Plasma display panel

A display panel and plasma technology, which is applied to alternating current plasma display panels, discharge tubes, electrical components, etc., can solve the problems of long aging time, inability to be practical, and reduced secondary electron emission coefficient, and achieves long life of driving voltage, The effect of low drive voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

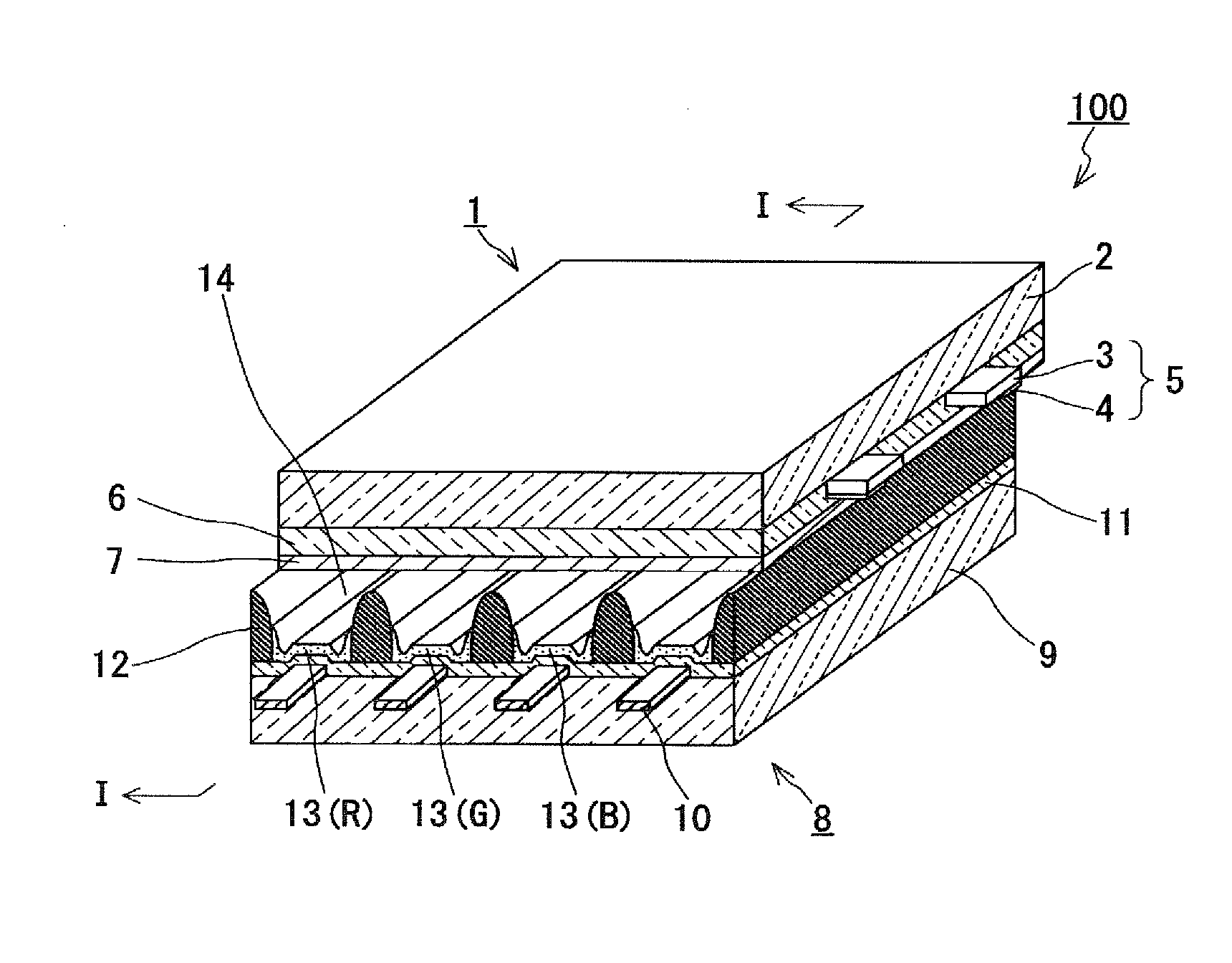

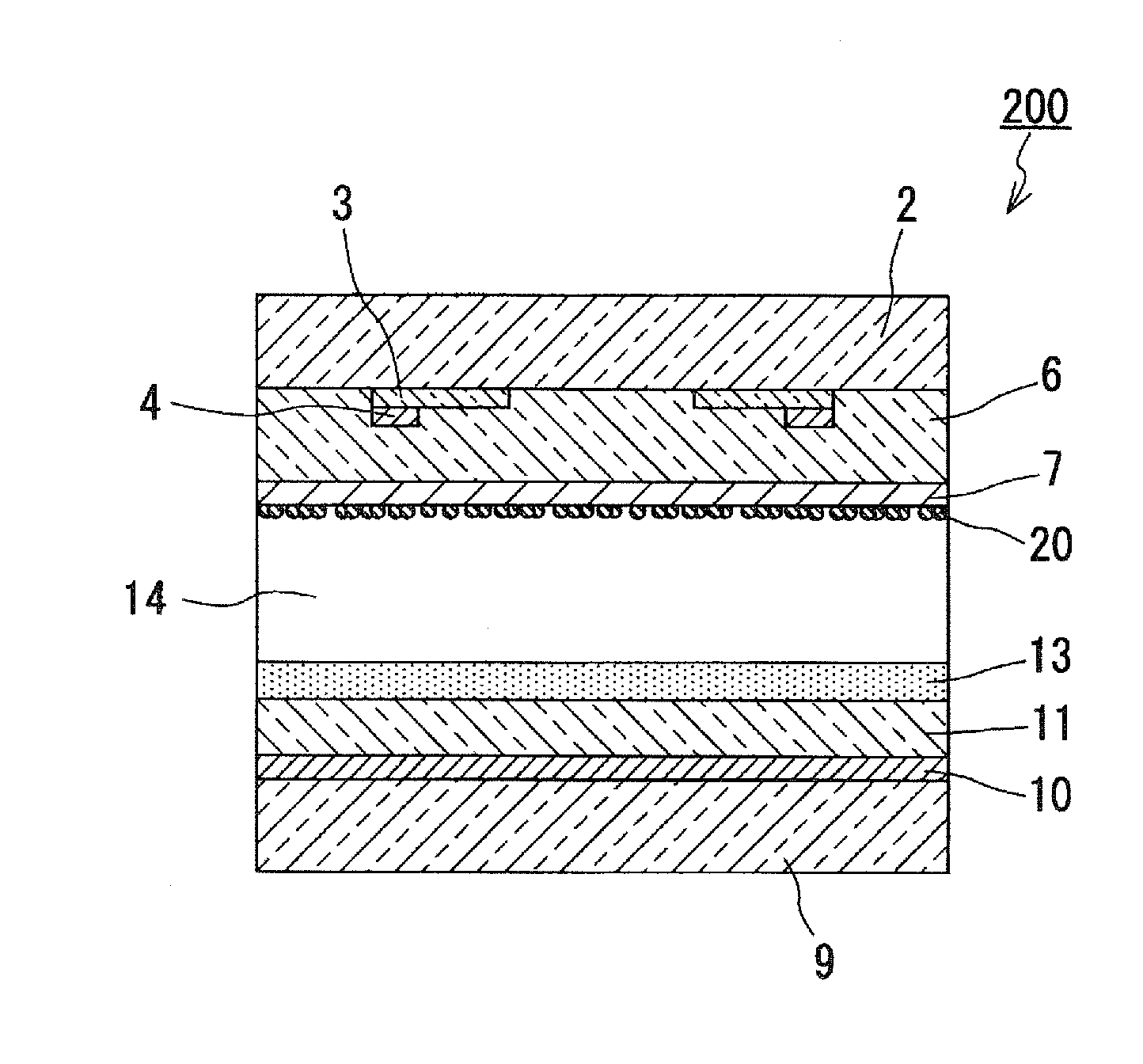

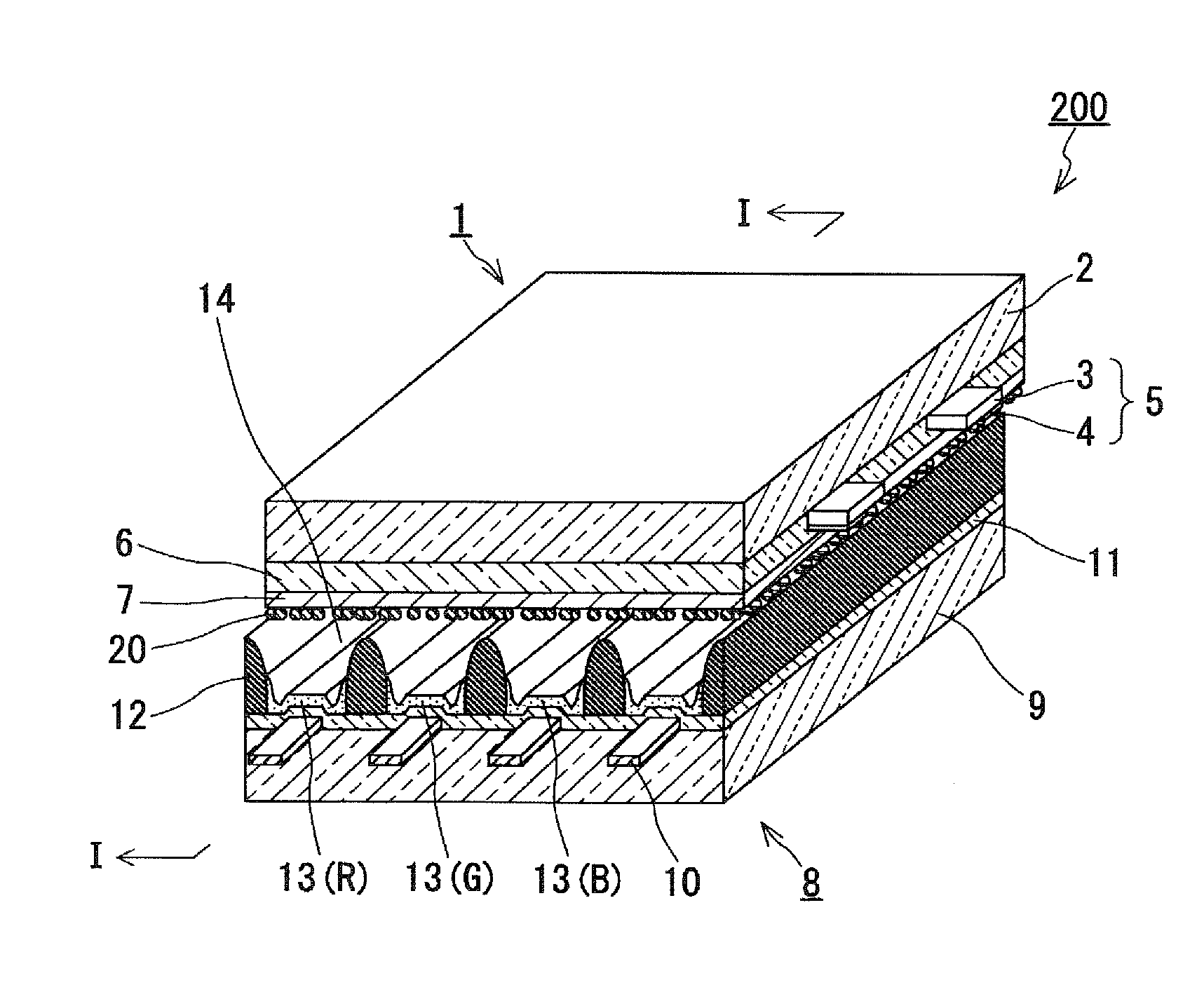

Image

Examples

Embodiment 1

[0085] In this example, the In 2 o 3 React with CaO, SrO, BaO, and rare earth metal oxides to synthesize electron-emitting materials (crystalline compounds) and conduct experiments to confirm the effect of improving chemical stability.

[0086] (Synthesis of crystalline compounds)

[0087] As a starting material, as a reagent special grade or higher CaCO 3 , SrCO 3 、BaCO 3 , a representative of rare earth metal oxides, using La 2 o 3 , Y 2 o 3 , and In 2 o 3 . These raw materials were weighed so that the molar ratio of each metal ion became the value shown in Table 1, wet mixed using a ball mill, and dried to obtain mixed powder. Among them, since only No.6 is In 2 o 3 , so mixing treatment etc. are not particularly performed, nor is subsequent sintering performed.

[0088]Put their mixed powder into an alumina crucible, and sinter in air at 1000-1300°C for 2 hours in an electric furnace. The average particle diameter of the obtained powder was measured, and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com