Constituting method for metal ordered structure surface reinforced base

A technology of ordered structure and surface enhancement, applied in the fields of nanostructure fabrication, Raman scattering, nanotechnology, etc., can solve the problems of expensive instruments, limited application, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

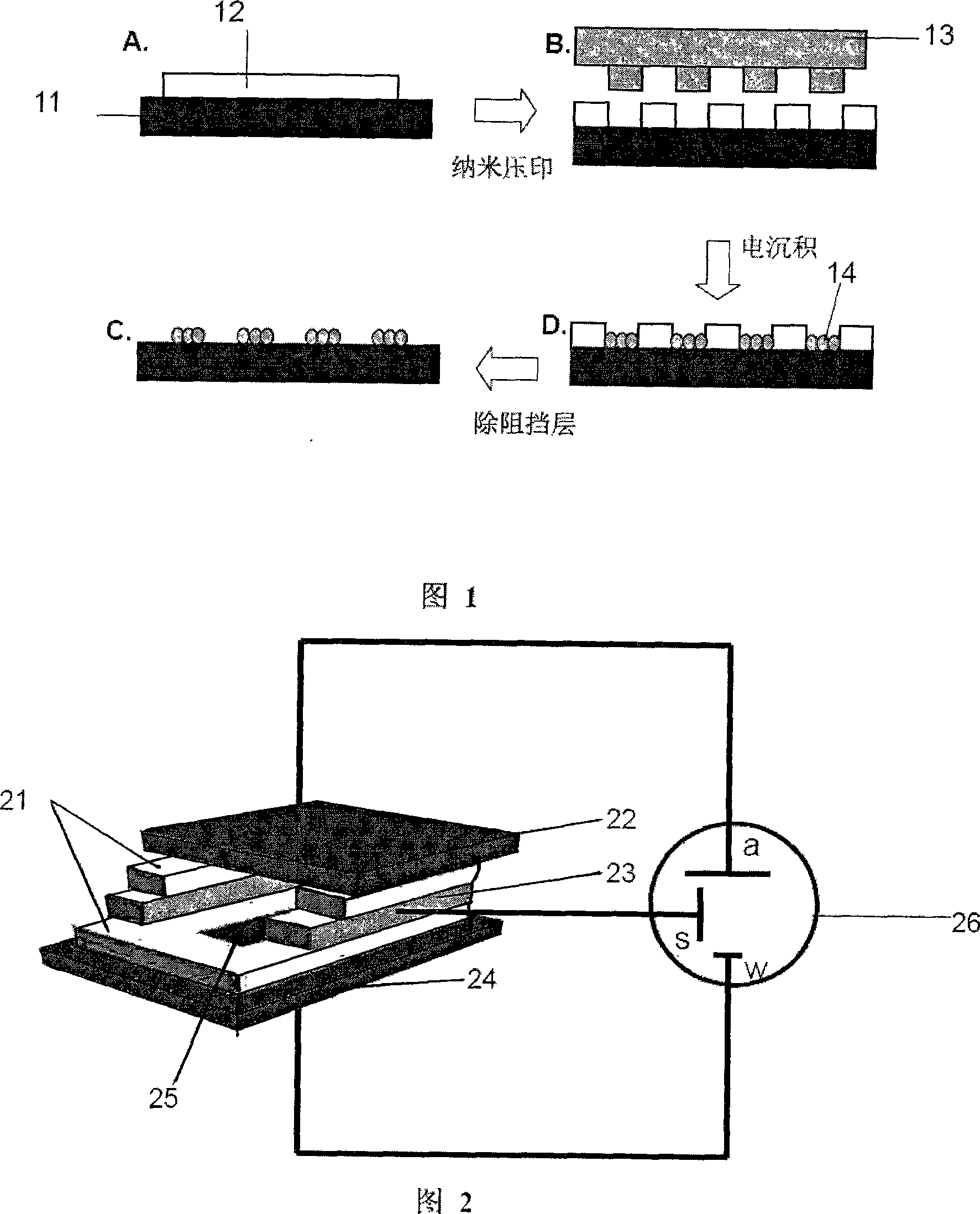

[0091] Take a small amount of thermoplastic polymer MRI-7030 (Micro Resist Company, Germany) and spin-coat it on the treated ITO surface. The spin-coating thickness is about 300nm. Acetone, ethanol and high-purity water were ultrasonically cleaned for 5 minutes, dried with high-purity nitrogen, and then treated with oxygen plasma at a power of 200 mW for 3 minutes to activate the ITO surface. Using the 2.5-inch nano-imprinting machine produced by Sweden's OBDUCAT company, the template of silicon nitride material (constructed by electron beam etching method, its structure is divided into two parts, one part is a lattice structure, the size of the point The range is 800nm×800nm~10μm×10μm, and the pitch size range of dots is 800nm~10μm; the other part is a strip structure, whose line width and line spacing are 800nm~10μm) to build a complementary structure of polymer and template Ordered structure, that is, the use of nanoimprinting method to build microstructures on the surface ...

Embodiment 2

[0095] Take a small amount of polymethyl methacrylate PMMA (sigma-aldrich) and spin-coat it on the treated ITO surface. The spin-coating thickness is about 300nm. Ultrasonic cleaning for 5 minutes, drying with high-purity nitrogen, and using oxygen plasma at a power of 200 mW for 3 minutes to activate the ITO surface. Using the 2.5-inch nano-imprinting machine produced by Sweden's OBDUCAT company, the template of silicon nitride material (constructed by electron beam etching method, its structure is divided into two parts, one part is a lattice structure, the size of the point The range is 800nm×800nm~10μm×10μm, the pitch size range of dots is 800nm~10μm, and the other part is a strip structure, whose line width and line spacing are 800nm~10μm) to build a complementary order of polymer and template structure Structure (one part is a concave dot matrix structure, and its size ranges from 800nm×800nm to 10μm×10μm, and the pitch is 800nm to 10μm; the other part is a strip str...

Embodiment 3

[0097] Spin-coat a small amount of polystyrene PS (sigma-aldrich) on the treated ITO surface with a spin-coating thickness of about 300nm. The treatment method is to cut the ITO into a size of 2cm×2cm, and then use acetone, ethanol and high-purity water to ultrasonically clean it for 5min. , after blowing dry with high-purity nitrogen gas, use oxygen plasma to activate the ITO surface with a power of 200mW for 3min. Using the 2.5-inch nano-imprinting machine produced by Sweden's OBDUCAT company, the template of silicon nitride material (constructed by electron beam etching method, its structure is divided into two parts, one part is a dot matrix structure, the size of the dots The range is 800nm×800nm~10μm×10μm, the pitch size range of dots is 800nm~10μm, and the other part is a strip structure, whose line width and line spacing are 800nm~10μm) to build a complementary order of polymer and template structure Structure (one part is a concave dot matrix structure, and its size r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com