A method for determining proton exchange film fuel cell film electrode platinum loading

A fuel cell membrane and proton exchange membrane technology, applied in the field of platinum load analysis, can solve the problem of not providing a sample processing method, and achieve the effects of small analysis error, large sample weighing and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Sample Processing

[0033] (1) Sampling: Take a piece of undamaged and dry MEA of about 1g, accurately measure its size and mass, carefully cut it into pieces with scissors, and then completely transfer it to a corundum crucible. Sample size measurement must be accurate as it is closely related to calculating the theoretical platinum content of the sample.

[0034] (2) Sample carbonization and ashing: Put the crucible with the MEA on the lid and put it into the muffle furnace, pay attention to the ventilation of the muffle furnace. First carbonize at 400°C for 2 hours. Then it is ashed at 900°C for more than 12 hours. Fully ash the carbon in the MEA sample. After fully ashing, there is only a little residue left on the bottom of the crucible, and its surface is off-white, which adheres to the bottom of the crucible in the form of dry powder.

[0035](3) Sample nitration: after the ashed sample is cooled to room temperature, wet the dry powder with a small amount ...

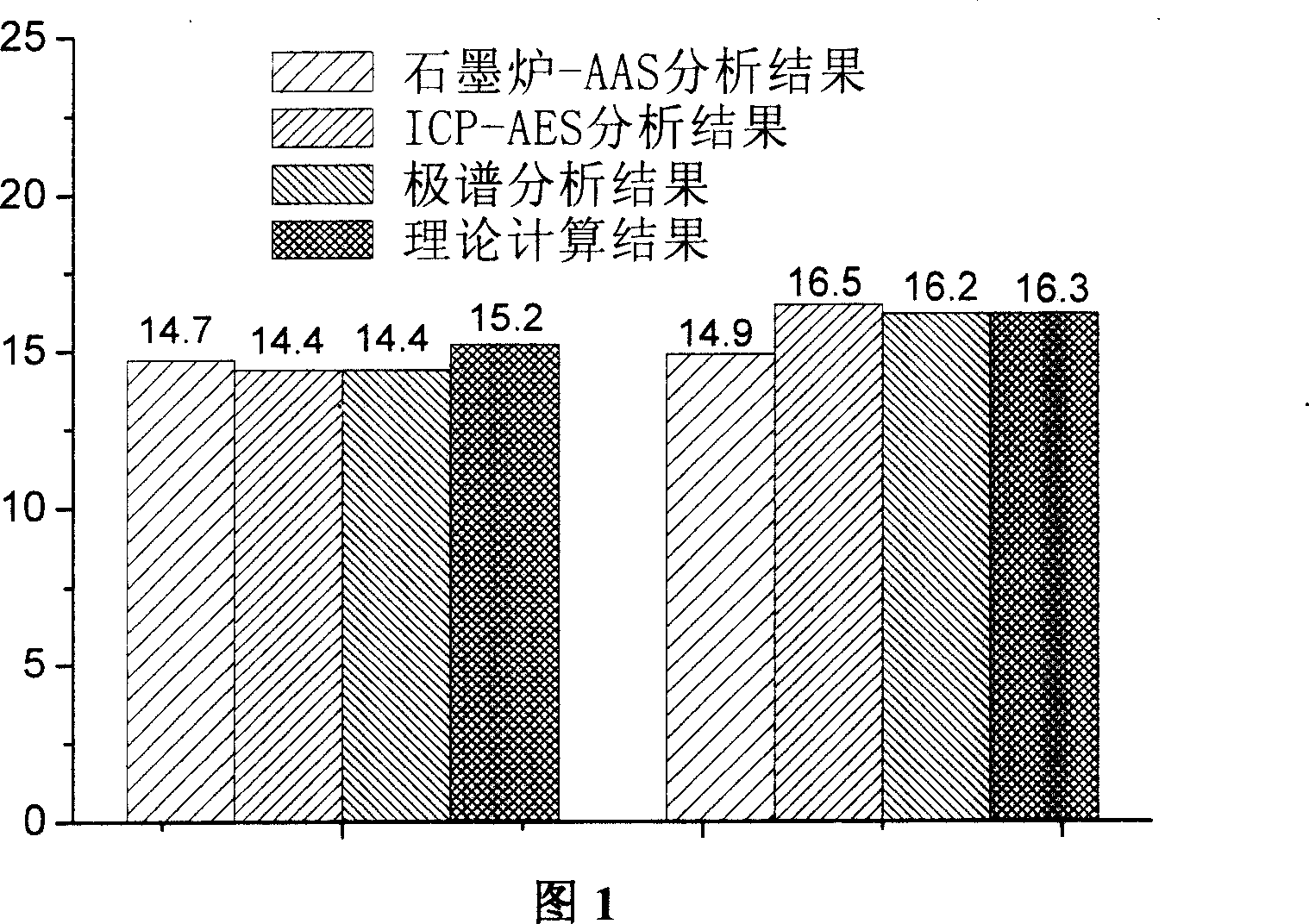

Embodiment 2

[0048] Take two undamaged and dry MEAs of about 1g, measure their size and mass accurately, cut them carefully with scissors, and then transfer them completely to a corundum crucible. Sample size measurement must be accurate as it is closely related to calculating the theoretical platinum content of the sample. Cover the crucible with the MEA and put it into the muffle furnace, pay attention to the ventilation of the muffle furnace. First carbonize at 400°C for 2 hours. Then, it was ashed at 900° C. for 12 hours to fully ash the carbon in the MEA sample. After fully ashing, there is only a little residue left on the bottom of the crucible, and its surface is off-white, which adheres to the bottom of the crucible in the form of dry powder. After the ashed sample is cooled to room temperature, wet the dry powder with a small amount of water, then slowly add an appropriate amount of concentrated sulfuric acid and concentrated nitric acid (volume ratio 1:1) along the crucible wa...

Embodiment 3

[0052] Take two undamaged and dry single electrodes of about 1g (either anode or cathode), accurately measure their size and mass, carefully cut them into pieces with scissors, and then completely transfer them to a corundum crucible. Sample size measurement must be accurate as it is closely related to calculating the theoretical platinum content of the sample. Cover the crucible with the MEA and put it into the muffle furnace, pay attention to the ventilation of the muffle furnace. First carbonize at 400°C for 2 hours. Then, it was ashed at 900° C. for 12 hours to fully ash the carbon in the MEA sample. After fully ashing, there is only a little residue left on the bottom of the crucible, and its surface is off-white, which adheres to the bottom of the crucible in the form of dry powder. After the ashed sample is cooled to room temperature, wet the dry powder with a small amount of water, then slowly add an appropriate amount of concentrated sulfuric acid and concentrated n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com