Polymer conductive silver paste suitable for being printed on substrate, preparation method and application

A technology of conductive silver paste and polymer, which is applied to conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., to achieve the effect of reducing production costs and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A polymer conductive silver paste, comprising the following materials by weight:

[0031] Silver powder 12 parts Copper powder 12 parts Aluminum powder 12 parts

[0032] 1 part tin powder 1 part nickel powder

[0033] 3 parts polyester acrylic

[0034] 6 parts epoxy acrylic resin

[0035] 2 parts benzophenone

[0036] 2 parts benzophenone

[0037] Trimethylolpropane triacrylate 15 parts

[0038] Tripropylene glycol diacrylate 10 parts.

Embodiment 2

[0040] A polymer conductive silver paste, comprising the following materials by weight:

[0041] Silver powder 14 parts Copper powder 14 parts Aluminum powder 14 parts

[0042] 2 parts tin powder 3 parts nickel powder

[0043] 4 parts polyester acrylic resin

[0044] 8 parts epoxy acrylic resin

[0045] 3 parts benzophenone

[0046] 3 parts benzophenone

[0047] Trimethylolpropane triacrylate 25 parts

[0048] 20 parts of tripropylene glycol diacrylate.

Embodiment 3

[0050] A polymer conductive silver paste, comprising the following materials by weight:

[0051] Silver powder 17 parts Copper powder 17 parts Aluminum powder 17 parts

[0052] Tin powder 2 parts Nickel powder 5 parts

[0053] 5 parts polyester acrylic resin

[0054] 10 parts epoxy acrylic resin

[0055] 4 parts benzophenone

[0056] 4 parts benzophenone

[0057] Trimethylolpropane triacrylate 40 parts

[0058] 30 parts of tripropylene glycol diacrylate.

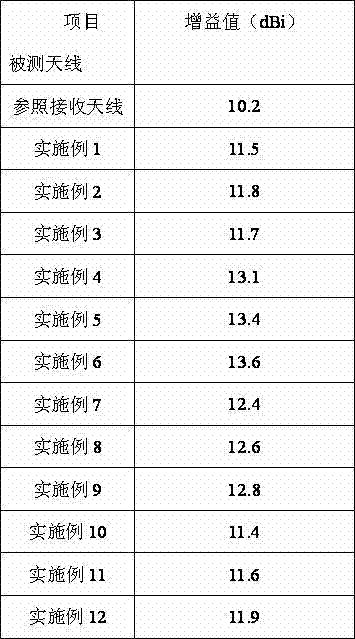

[0059] The above polymer conductive silver paste can also be improved as follows, which can further increase the gain of the receiving antenna, that is, adding 1-2 parts of calcium powder and / or 1-2 parts of zinc powder. The specific ratio is as follows:

[0060] A polymer conductive silver paste, comprising the following materials by weight:

[0061]Silver powder 12-17 parts Copper powder 12-17 parts Aluminum powder 12-17 parts

[0062] Tin powder 1-2 parts Nickel powder 1-5 parts Calcium powder 1-2 parts and / or zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com