Emulsification asphalt used for high speed railway or light rail plate type slag-free orbit CA mortar

A technology of emulsified asphalt and ballastless track, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of complex preparation process, narrow temperature adaptation range, easy stratification, etc., and achieves good storage stability and suitable working time. , the effect of easy transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 (by weight part)

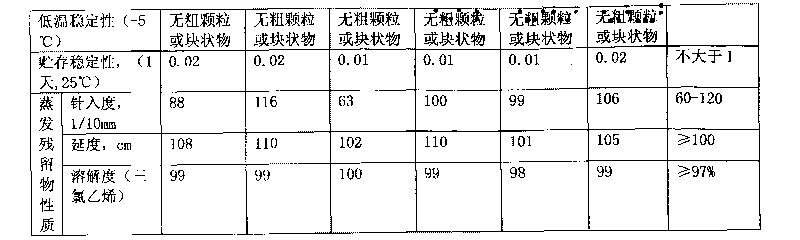

[0031] Take 50.0 parts of No. 90 heavy traffic road asphalt, 4.0 parts of cationic surfactant coconut oil amine, 6.0 parts of nonionic surfactant coconut acid diethanolamide, 0.15 parts of stabilizer strontium chloride, 1.85 parts of additive polyvinyl alcohol, water 38.0 servings. Heat the above asphalt to 150°C, dissolve the additive polyvinyl alcohol in boiling water, cool to 60°C, dissolve other components in the aqueous solution of polyvinyl alcohol to form a mixed aqueous solution, and then pass the asphalt and the aqueous solution through the emulsification equipment The emulsified asphalt was obtained, and the properties of the product are shown in Table 1.

Embodiment 2

[0032] Embodiment 2 (by weight part)

[0033] Get 52.0 parts of No. 120 straight run pitch, 6.5 parts of cationic surfactant 1-aminoethyl-2-heptadecylimidazoline-2 hydrochloride, nonionic surfactant polyoxyethylene (20) sorbitol mono-oil Ester (T-80) 6.0 parts, stabilizer ferrous sulfate 0.2 parts, additive cationic guar gum 2.0 parts, water 33.3 parts. Heat the above asphalt to 150°C, dissolve the additive cationic guar gum in water at 40°C, and dissolve other components in the cationic guar gum aqueous solution to form a mixed aqueous solution, and then pass the asphalt and the aqueous solution through the emulsification equipment The emulsified asphalt was obtained, and the properties of the product are shown in Table 1.

Embodiment 3

[0034] Embodiment 3 (by weight part)

[0035] Take 48.0 parts of Daqing propane deoiled asphalt, 5.0 parts of cationic surfactant hydrogenated tallow propylene diamine, 5.0 parts of nonionic surfactant nonylphenol polyoxyethylene ether (20), 0.1 part of stabilizer ammonium sulfate, additive hydroxyl 2.5 parts of ethyl cellulose, 39.4 parts of water. Heat the above asphalt to 150°C, dissolve the additive hydroxyethyl cellulose in water at 40°C, and dissolve other components in the aqueous solution of hydroxyethyl cellulose to form a mixed aqueous solution, and then pass the asphalt and the aqueous solution through the emulsification equipment The emulsified asphalt was obtained, and the properties of the product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com