A manufacture method of carbon-based metal nitrides, and carbonide supercapacitance material

A technology of nitrides and carbides, which is applied in the field of preparation of supercapacitor electrode materials, can solve the problems of no preparation of metal nitrides and carbide materials, no preparation methods of carbon-based metal nitrides, etc., and achieve easy implementation and large specific capacitance. , The effect of polarization preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

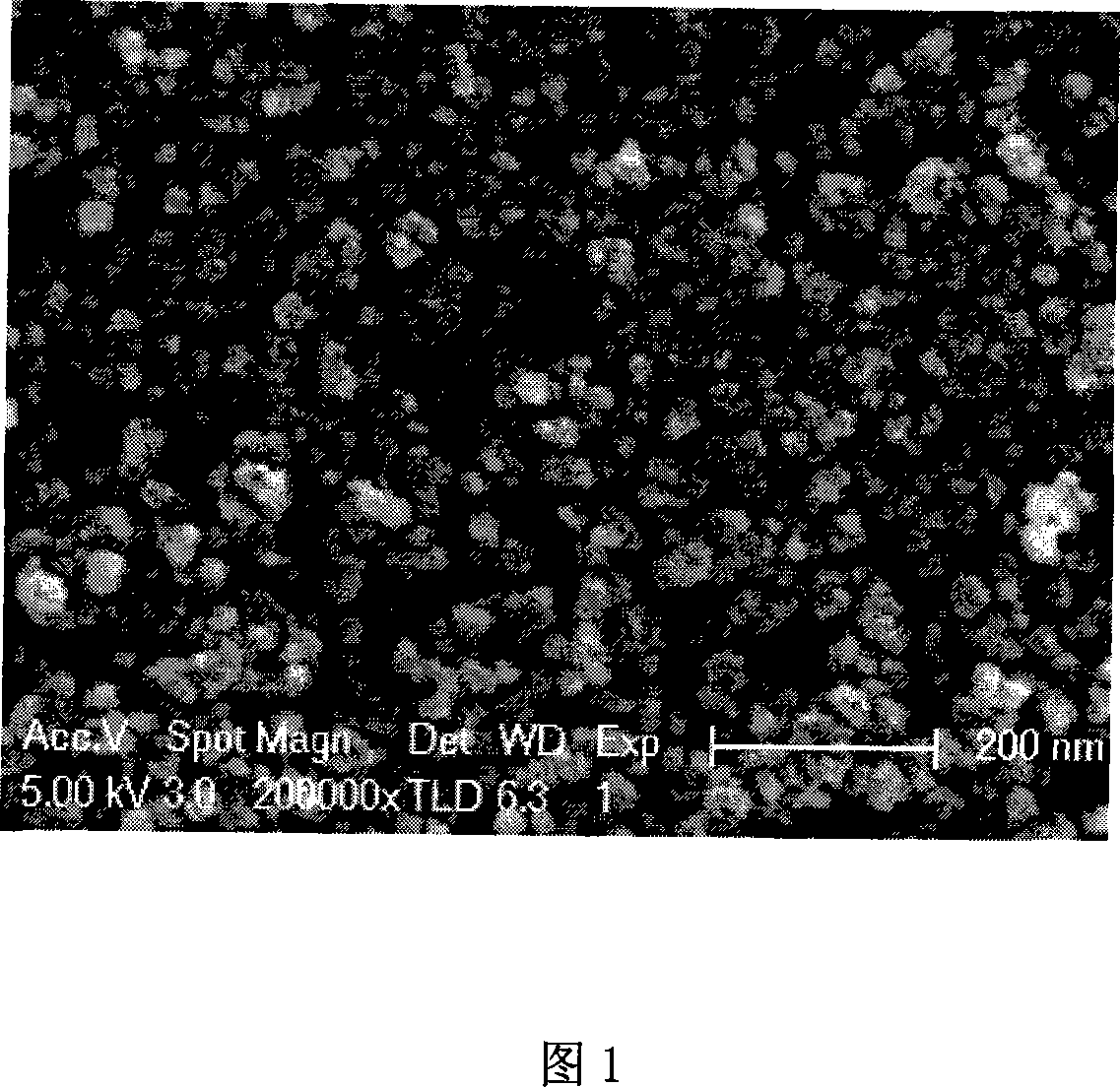

Image

Examples

Embodiment 1

[0036] The molar ratio R / F of resorcinol to formaldehyde is 0.4, the molar ratio R / C of resorcinol to additive sodium acetate is 50, the mass ratio of resorcinol to added water is 0.1, potassium metavanadate (KVO 3 ) to a mass ratio of resorcinol of 0.7. Dissolve resorcinol in deionized water, then add additive sodium acetate, then add formaldehyde solution, and mix well. placed in a sealed reactor. The constant temperature was 85°C, and after 0.3 hours, potassium metavanadate (KVO 3 ), mixed evenly, and the solution became a hydrogel after 3 hours. Adjust the temperature of hydrazine to 80° C., pass ammonia gas through the hydrazine, and the nitriding gas that comes out is a mixture of ammonia and hydrazine, wherein the mass content of hydrazine is 6%. Under the action of nitriding gas, keep the temperature at 850°C for 6 hours to obtain the product—carbon-based vanadium nitride with high specific surface area. at 1% O 2 Passivation in ammonia gas for 5 hours, and then ...

Embodiment 2

[0039] The molar ratio R / F of resorcinol and formaldehyde is 0.5, the mol ratio R / C of resorcinol and additive sodium acetate is 100, the mass ratio of resorcinol and the water that adds is 0.2, manganese chloride ( MnCl 2 ) to a mass ratio of resorcinol of 0.7. Dissolve resorcinol in deionized water, then add additive sodium acetate, then add formaldehyde solution, and mix well. placed in a sealed reactor. The constant temperature was 80°C, and after 1 hour, manganese chloride (MnCl 2 ), mixed evenly, and the solution became a hydrogel after 7 hours. The nitriding gas is a mixed gas of ammonia and hydrazine (wherein the mass content of hydrazine is 6%), at 800° C., at a constant temperature for 2 hours, to obtain the product—carbon-based manganese nitride with high specific surface area. at 0.2% O 2 Passivation in ammonia gas for 5 hours, and then put the sample in a desiccator for later use.

[0040] A three-electrode system was used to test the specific capacitance of...

Embodiment 3

[0042] The mol ratio R / F of resorcinol and formaldehyde is 0.4, the mol ratio R / C of resorcinol and additive sodium acetate is 200, the mass ratio of resorcinol and the water that adds is 0.2, ammonium molybdate ( (NH 4 ) 6 Mo 7 o 24 4H 2The mass ratio of O) to resorcinol is 0.1. Dissolve resorcinol in deionized water, then add additive sodium acetate, then add formaldehyde solution, and mix well. placed in a sealed reactor. The constant temperature was 80°C, and after 2 hours, ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 0), mix homogeneously, and then become hydrogel through 18 hours solution. Nitriding gas is ammonia and ethylenediamine (wherein the mass content of ethylenediamine is 5%) (H 2 NCH 2 CH 2 NH 2 ) mixed gas at 900°C for 3.5 hours at a constant temperature to obtain the product—carbon-based molybdenum nitride with high specific surface area. at 0.5% O 2 Passivation in ammonia gas for 5 hours, and then put the sample in a desiccator for later use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com