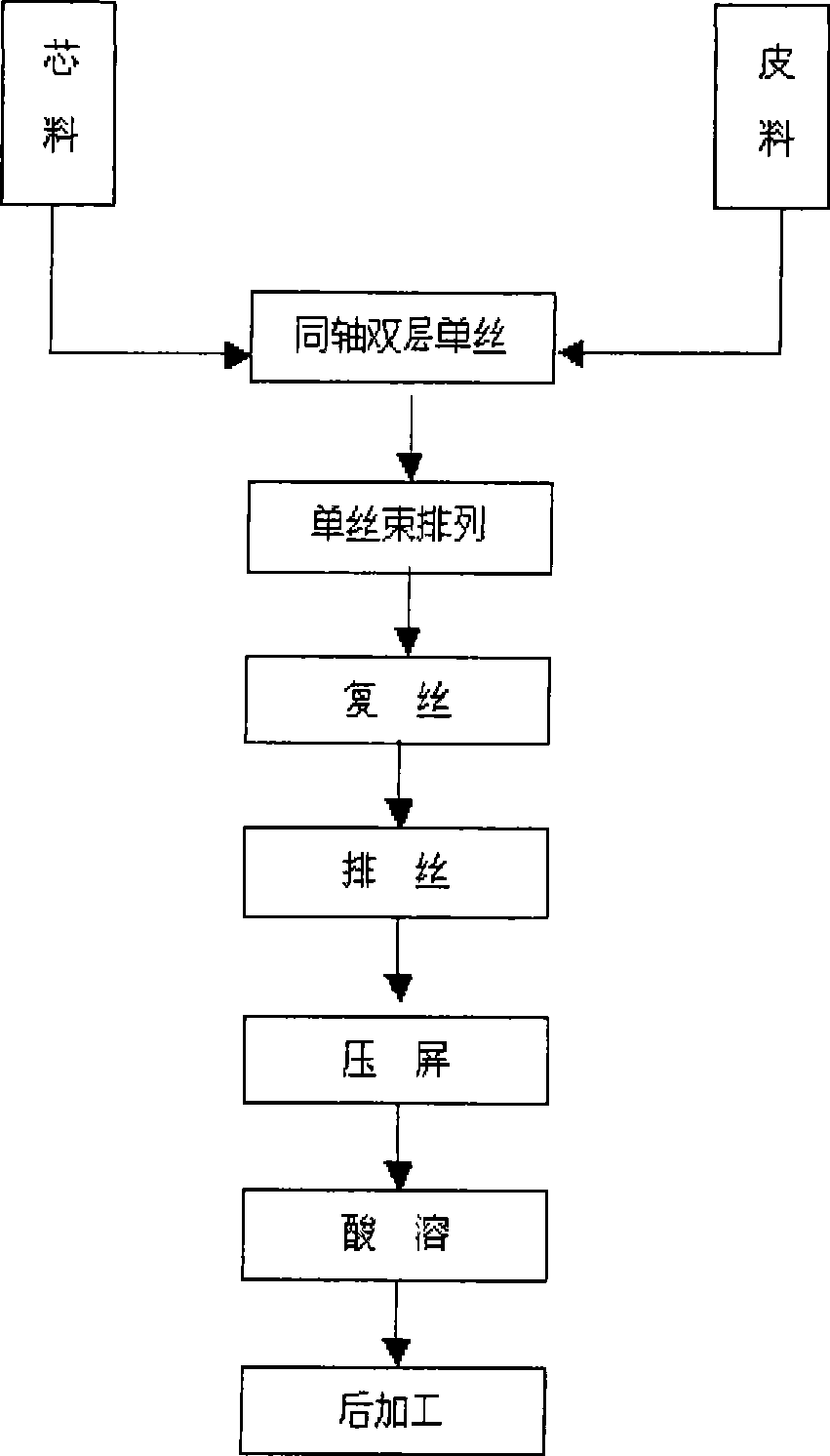

Method used

Image

Examples

Embodiment Construction

[0025] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

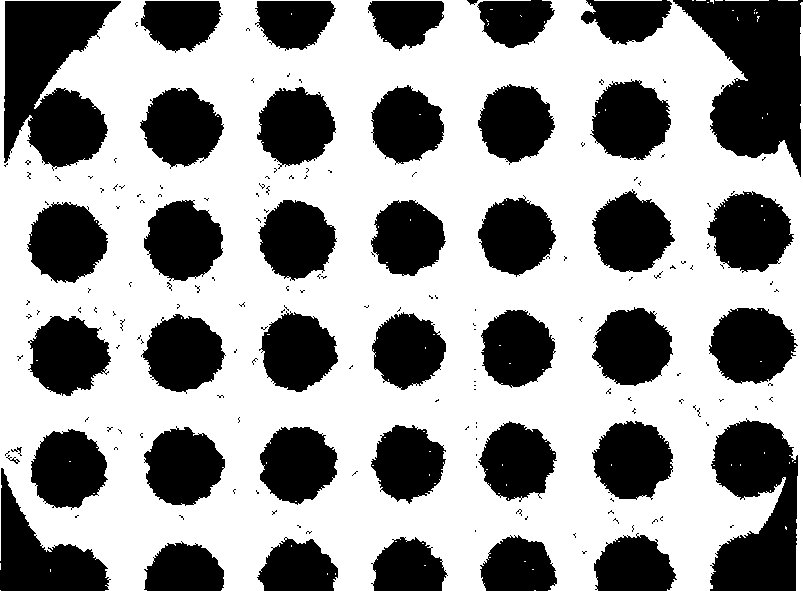

[0026] Considering that the MgO material has a high secondary electron emission coefficient, the secondary electron yield δ value is about 4.5, and the MgO material has good thermal stability, can be directly exposed to the atmosphere, and can be dissolved in a specific solvent No chemical reaction occurs; therefore, the present invention uses MgO as the secondary electron emission material. However, because the melting point of MgO is very high, usually at 3000°C, the conventional vacuum coating method cannot be used; the present invention utilizes the characteristics that MgO is soluble in glacial acetic acid and does not chemically react with glacial acetic acid, according to the ratio of about 1:30 Prepare MgO glacial acetic acid solution. After fully stirring and dissolving, the solution becomes transparent. Place the microchannel plate in the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com