Method for fusing and reducing iron by employing iron ore hot pressing carbon-containing agglomerate

An agglomeration and shaft furnace technology, which is applied in shaft furnaces, furnaces, furnace types, etc., can solve the problem of increasing the cost of binders and slag volume, poor high temperature strength, limiting the application of cold-solidified carbon-containing pellets smelting reduction technology and development and other issues, to achieve the effects of good controllability, long furnace service life, and strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

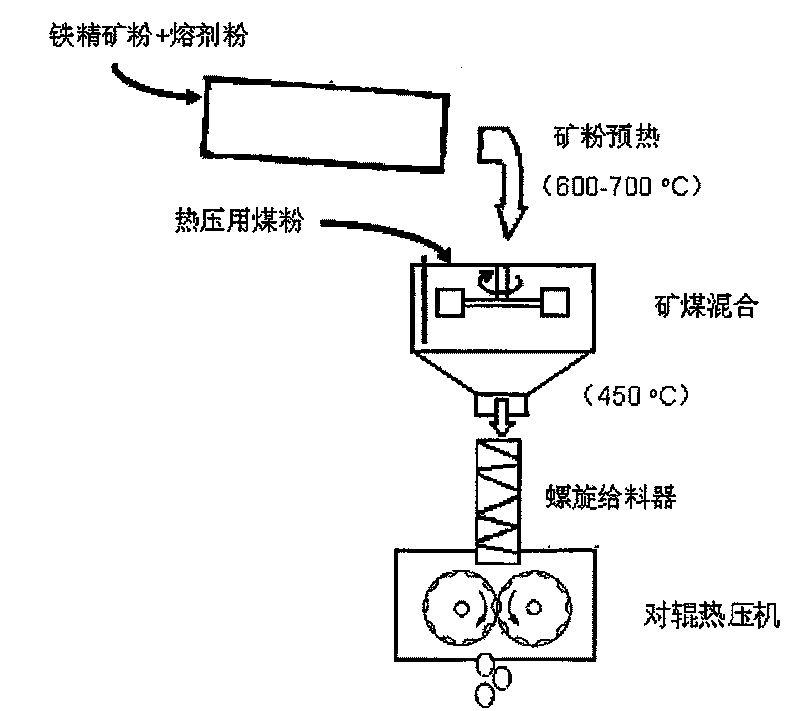

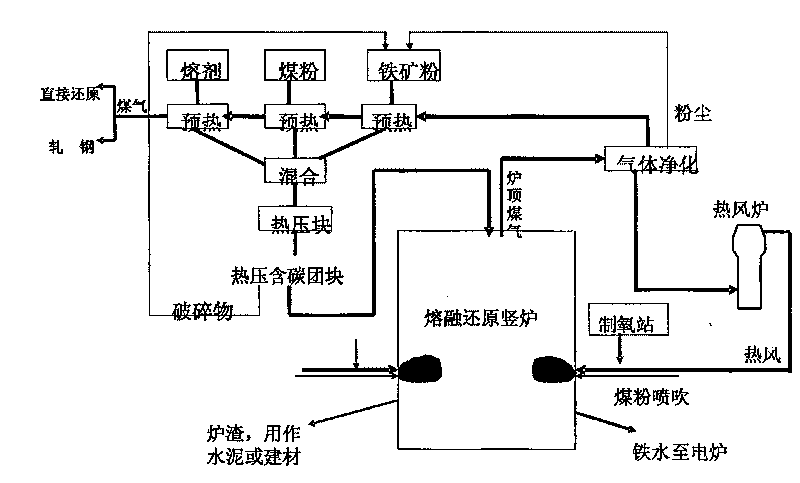

Method used

Image

Examples

Embodiment Construction

[0020] Main raw material is as follows in the technological process of the present invention:

[0021] 1) Iron-containing powder. Comprehensively considering the technical and economic indicators of the entire process, the smooth flow of shaft furnace production, and the connection between upstream and downstream processes, the selected iron-containing powder should have high grade, low gangue content, low phosphorus and sulfur content, good reducibility, and particle size. suitable. This process uses iron ore concentrate powder (Dashiqiao iron ore concentrate), the main components are shown in Table 1, and the place of origin is Dashiqiao, Liaoning.

[0022] Table 1 Dashiqiao iron concentrate composition (wt%)

[0023] project

T Fe

SiO 2

Al 2 o 3

CaO

MgO

S

P

other

Dashiqiao Iron Concentrate

70.09

1.75

0.085

0.15

0.10

0.31

0.01

<0.021

[0024] 2) Coal for hot pressing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com