Method for producing semi-solid state sizing agent for founding and the producing device

A semi-solid slurry and rheological casting technology, which is applied in the field of materials, can solve the problems of high cost and complex equipment, achieve low cost, increase the fracture rate and split rate, and improve the effect of heat exchange conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this example, aluminum alloy semi-solid slurry is prepared, and the grade of the alloy used is ZL101.

[0029] This embodiment adopts the method of directly using the heat capacity of the deflector to cool the molten metal, which is suitable for the production of a small amount of semi-solid slurry at a time, and can directly use the heat capacity of the copper tube to quench the alloy liquid.

[0030] In practice, the molten metal is introduced into the mold through a high thermal conduction deflector with cooling effect, the temperature of the deflector is controlled below the liquidus temperature of the alloy, and the molten metal crystallizes on the inner wall of the deflector to grow into The dendrite morphology is broken by the liquid flow and enters the liquid phase to form a semi-solid slurry.

[0031] The device (accompanying drawing 1) of implementing this method comprises molten metal insulation crucible 3, deflector 2 and mold 1. Wherein, the deflector 2...

Embodiment 2

[0036] This example is to prepare magnesium alloy semi-solid slurry, and the grade of alloy used is ZM5.

[0037] In this embodiment, a thermostat is installed on the outer wall of the deflector to forcibly cool the deflector, which is suitable for the production of large quantities of semi-solid slurry.

[0038] In practice, the molten metal is introduced into the mold through a high thermal conduction deflector with cooling effect, and the temperature controller installed on the outer wall of the deflector is used to force the molten metal attached to the inner wall of the deflector. After cooling, the molten metal crystallizes and grows into a developed dendrite morphology on the inner wall of the deflector, which is washed and broken by the liquid flow and then enters the liquid phase to form a semi-solid slurry.

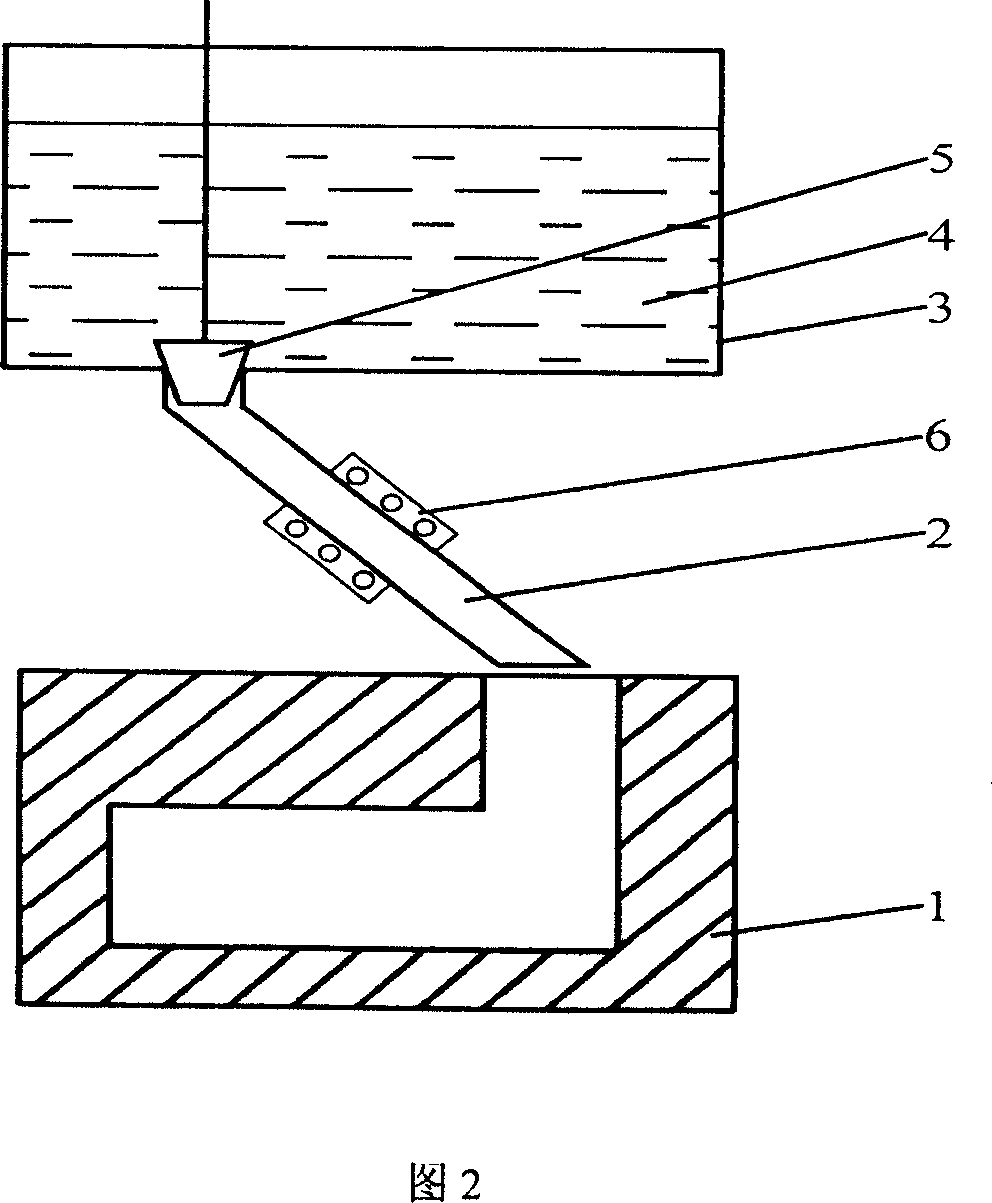

[0039] The device (accompanying drawing 2) that implements this method comprises molten metal insulation crucible 3, deflector 2, thermostat 6 and mold 1, where...

Embodiment 3

[0044] In this example, a magnesium alloy semi-solid slurry is prepared, and the grade of the alloy used is AZ91.

[0045] This embodiment adopts the method of installing a vibrating device on the outer wall of the deflector to force the deflector to vibrate, which is suitable for the production of small batches of high-quality semi-solid slurry.

[0046] In practice, the molten metal is introduced into the mold through a high thermal conduction deflector with cooling effect, the temperature of the deflector is controlled below the liquidus temperature of the alloy, and the molten metal crystallizes on the inner wall of the deflector to grow into The dendrite morphology is broken by the liquid flow and enters the liquid phase. Through the vibrating device installed on the outer wall of the deflector, the solid phase metal attached to the inner wall of the deflector is forced to vibrate, so that the solid phase adhered to the inner wall of the deflector is broken, and the solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com