Method for preparing functional film layer on channel inner wall of ultra-large aspect ratio microchannel plate

A micro-channel plate, aspect ratio technology, applied in the direction of coating, metal material coating process, electron multiplier details, etc., can solve problems such as failure to meet use requirements, limited improvement range, and reduced gain performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

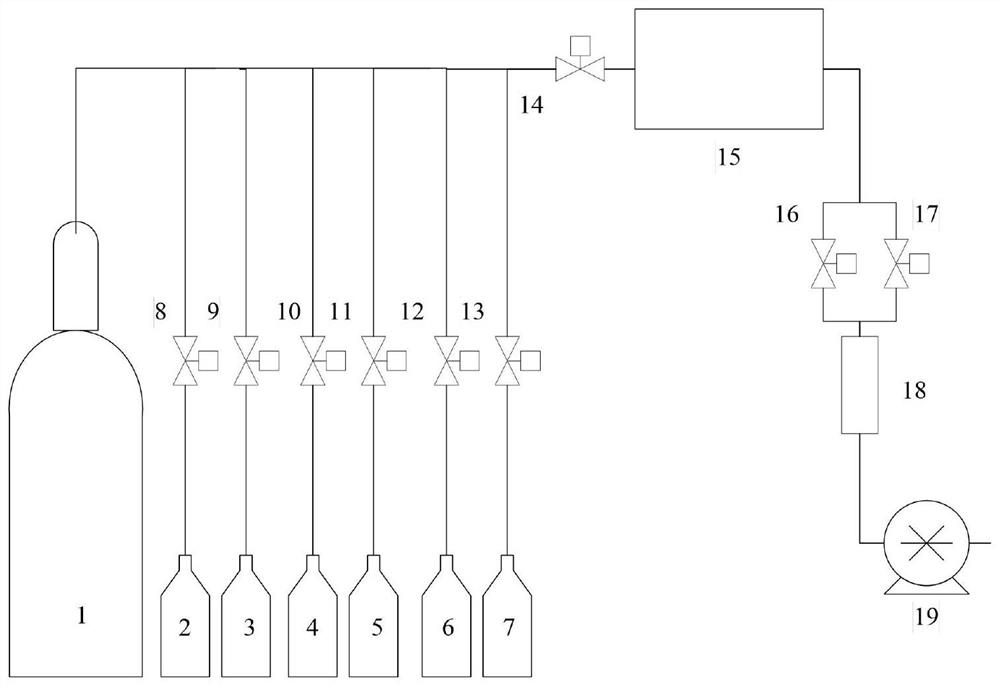

[0054] A method for preparing a functional film layer on the channel inner wall of a super-large aspect ratio microchannel plate, comprising the following steps:

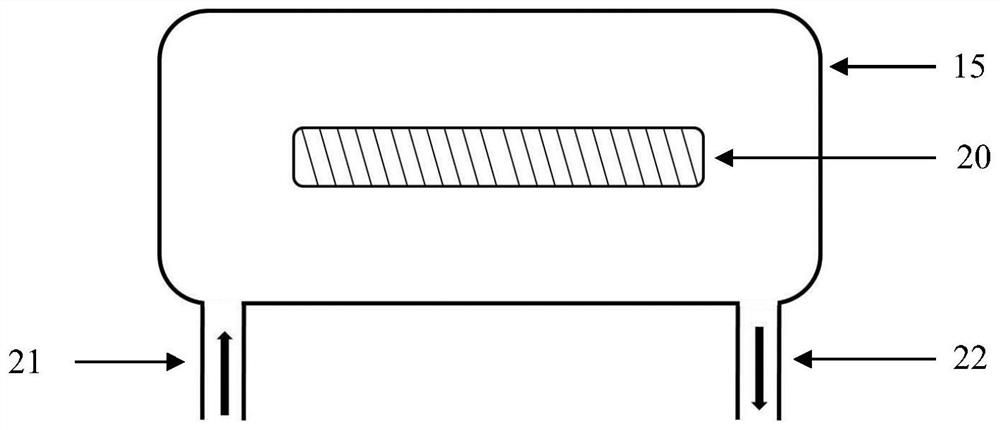

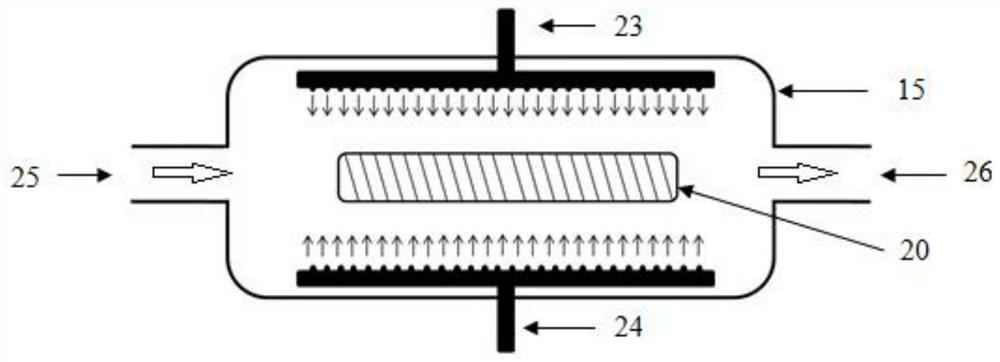

[0055] (1) Put the cleaned micro-channel plate into the fixture and place it in the reaction chamber of the deposition equipment. After vacuuming and purging with nitrogen, heat it up to 150-300°C, and then keep it warm for a certain period of time; in fact, the reaction described above The cavity includes a cavity for placing a microchannel plate. The upper and lower sides of the cavity are respectively equipped with corresponding upper and lower gas uniformity plates, and the left and right sides are respectively equipped with inert gas inlet pipelines and exhaust pipelines. Dense holes are distributed on the plate and the lower gas uniform plate so that the precursor reactants enter the cavity to form two gas curtains, and reach the surface of the microchannel plate at different positions at the same time;

[005...

Embodiment 2

[0071] ALD-MCP with an aspect ratio of 80 to produce aluminum oxide single film deposition process

[0072] (1) Pack the clean microchannel plate after cleaning into a special fixture, place it in the reaction chamber of the deposition equipment, evacuate, set the nitrogen purge flow rate to 300 sccm, and purge through the inlet pipeline 25 and the exhaust pipeline 26, Then heat up to 200°C and keep warm for 2h;

[0073] (2) Enter the TMA precursor: close the pumping valves (16, 17), close the nitrogen purge flow at the same time, open the TMA source pulse valve (8) and last for 2s, the precursor enters the reaction evenly through the upper and lower two gas distribution plates chamber, seal the precursor in the reaction chamber, close the TMA source pulse valve (8), wait for 10s, open the pumping valves (16, 17), open the purge nitrogen flow, and pass through the intake line 25 and the pumping line 26 For purging, the flow rate is set to 1000sccm, and the purging time is 40s...

Embodiment 3

[0077] Deposition process of titanium dioxide + magnesium oxide composite film layer produced by ALD-MCP with an aspect ratio of 500

[0078] (1) Pack the clean microchannel plate after cleaning into a special fixture, place it in the reaction chamber of the deposition equipment, evacuate, set the nitrogen purge flow rate to 300 sccm, and purge through the inlet pipeline 25 and the exhaust pipeline 26, Then heat up to 200°C and keep warm for 2h;

[0079] (2) Enter the titanium tetrachloride precursor: close the pumping valves (16, 17), close the nitrogen purge flow at the same time, open the titanium tetrachloride source pulse valve (11) and continue for 20s, the precursor passes through the upper and lower two uniform The gas plate enters the reaction chamber evenly, seals the precursor in the reaction chamber, closes the pulse valve (11) of the titanium tetrachloride source, waits for 1 min, opens the pumping valves (16, 17), opens the flow rate of purge nitrogen, and passes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com