Atomizing activating process for electroless plating on water-absorbing substrate surface

A water-absorbing, electroless plating technology, applied in the field of electroless plating, can solve the problems of a large amount of waste liquid, easy pollution of activation liquid, cumbersome operation, etc., and achieve the effects of stable activation liquid, saving activation liquid, and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1). Substrate pretreatment: the outer diameter is 1.2cm, the inner diameter is 0.8cm, the length is 10cm, and the water absorption is 460ml / m 2 The porous ceramic tubes were washed with commercially available detergent solution, tap water, and deionized water in sequence, and dried.

[0025] (2). Preparation of activation solution: 0.1gPdCl 2 Add it into 10ml of deionized water, oscillate ultrasonically for 10min, add 40ml of 1M NaOH solution, continue ultrasonically oscillating for 2 hours, and finally obtain a brown-black colloid, in which the palladium content is about 0.01mol / L.

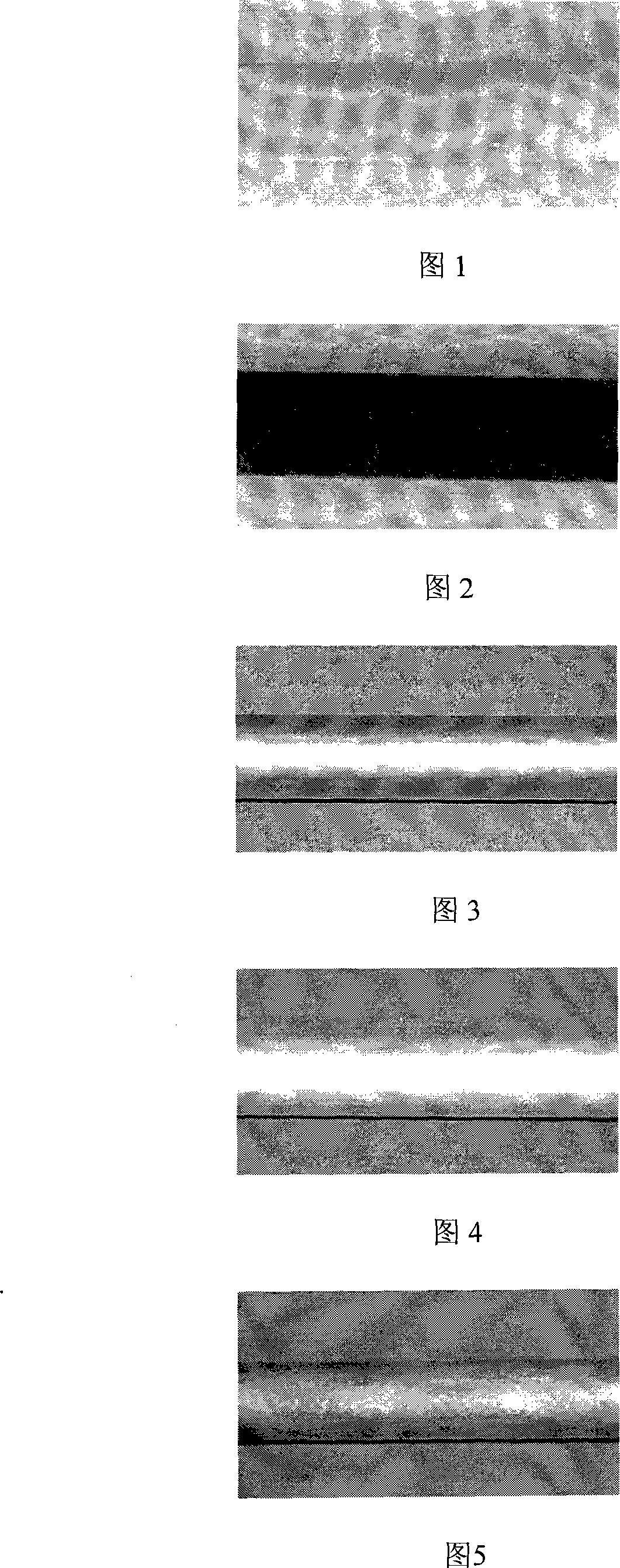

[0026] (3). Activation of the substrate: Spray the activation solution on the outer surface of the ceramic tube with a nitrogen gas flow atomizer (gas pressure 0.2Mpa, nozzle aperture 0.5mm), and rotate the ceramic tube at the same time until the surface presents a uniform brown Yellow (as shown in Figure 1). After drying in the air, place it in a hydrazine solution with a concentration...

Embodiment 2

[0029] (1). The pretreatment of the matrix and the preparation of the activation solution are the same as the steps (1) and (2) of Example 1.

[0030](2). Activation of the substrate: Spray the activation liquid on the outer surface of the ceramic tube with an air flow atomizer (gas pressure 0.4Mpa, nozzle aperture 0.8mm), dry it and place it at 40°C with a concentration of 0.1M hydrazine solution for 5 minutes.

[0031] (3). Electroless silver plating. The composition of the silver plating solution is: 5g / L AgNO 3 , 500ml / L concentrated ammonia water, 35g / L disodium edetate, the coating temperature is 30℃, the reducing agent is 0.5M N 2 h 4 . The prepared silver film is shown in Figure 4.

Embodiment 3

[0033] (1). The pretreatment of the matrix, the preparation of the activation solution and the activation of the matrix are the same as the steps (1) and (2) of Example 1.

[0034] (2). Activation of the substrate: Use an argon gas flow atomizer (gas pressure 0.2Mpa, nozzle aperture 0.5mm) to evenly spray palladium hydroxide colloid on the surface of the substrate, and dry it at 200°C under a hydrogen atmosphere Restore for 5 minutes.

[0035] (3). Electroless nickel plating. The composition of the nickel plating solution is: 30g / L NiSO 4 ·6H 2 O, 250ml / L concentrated ammonia water, the coating temperature is 60°C, and the reducing agent is 0.5M N 2 h 4 . The prepared nickel film is shown in Figure 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com