High heat-resisting ceramic cooking cook ware suitable for electromagnetic induction furnace

An electromagnetic induction furnace, high heat-resistant technology, applied in the direction of special materials for cooking utensils, etc., can solve the problems of not delicious cooking, poor working stability, poor heat preservation performance, etc., and is suitable for mass industrial production and simple manufacturing equipment , excellent thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

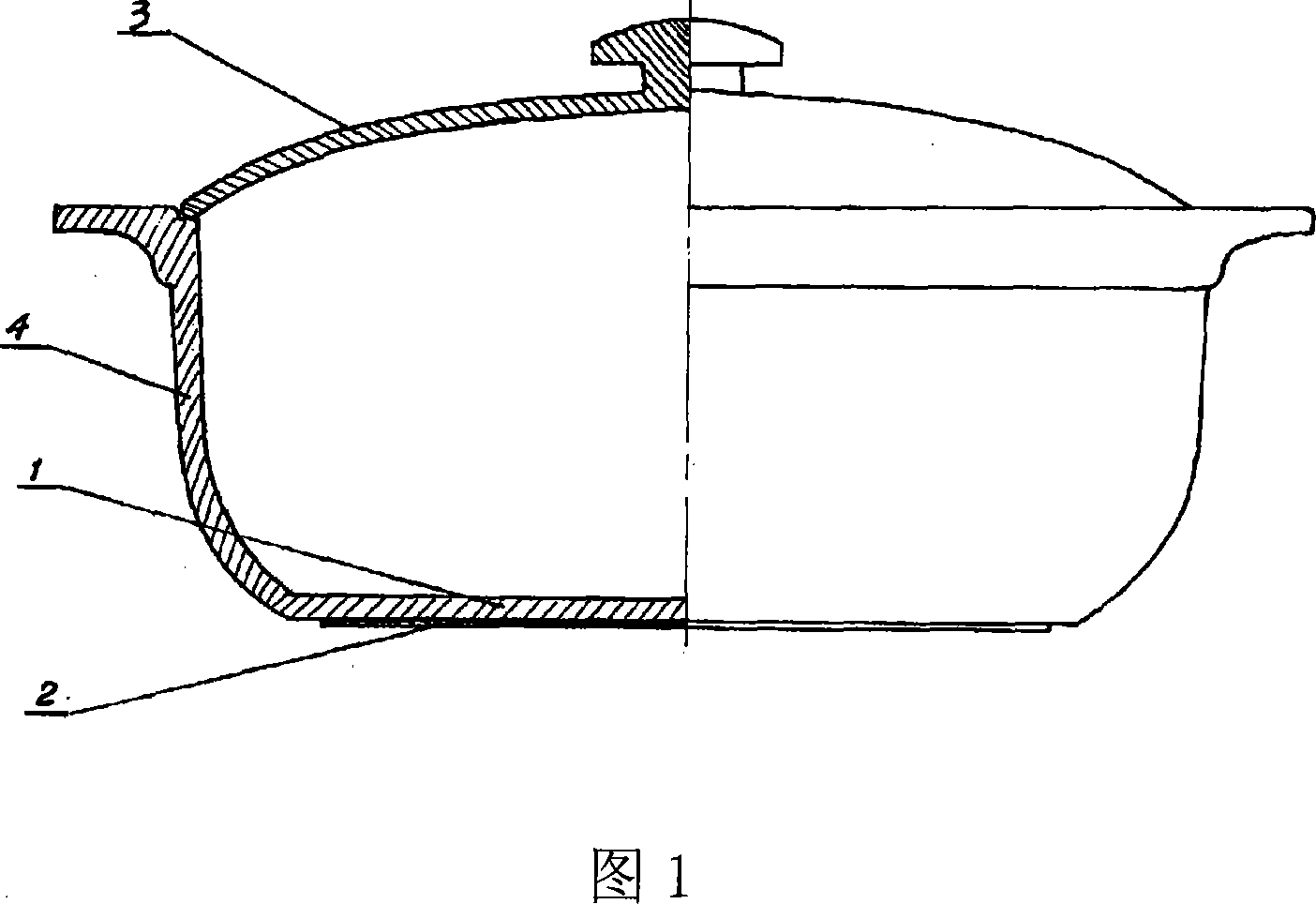

Image

Examples

Embodiment 1

[0029] 1. Take each mineral raw material according to the batching amount, which contains (% by weight) lithium-containing mineral raw material spodumene 30%, spodumene feldspar 30%, eucryptite 1%, quartz 7%, kaolin 30%, calcined talc 2% %, after 12 hours of ball milling, the fineness is 250 mesh, and then after dehydration, vacuum mud treatment, molding, drying and glazing, it is oxidized and sintered in a liquefied gas kiln at a high temperature. The sintering temperature is 1310°C and the sintering time is 6 hours. , wherein 45 minutes at 1150°C, 30 minutes at the highest temperature, and cooled for later use.

[0030] 2, take each coating raw material, far-infrared radiation coating contains (weight %) cordierite 15, the high-temperature composition 35 of transition metal oxides such as iron cobalt chromium copper, inorganic flux 50; Electromagnetic induction eddy current heating coating contains ( % by weight) metal silver powder 91, iron-chromium-nickel-aluminum alloy po...

Embodiment 2

[0035]1. Take each mineral raw material according to the batching amount, which contains (% by weight) lithium-containing mineral raw material spodumene 30%, spodumene feldspar 35%, eucryptite 5%, quartz 5%, kaolin 28%, calcined talc 2 %, after 13 hours of ball milling, the fineness is 280 mesh, and then after dehydration, vacuum mud treatment, molding, drying and glazing, it is oxidized and sintered in a liquefied gas kiln at a high temperature. The sintering temperature is 1330°C and the sintering time is 6.5 hours. , where the temperature is 1150°C for 60 minutes, the highest temperature is 40 minutes, and cooled for later use.

[0036] 2, take by weighing each coating raw material, far-infrared radiation coating contains (weight %) cordierite 7.5, high-temperature compound 42.5 of transition metal oxides such as iron cobalt chromium copper, inorganic flux 50; Electromagnetic induction eddy current heating coating contains ( % by weight) metal silver powder 82, based on iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com